Warning – SkyTrak 6036 Service Manual User Manual

Page 137

Section 9.

Hydraulic System

Model 6036 S/N 9B0499 and Before

9-24

Warning !

IMPORTANT: Do not attempt to reset the boom

hoist cylinder counterbalance valves. If replace-

ment is necessary, replace both left and right hoist

cylinder cartridges at the same time with new

ones.

5.

Using a pin spanner wrench, unscrew the

gland (14) from the tube.

IMPORTANT: Protect the finish on the rod at

all times. Damage to the surface of the rod can

cause premature seal failure.

6.

Pull the rod (17) and attached parts straight

out of the tube.

IMPORTANT: When sliding the rod and piston

assembly in the tube, be careful so that gland

threads in the tube do not damage the piston (9).

Keep the rod in line with the tube barrel to prevent

binding.

7.

Remove the piston seal (10) from the piston.

8.

Fasten the eye end of the rod (17) in a soft-

jawed vise and put a padded support below

the rod near the piston to prevent damage to

the rod.

NOTE: It may be necessary to apply heat to break

the bond of the sealant between nut (8) and rod

(17) before the piston can be removed. Refer to

paragraph 9.2a.

9.

Remove the nut (8), piston (9), and gland (14)

from the rod.

10. Remove the O-ring (11) from the inside of the

piston.

Wait for the hydraulic fluid to cool before servic-

ing any hydraulic component. Hot hydraulic fluid

can cause severe burns.

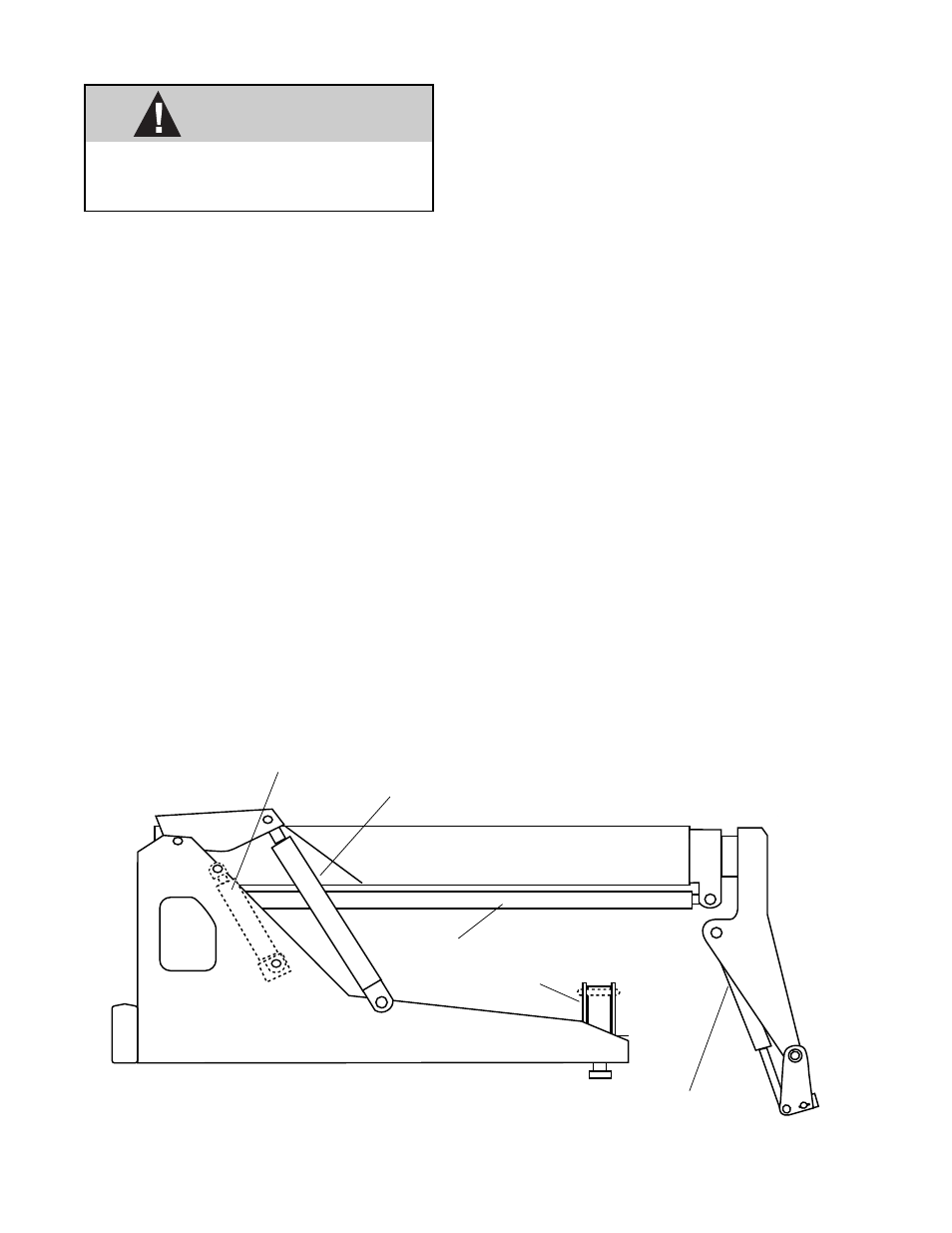

SLAVE CYLINDER

HOIST CYLINDER

OPTIONAL SIDE TILT CARRIAGE CYLINDER

IS SHOWN IN FIGURE 9.20

EXTEND CYLINDER

FRAME TILT CYLINDER

GRILLE TILT CYLINDER

Fig. 9.9 Hydraulic Cylinders

MA0501

5.

Remove pin and its locking capscrew and lock

nut securing the boom hoist cylinder rod to the

outer boom.

6.

Start the engine and fully retract cylinder.

7.

Disconnect the hydraulic lines from the

cylinder and cap or plug the open connections.

8.

Remove the pin and snap rings securing the

boom hoist cylinder to the frame.

9.

Remove the cylinder from the forklift using a

strap sling and hoist or other suitable lifting

equipment.

b. Disassembly of Boom Hoist Cylinder

with "TJB" Stamping

1.

Remove all dirt and grease from the cylinder.

2.

Fasten the cylinder in a soft-jawed vise or

other acceptable holding equipment. Do not

damage the tube.

3.

If necessary to replace, remove the grease

fittings (5, Fig. 9.10) and plugs (4 and 6).

4.

Remove the counterbalance valve (1) with O-

rings (2) and backup rings (3) from the tube

(7).