SkyTrak 6036 Service Manual User Manual

Page 217

Section 10.

Electrical System

Model 6036 S/N 9B0499 and Before

10-23

If indicator lamp operates normally, proceed to "B.

ABNORMAL CHARGING SYSTEM OPERATION.”

Otherwise, proceed to either one of the following

three abnormal conditions.

1.

Switch Off, Lamp On. In this case, disconnect

the two leads from the alternator No. 1 and

No. 2 terminals. If the lamp stays on, there is

a short between these two leads. If the lamp

goes out, replace the rectifier bridge as

covered in paragraph 10.6.1.g. This condition

will cause an undercharged battery.

2.

Switch On, Lamp Off, Engine Stopped. This

condition can be caused by the defects listed

in step 1 above, or by an open wire in the

circuit. To determine where an open exists,

proceed as follows:

(a) Check for an open circuit breaker, a

burned out bulb, defective bulb socket, or

an open in No. 1 lead circuit between

alternator and ignition switch.

(b) If no defects have been found, proceed to

“B. ABNORMAL CHARGING SYSTEM

OPERATION.”

OFF

OFF

STOPPED

ON

ON

STOPPED

ON

OFF

RUNNING

Ignition Switch

Lamp

Engine

The other method follows:

A basic wiring diagram showing lead connections

is shown in Fig. 10.26. To avoid damage to the

electrical equipment, always observe the following

precautions:

• Do not polarize the alternator.

• Do not short across or ground any of the

terminals in the charging circuit, except as

specifically instructed herein.

• Make sure the alternator and batteries

have the same ground polarity.

• When connecting a charger or a booster

battery to the forklift batteries, connect

negative to negative and positive to

positive. The correct jump start procedure

is covered in paragraph 10.6.2.g.

Trouble in the charging system will show up as

one or more of the following conditions:

A. Abnormal indicator lamp operation.

B. Abnormal charging system operation.

A. Abnormal Indicator Lamp Operation.

Check the indicator lamp on the control console

for normal operation as shown below:

3.

Switch On, Lamp On, Engine Running. Check

for an open circuit breaker between indicator

lamp and switch. Other possibilities are

covered in “B. ABNORMAL CHARGING

SYSTEM OPERATION”.

If a defect has been found and corrected at this

point, no further checks need be made.

B. Abnormal Charging System Operation

1.

Check that discharged batteries weren’t

caused by accessories left ON for extended

periods.

2.

Check alternator drive belt for proper slack

adjustment.

3.

If a battery defect is suspected, refer to

Section 10.6.2 Battery.

4.

Inspect the wiring for defects. Check all

connections for tightness and cleanliness,

including the slip connectors at the alternator

and connections at the batteries.

5.

With ignition switch ON and all wiring harness

leads connected, connect a voltmeter from:

(a) Alternator BAT TERMINAL to ground.

(b) Alternator NO. 1 TERMINAL to ground.

(c) Alternator NO. 2 TERMINAL to ground.

A zero reading indicates an open between voltme-

ter connection and batteries. Repair wiring

harness if required.

6.

With all accessories turned off, connect a

voltmeter across the batteries. Operate

engine at moderate speed. If voltage is 15.5 V

or more on a 12 V system, remove alternator

for repair.

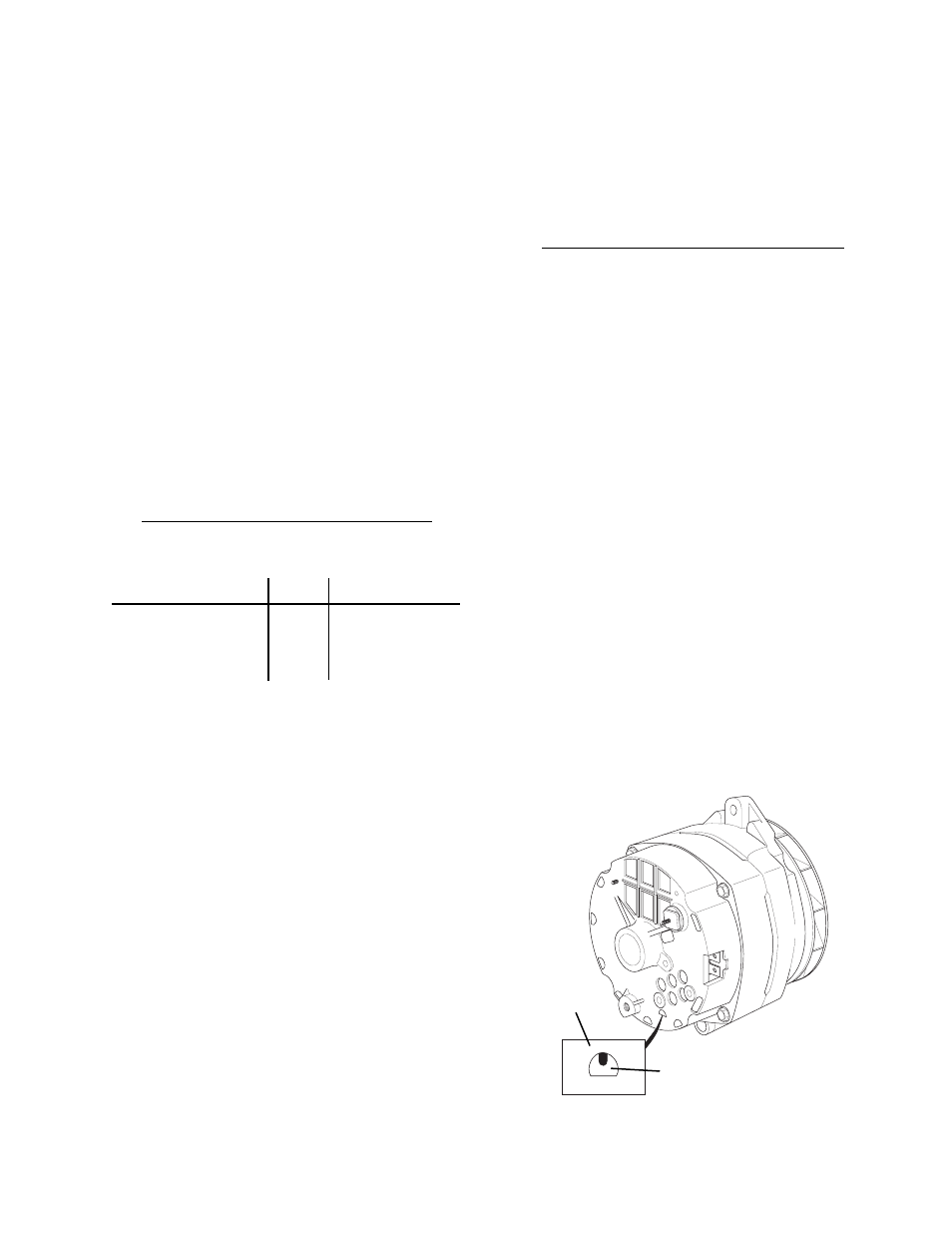

Fig. 10.27 Grounding Alternator Field Winding

(Wiring Connections Are Not Shown)

TAB

INSERT SCREWDRIVER IN

THIS HOLE TO GROUND

TAB TO END FRAME

MA1101