SkyTrak 6036 Service Manual User Manual

Page 209

Section 10.

Electrical System

Model 6036 S/N 9B0499 and Before

10-15

relative to the flywheel. When the teeth become

aligned, spring pressure slides the pinion into

mesh with the flywheel.

When the pinion is properly engaged with the

flywheel teeth a pair of contacts are closed in the

rear of the unit. Closure of the contacts connects

the motor to the battery, the armature rotates and

the starter pinion cranks the engine.

When the engine fires, the operator returns the

ignition key to the run position, the solenoid unit is

de-energized and the spring-loaded plunger in the

solenoid withdraws the starter pinion to its out-of-

mesh position. The armature (9) is brought rapidly

to rest by the centrifugal action of a pair of spring-

loaded brake shoes (16) bearing against a brake

drum inside the intermediate bracket (7).

If the pinion jams in mesh (this may occur with an

engine which fails to start) there is sufficient slack

in the engagement lever-to-solenoid plunger

linkage to permit the solenoid switch contacts to

open.

If the drive remains in mesh with the flywheel after

the engine has run up to speed, the starter motor

armature is protected from over speeding by the

plate clutch assembly. This clutch allows torque to

be transmitted from the starter motor to the engine

but not from the engine to the starter motor.

The clutch is set to slip at between two and three

times normal starting torque, thus providing

overload protection for the starter motor.

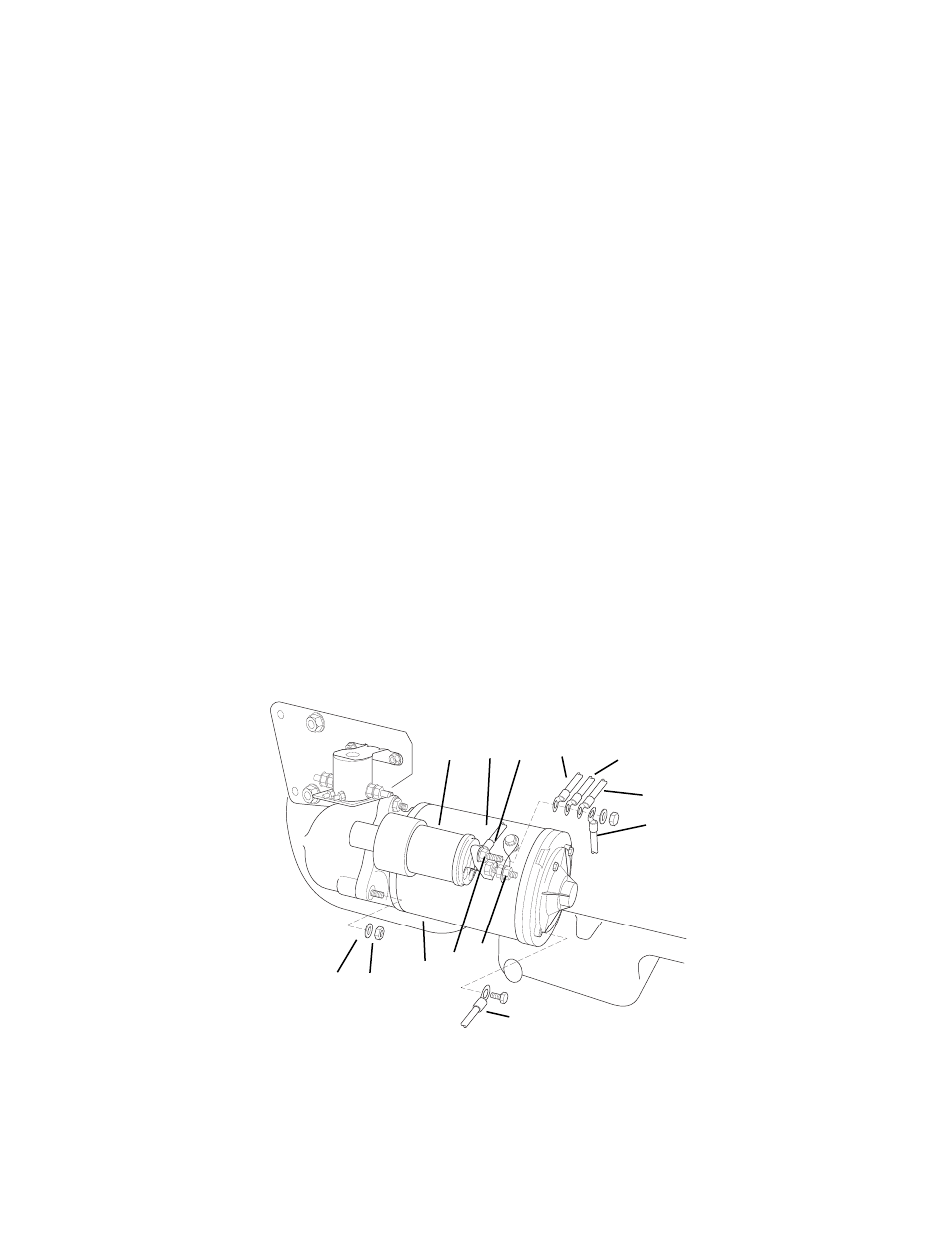

b. Removal

Remove the starter only if it fails the tests listed in

paragraph 10.5.2. To remove the starter:

1.

Disconnect negative (–) cable (2, Fig. 10.38)

from the batteries.

2.

Tag and disconnect the negative ground cable

(1, Fig. 10.15) from the starter.

3.

Tag and disconnect the positive cable (2) and

other wiring (3, 4, 5 and 6) from the starter

solenoid (7), paying attention to the sequence

in which the wires are installed on the termi-

nal.

4.

Loosen but do not remove the three hex nuts

(8) that secure the starter to the flywheel

housing. Be careful when you remove the

nuts because the starter is heavy and it will fall

if not supported. Using one hand to support

the starter, remove the nuts (8) and lock

washers (9) and lift the starter (10) from the

forklift.

c.

Disassembly

Disassemble starter only as required by the

periodic maintenance recommendations in para-

graph h.

d. Cleaning and Drying

1.

While the starter is out wipe away any grease

or dirt that has accumulated around the starter

hole.

Fig. 10.15 Starter Removal

5.

Wire 5

6.

Wire 19

7.

Starter solenoid

8.

Hex nuts

9.

Lock washers

1.

Starter negative ground cable

2.

Positive cable

3.

Wire 29

4.

Wire 27

10. Starter

11. Battery terminal

12. Starter motor terminal

13. Ignition switch terminal

1

6

7

8

9

10

11

12

5

13

2

3

4

MA0981