Warning, 1 system components – SkyTrak 6036 Service Manual User Manual

Page 195

Section 10.

Electrical System

Model 6036 S/N 9B0499 and Before

10-2

10.1.1

Service Warnings

and Recommendations

• DO NOT disconnect the battery while the

engine is running. This will cause a voltage

surge in the alternator charging system that

will immediately ruin the diodes or transistors.

• DO NOT disconnect any wiring without first

stopping the engine, turning all electrical

switches to the OFF position and disconnect-

ing the battery ground cable from the battery.

• DO NOT cause a short circuit by connecting

leads to incorrect terminals. Always identify

a lead to its correct terminal. A short circuit

or wrong connection giving reverse polarity

will immediately and permanently ruin

transistors and diodes.

• DO NOT connect a battery into the system

without checking for correct polarity and

voltage.

• DO NOT “flash” connections to check for

current flow. No matter how brief the contact

the transistors may be ruined.

• Wear safety glasses when working near

batteries.

• All lead-acid batteries generate hydrogen gas

which is highly flammable. If ignited by a

spark or flame, the gas may explode violently

causing spraying of acid, fragmentation of the

battery, and possible severe personal

injuries, particularly to the eyes.

• Avoid battery acid. In case of contact with

acid, flush immediately with water.

• Charge batteries only in a well-ventilated

area. Always be sure battery chargers are

OFF when connecting to or disconnecting

from batteries.

• See Delco Remy Service Bulletin 1B115 and

1B-116 for additional safety information and

procedures.

These instructions assume that all wires are

connected and routed as designed. Take into

account any disconnected and rerouted wires

before you begin any diagnosis. By referring to

the wiring diagrams, you can test circuits for

continuity or shorts by using a conventional test

light, ohmmeter, multimeter or low reading voltme-

ter.

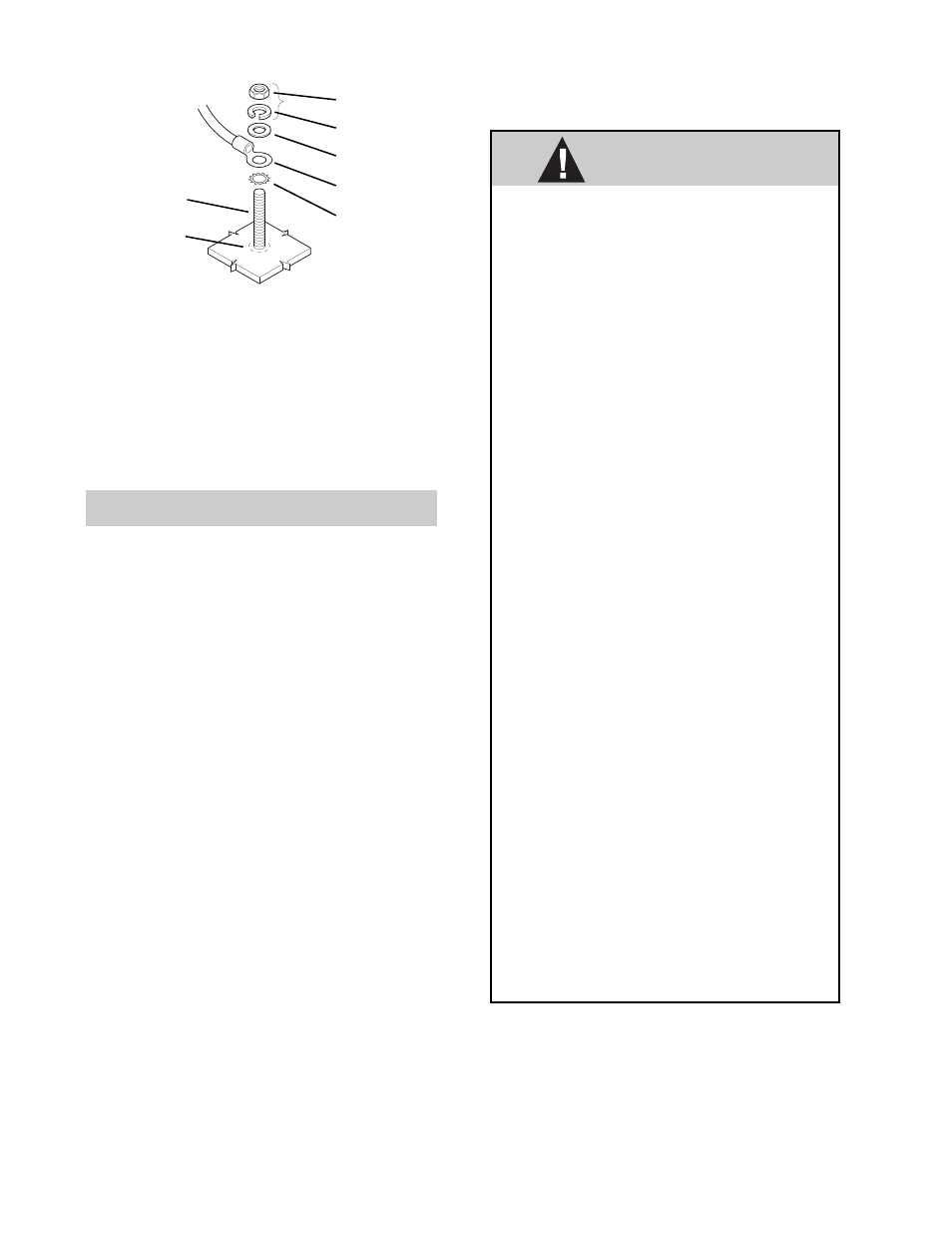

Warning !

A.

The area around the base of the stud (the outside

diameter of lock washer (5)) shall be free of paint.

B.

Stud, bolt, or capscrew

1.

Hex nut or lock nut

2.

Tooth or slot type lock washer

3.

Flat washer

4.

Electrical ground or grounds

5.

Tooth type lock washer

Fig. 10.1 Recommended Sequence of Parts for

Electrical Wire Grounding

10.1 SYSTEM COMPONENTS

The electrical system produces, stores, distributes

and uses electricity in the operation of the forklift.

Electricity is produced by an engine-driven alterna-

tor which has a solid state voltage regulator.

Current from the alternator charges the battery

and powers components.

The battery provides power for starting the engine

and supplements the output of the alternator

during periods of peak demand.

Other electrically powered components include a

horn, neutral start switch, steer select valve; park

lock release valve, reverse switch and backup

alarm; an hourmeter, a fuel level sender and

gauge, and a cluster of warning lights.

A forklift may have the following electrical options:

• a lighting system with headlights, tail lights,

directional signals, emergency flashers and

rear work light;

• an enclosed cab with air circulating and

heater fans and a windshield washer and

wiper

NOTE: Forklifts built thru Serial Number 9B0499

have an electrically powered hydraulic pump. This

pump maintains hydraulic pressure for power

steering and service and park lock brakes if

engine oil pressure falls below a predetermined

level. The pump is actuated by an oil pressure

switch which actuates a solenoid which in turn

starts the pump if engine oil pressure falls below 4

psi (0,3 bar).

A

B

2

1

4

3

5

MA0871