SkyTrak 6036 Service Manual User Manual

Page 239

Section 10.

Electrical System

Model 6036 S/N 9B0499 and Before

10-45

d. Inspection and Replacement

Test the sender by suspending its probe in hy-

draulic fluid which is at least 10 °F (5 °C) below

250 °F (99 °C). The sender should remain open.

Increase the temperature of the fluid until it

exceeds this temperature by 10 °F (5 °C). The

sender should close.

e.

Installation

1.

Install the transmission high temperature

sender.

2.

Connect wire to terminal of transmission high

temperature sender.

3.

Connect negative (–) cable (2, Fig. 10.38) to

batteries.

4.

Operate engine and check transmission for

fluid leaks.

5.

Install transmission cover.

10.8.9

Fuel Gauge

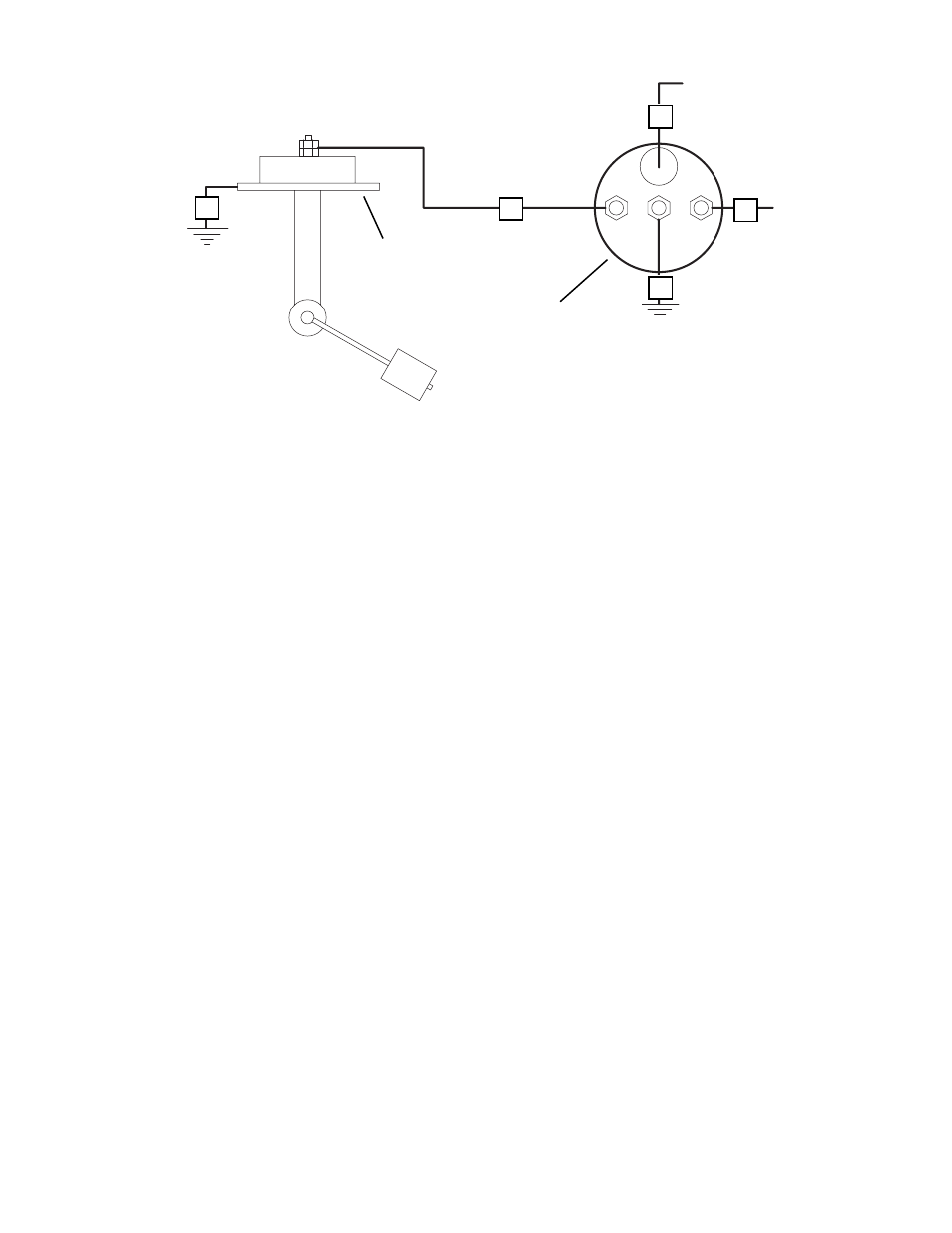

The fuel gauge indicates the liquid level in the fuel

tank. It consists of a resistance, float type fuel

level sender, Fig. 10.51, mounted in the top of the

fuel tank and a fuel level gauge in the control

console. The resistance range of the submerged

coil type fuel sender is 0-30 ohms.

The pointer of the fuel gauge is moved by the

magnetic field of two coils. The coils are at right

angles to each other. Battery voltage is applied to

the “E” coil and the circuit divides at the opposite

end of this coil. One path continues to ground

through the “F” coil. Another goes to ground

through the variable resistor of the fuel level

sender.

Fig. 10.51 Fuel Lever Sender and Fuel Gauge Schematic

When the tank is low, the resistance of the sender

is low. A large flow of current passes through the

“E” coil and the fuel level sender resistor. This

moves the pointer toward “E” on the scale. When

the tank is full the sender resistance is high. More

current flows through the “F” coil, moving the

pointer toward “F” on the scale.

With two coils operating the pointer, the gauge is

not affected by changes in the voltage of the

system.

a.

Fuel Gauge Testing

1.

With five gallons of fuel in the fuel tank, fuel

gauge needle must be at approximately 1/4

full.

2.

Use a jumper wire to jump across the two

wires at the fuel level sender on the fuel tank.

Fuel gauge needle must be at FULL mark.

3.

Switch ignition key OFF; needle must drop

below EMPTY.

If a fuel gauge malfunctions, perform the following

checks:

1.

Check for loose gauge mounting screws,

defective wiring, faulty grounds, and corrosion

on fuel tank ground connection.

2

If pointer in gauge does not move when

ignition key is turned ON, use a test lamp to

see if current is flowing from the ignition switch

to the terminal on the gauge. Also, be sure

paint or corrosion doesn’t prevent proper

ground. If pointer still doesn’t move, gauge is

defective and must be replaced.

3.

If gauge doesn’t indicate fuel level in tank, be

sure gauge is 0-30 ohm, 12 V.

17

29

12

2

FUEL LEVEL

SENDER

21

HYDRAULIC

PUMP CASE

GROUND

S

G

I

BACK SIDE OF FUEL

GAUGE

TO LIGHTING SYSTEM

FOR OPTIONAL FUEL

GAUGE LIGHT

MA1312