SkyTrak 6036 Service Manual User Manual

Page 164

9-51

Model 6036 S/N 9B0499 and Before

Section 9.

Hydraulic System

5.

Tag and disconnect three hydraulic hoses (4,

Fig. 9.30) from the right side of the service

brake valve. Cap and plug the open hose

connectors.

6.

Remove jam nuts (4, Fig. 9.28), lock washers

(5) and capscrews (6) which secure valve to

the mounting bracket.

7.

Remove the service brake valve from the

machine.

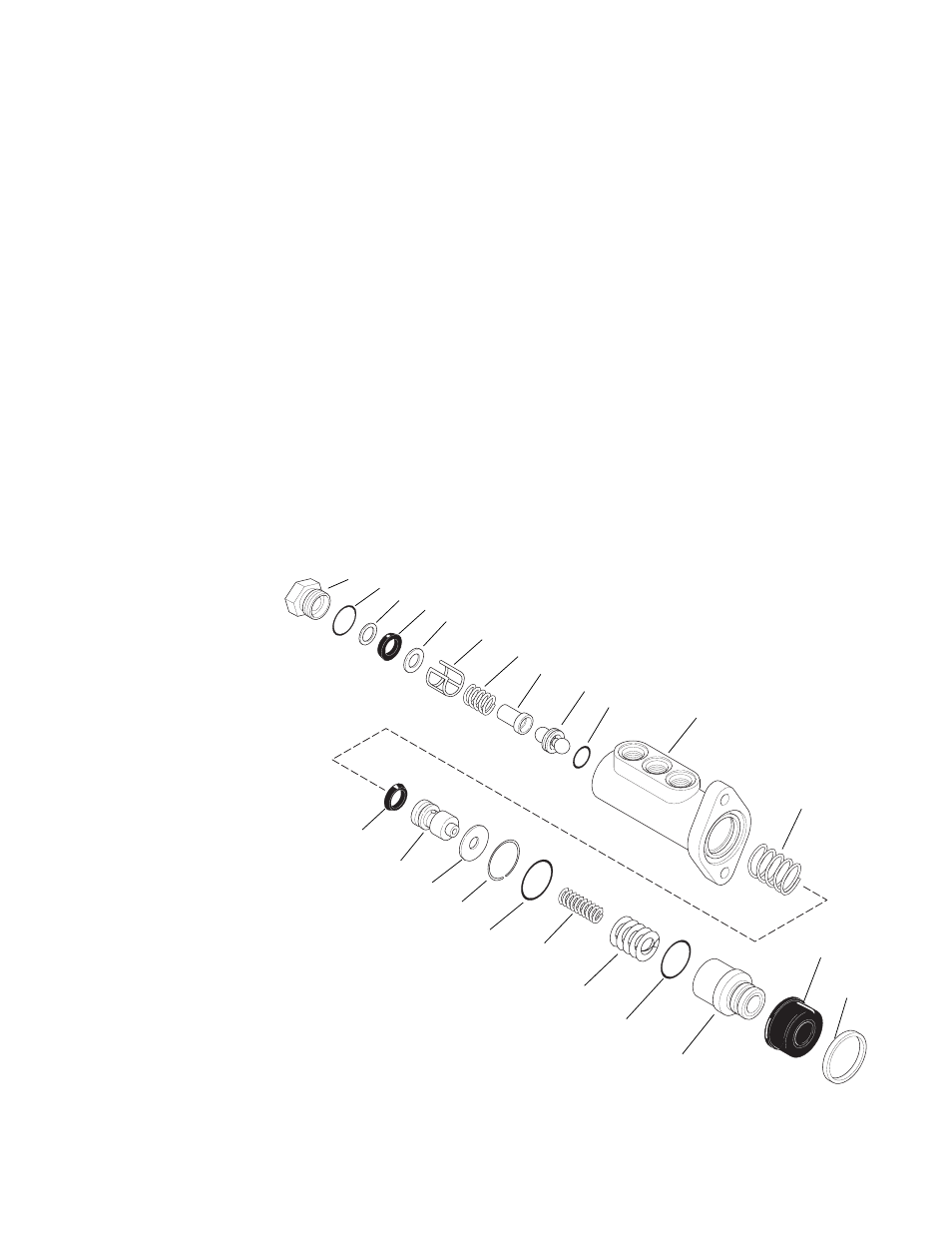

b. Disassembly

1.

Remove ring (1, Fig. 9.29) and boot (2) from

housing (13).

2.

Remove piston (3), shim or shims (4), and

springs (5 and 6) from housing bore.

3.

Carefully remove O-ring (7) to avoid scratch-

ing the housing bore.

4.

Carefully remove retaining ring (8) to avoid

scratching housing bore.

5.

Remove washer (9), plunger (10) and spring

(12) from housing bore.

1.

Retaining Ring

2.

Boot

3.

Piston

4.

Shims (as required)

5.

Spring

6.

Spring

7.

O-ring

8.

Retaining Ring

9.

Washer

10. Plunger

11. Cup

12. Spring

13. Housing

14. O-ring

15. Valve and Ball Assembly

16. Guide

17. Spring

18. Sleeve

19. Washer

20. Cup

21. Backup Ring

22. O-ring

23. Plug

Fig. 9.29 Brake Valve Exploded View

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

MA0701

6.

Remove cup (11) from plunger (10).

7.

Remove plug (23) from housing (13).

8.

Remove O-ring (22), cup (20) and backup ring

(21) from plug (23).

9.

Remove washer (19), sleeve (18), spring (17)

and guide (16) from the housing bore.

NOTE: Some valves may not have a sleeve (18).

10. Remove valve and ball assembly (15) from

housing bore.

11. Remove O-ring (14) from the valve and ball

assembly.

c.

Cleaning and Drying

Clean all metal parts in an approved cleaning

solvent such as trichlorethylene and blow dry.

d. Inspection, Repair and Replacement

1.

Inspect valve bore for deep grooves or other

damage. If there is any damage to the bore,

replace the entire brake valve.