Hardware settings, Dynaflow, User manual - maintenance – Ransburg DynaFlow User Manual User Manual

Page 79: Channel module settings

LN-9400-00.9

75

DynaFlow

TM

User Manual - Maintenance

HARDWARE SETTINGS

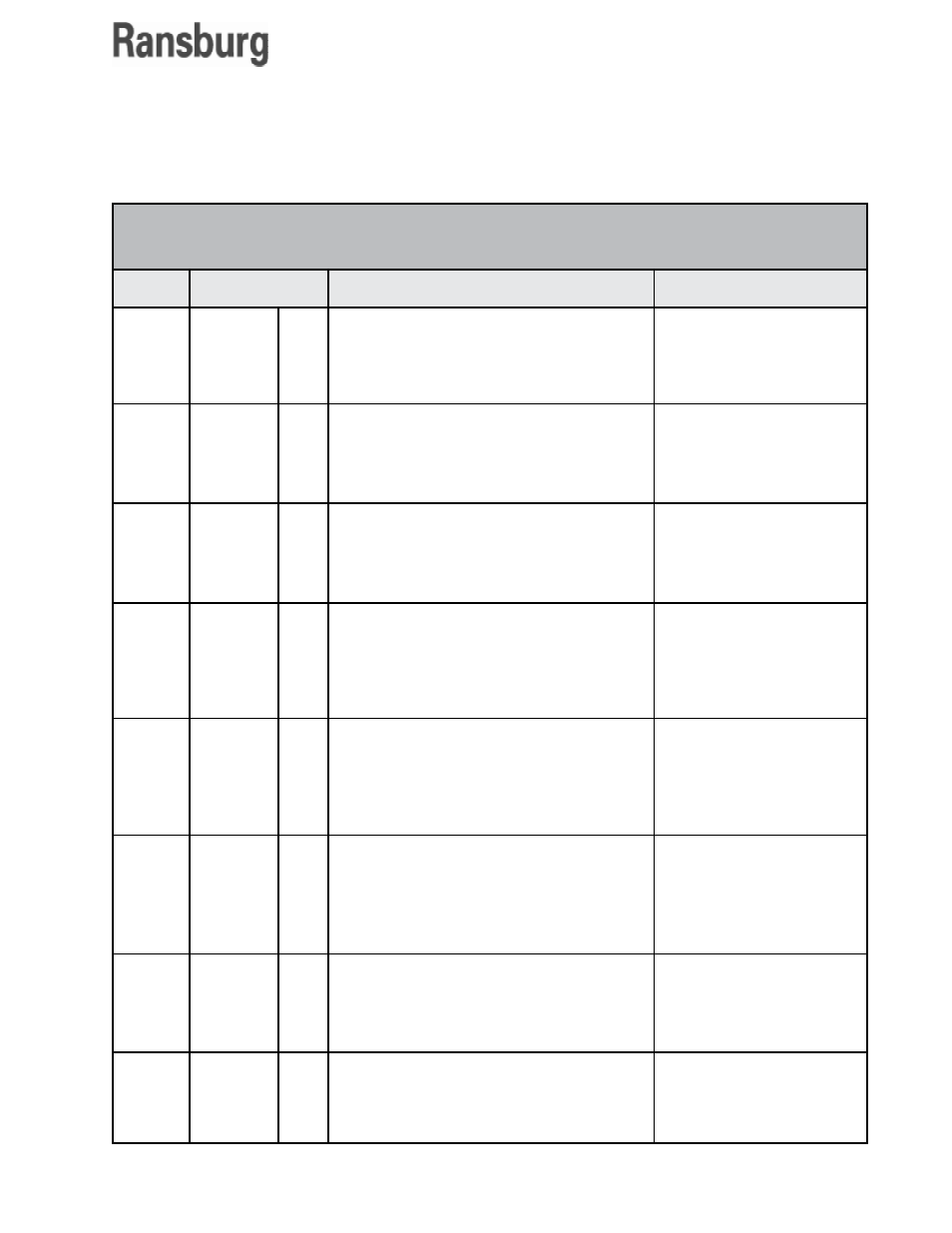

Channel Module Settings

Jumper

Description

Comments

E1

E5

E6

E8

E10

E9

E4

E3

ROM size select.

1-2 = 256K, 27256 device

2-3 = 512K or 1024K, 27512 or

27010 devices

Selects 0-10 VDC or 4-20 ma operation for

the analog control output #1.

2-3 = 0-10 VDC

1-2 = 4-20 mA

Selects 0-10 VDC or 4-20 ma operation for

the spare analog output #1.

2-3 = 0-10 VDC

1-2 = 4-20 mA

Selects 24 VDC source control or grounded

sink control for digital inputs 8-11.

2-3 = 24 VDC source

1-2 = grounded sink

Selects 24 VDC source control or grounded

sink control for digital inputs 4-7.

2-3 = 24 VDC source

1-2 = grounded sink

Selects 24 VDC source control or grounded

sink control for digital inputs 0-3.

2-3 = 24 VDC source

1-2 = grounded sink

Selects 0-10 VDC or 4-20 ma operation for

the analog set point input #1.

2-3 = 0-10 VDC

1-2 = 4-20 mA

Selects 0-10 VDC or 4-20 ma operation for

the spare analog input #1.

2-3 = 0-10 VDC

1-2 = 4-20 mA

Factory set. Do not change

unless instructed to do so.

To the E/P transducer #1

Actual flow rate for

CHANNEL #2, scaled by

Maximum and Minimum Flow

Rate parameters

Inputs effected:

Load Mode #1

Analog Hold #1

External Fault #1

MVR Enable #1

Inputs effected:

Run #1

Halt #1

Total Reset #1

Clean #1

Inputs effected:

Trigger #1

Gun Mask #1

Transparent/PID #1

Total Hold #1

Scaled by Maximum and

Minimum Flow Rate

parameters

CHANNEL MODULE P/N: 77206-XX (Obsolete)

MOTHER BOARD JUMPER BOARD SETTINGS (CHANNEL 1 I/O)

Default Setting

512K

1024K

0-10 VDC

0-10 VDC

Source

Source

Source

0-10 VDC

0-10 VDC

2-3

2-3

2-3

2-3

2-3

2-3

2-3

2-3