Warning, 3 axle lubrication – SkyTrak 6036 Service Manual User Manual

Page 71

Section 5.

Wheel Assembly, Tires, and Axle

Model 6036 S/N 9B0499 and Before

5-26

• Do not attempt carrier and differential removal

and installation and differential and pinion

disassembly and assembly without thor-

oughly understanding instructions in Spicer

®

Dana publications and correspondence which

applies to your forklift.

• If it becomes necessary to disassemble any

parts inside the carrier, it is suggested that

the entire axle be removed from the forklift

and held tight in a stand or rack with carrier

pinion positioned up.

• When removing axle assembly, make sure

forklift is properly supported; an improperly

supported vehicle can cause serious injury or

death.

• If axle assembly is still in the forklift, be sure

carrier, differential and pinion assemblies are

securely supported before they are separated

from the axle housing.

Warning !

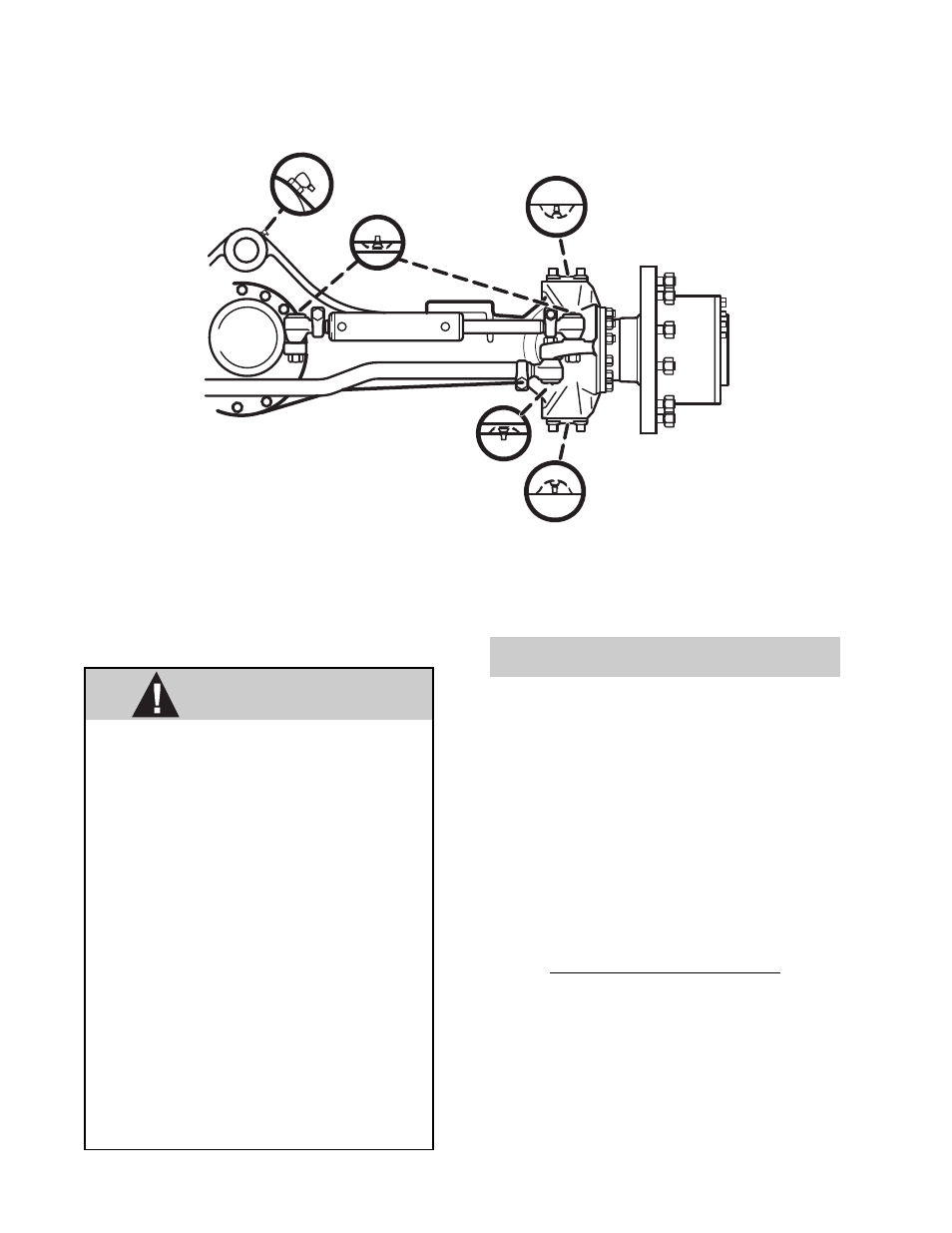

Fig. 5.17 Axle Grease Points

5.3

AXLE LUBRICATION

5.3.1 Grease

Lubricate the following axle points (Fig. 5.17) after

overhaul or at 50 hour intervals using multi-purpose

lithium-based grease:

• pivot pins (4 points)

Lubricate the following axle points (Fig. 5.17) after

overhaul or at 250 hour intervals using multi-

purpose lithium-based grease:

• steering knuckles (8 points)

• tie rod ball joints (4 points)

• steer cylinder ball joints (8 points )

5.3.2 Differential Housing Oil

Level Check (250 hour intervals)

1.

Clean the area around the axle and remove the

fill and level plug (Fig. 5.18) from the axle

housing.

2.

Check the oil level.

3.

Add gear oil meeting military specification MIL-

L2105C API classification GL-5 to the level of

the plug hole. The oil should be a 90W or

multi-grade 80W-90 with EP properties.

STEER CYLINDER

BALL JOINT

PIVOT PIN

KNUCKLE

KNUCKLE

TIE ROD

BALL JOINT

OA0192