SkyTrak 6036 Service Manual User Manual

Page 197

Section 10.

Electrical System

Model 6036 S/N 9B0499 and Before

10-4

10.2.2

Backup Alarm

and Reverse Switch

A backup alarm sounds when the forward-neutral-

reverse travel select lever is in reverse. The alarm

is located above the air cleaner in the engine

compartment. It is energized by a reverse switch

that is mounted on the transmission shifter under

the left front console panel .

a.

Backup Alarm Removal

1.

Disconnect negative (–) cable (2, Fig. 10.38)

from the batteries.

2.

Disconnect alarm wiring.

3.

While supporting the backup alarm, remove

two bolts (5, Fig. 10.3) and lock washers (6).

4.

Lift backup alarm (10) from forklift.

b. Backup Alarm Disassembly

Do not disassemble the backup alarm.

c.

Backup Alarm Cleaning and Drying

Without submerging the backup alarm, clean the

alarm using an approved solvent and dry with a

lint-free cloth.

d. Backup Alarm Inspection and Replacement

1.

Test backup alarm by using short heavy

gauge wires connected to a fused or pro-

tected 6 A minimum output, 12 Vdc power

supply.

2.

Replace backup alarm if it malfunctions.

e.

Backup Alarm Installation

1.

While positioning backup alarm on mounting

plate, secure alarm to plate using two lock

washers (6) and two capscrews (5).

2.

Connect alarm wiring.

3.

Connect negative (–) cable to the batteries.

4.

Test backup alarm.

f.

Reverse Switch

Please refer to paragraph 10.7.6 for reverse

switch instructions.

10.2.3

Park Lock Warning Light

The park lock warning light, Fig. 10.43, illuminates

when the park lock switch is in the UP or FOR-

WARD position.

a.

Bulb Replacement

You will find the number of the bulb in the Electri-

cal Specifications Table at the end of this section.

To replace the bulb within the warning light,

remove the lower panel (7, Fig. 10.40) which is

secured by four capscrews (6). To gain access to

the bulb, pull straight downward on the lower part

of the park lock warning light.

b. Light Removal

To replace the park lock warning light, continue as

follows:

1.

Disconnect negative (–) cable (2, Fig. 10.38)

from the batteries.

2.

Remove the lower panel (7, Fig. 10.40) which

is secured by four capscrews (6). Disconnect

the wiring to the light.

3.

Remove the nut and locknut and lift the light

from the console.

c.

Light Installation

1.

Position the light in the console and install

locknut and nut.

2.

Connect wiring to light.

3.

Connect negative (–) cable to the batteries.

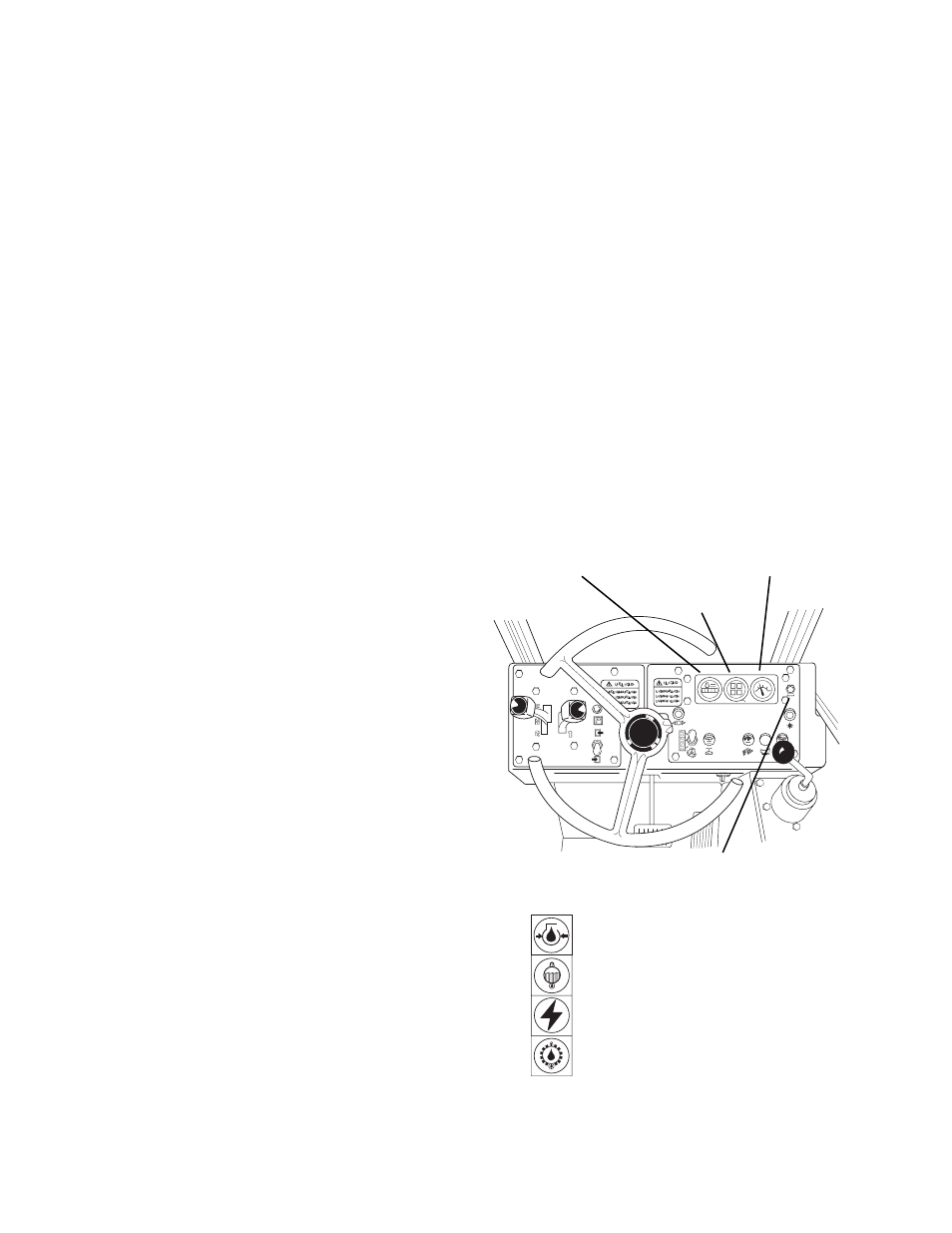

Fig. 10.4 Warning Lights Signal Dangerous

Operating Conditions

HOURMETER

FUEL GAUGE

Engine Oil Pressure—Indicates low

engine oil pressure.

Engine Water Temperature—

Indicates high coolant temperature.

Alternator Charging—Indicates

alternator is not charging.

Transmission Oil Temperature—

Indicates high transmission Oil

Temperature.

OA0031

WARNING

LIGHTS

BULB

TEST

BUTTON

OA0750