SkyTrak 6036 Service Manual User Manual

Page 108

Section 8.

Engine

8-22

Model 6036 S/N 9B0499 and Before

13. Secure transmission drive shaft to transmis-

sion with U-bolt or bearing strap. Torque U-bolt

to 20 to 24 lb-ft (27 to 37 N m) or bearing strap

to 55 to 60 lb-ft (75 to 82 N m).

14. Install the transmission control cables as

follows:

(a) Place the transmission control valve

spools, Fig. 4.4, in the center position.

(b) Secure the control cables to the bracket

being sure to have the clamp and cable

grooves aligned.

(c) Position swivel and lock nut on rod end as

shown in Fig. 4.4. Tighten the locknut.

(d) Be sure the shifter levers are in the center

or middle position.

(e) Reposition the swivel and lock nut so it

aligns with its hole in the swivel linkage

control arm.

(f) Secure the swivel to the control arm with

cotter pin.

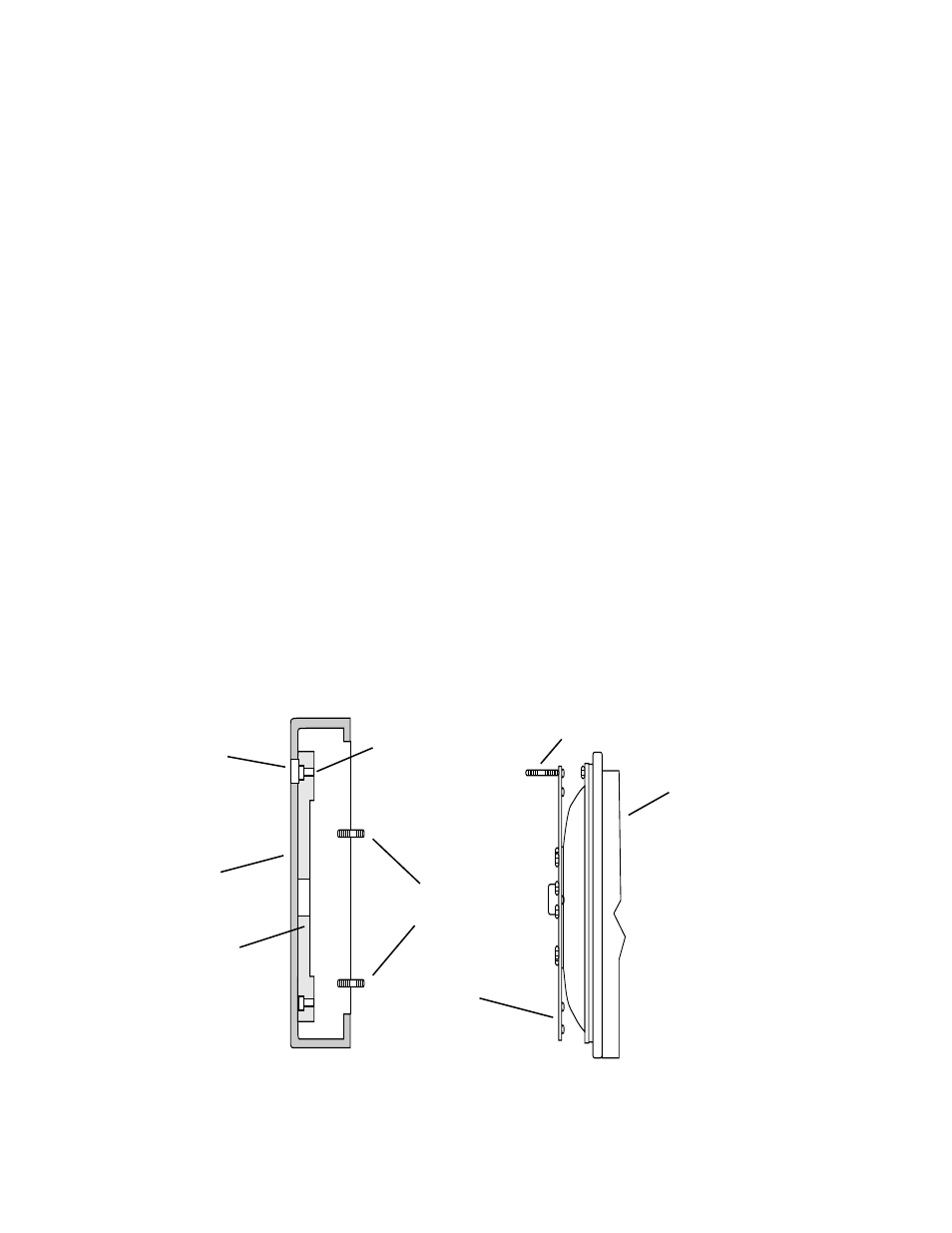

2-1/2" GUIDE

STUDS

FLYWHEEL

DRIVE PLATE

FLYWHEEL

HOUSING

CONVERTER

HOUSING

ACCESS HOLE

4" LOCATING

STUD

DRIVE PLATE

MOUNTING

SCREW HOLE

10. After all eight capscrews have been installed,

rotate the engine flywheel again and individually

torque all eight to 25 to 30 lb-ft (34 to 40,8 N m).

11. Install the engine and transmission on the

forklift frame as follows:

(a) Attach a suitable engine hoist to the lifting

lugs on the top of the engine.

(b) Push the engine and transmission in

through the rear of the forklift and rest it on

the frame aligning the engine mount hole.

(c) Secure both transmission mounts to the

transmission and frame with capscrews

and locknuts.

•

Torque the 1/2-inch capscrew attaching the

mount to the frame to 68 to 72 lb-ft (93 to 98

N m).

•

Torque the 3/4-inch capscrews attaching the

mount to the transmission to 225 to 275 lb-ft

(306 to 374 N m).

(d) Secure the engine mount to the frame with

a capscrew, vibration mount, rebound

washer, and locknut. Torque to 225 to 275

lb-ft (306 to 374 N m).

(e) Remove the engine hoist.

12. Attach the main pump to the transmission.

Fig. 8.28 Locating Stud

MA0401