Dynaflow, User manual - maintenance gun flow out of range, Out of tolerance faults – Ransburg DynaFlow User Manual User Manual

Page 73: Gun not ready, Analog sealing

LN-9400-00.9

69

DynaFlow

TM

User Manual - Maintenance

Gun Flow Out of Range

Explanation: (Manual Guns Only) This fault in-

dicates that the total flow rate through a GUN

has exceeded the MAXIMUM FLOW RATE JOB

parameter value or dropped below the MINIMUM

FLOW RATE JOB parameter.

Out of Tolerance Faults

Explanation: "OUT OF TOLERANCE" faults are

generated in the following manner. Every time a

specific volume of fluid passes through the GUN

(specified by the TOLERANCE VOLUME param-

eter), the controller determines the amount of resin

and catalyst material that flowed. The controller

then calculates the actual ratio and determines if

it is within the limits as set by the FLOW TOLER-

ANCE setting.

Reference the "Error Codes" table (Figure 16).

Typical causes for OUT OF TOLERANCE faults

are:

1. Kp, Ki, or Kd gains not set correctly.

2. Sticking or faulty fluid regulator.

3. Sticking or faulty flow meter.

4. Running the wrong JOB #, which may in-

clude the wrong gain values.

5. Fluid supply pressures not adjusted properly.

6. The MVR LOW JOB parameter set too high

(above the regulator cracking pressure).

7. Air bubbles or cavitation in the fluid.

8. Unstable fluid supply pressures to the fluid

regulators. This can be seen with pump supply

systems.

Corrective Action:

The cause is the material supply pressure in almost

every case when this fault is observed. Obviously,

if FLOW TOO LOW or FLOW TOO HIGH faults are

not occurring, the flow rates are operating within

the range of the fluid regulators. Over an extended

period of time, however, the volumes used are not

within the appropriate tolerance band. Observe

the ratio for both the resin and catalyst channels

that are producing faults while they are operating

or immediately after the controller faults (before

resetting it). If the actual ratio of the catalyst is

below target, adjust the supply pressure to the

catalyst regulator up approximately 5 psi, or adjust

the resin supply down by approximately 5 psi and

try to run again. Keep adjusting these pressures

until the actual ratio locks in on the target. Keep

in mind that higher is not always better. Many

times it is better to lower the pressure of the op-

posite channel, rather than raise a channel that

is operating low in ratio.

The Kp and Ki gain settings located in the JOB

tables may also be used to eliminate OUT OF

TOLERANCE faults. For example, if an OUT OF

TOLERANCE - CATALYST TOO HIGH fault occurs,

adjust the gain settings for the catalyst channel

down and vice-versa for a OUT OF TOLERANCE

- CATALYST TOO LOW fault. The resin channel

also needs to be taken into account for GUNs

configured as automatic.

Gun Not Ready

Explanation: This is not a fault condition and does

not prevent the GUN from operating. This error

occurs if a GUN has not been configured, is not

enabled, or no JOB #s have yet been saved and

the GUN is placed in the RUN mode. This can be

caused by trying to place a GUN in RUN mode

either from local display/interface or from an ex-

ternal control device such as a PLC or host PC.

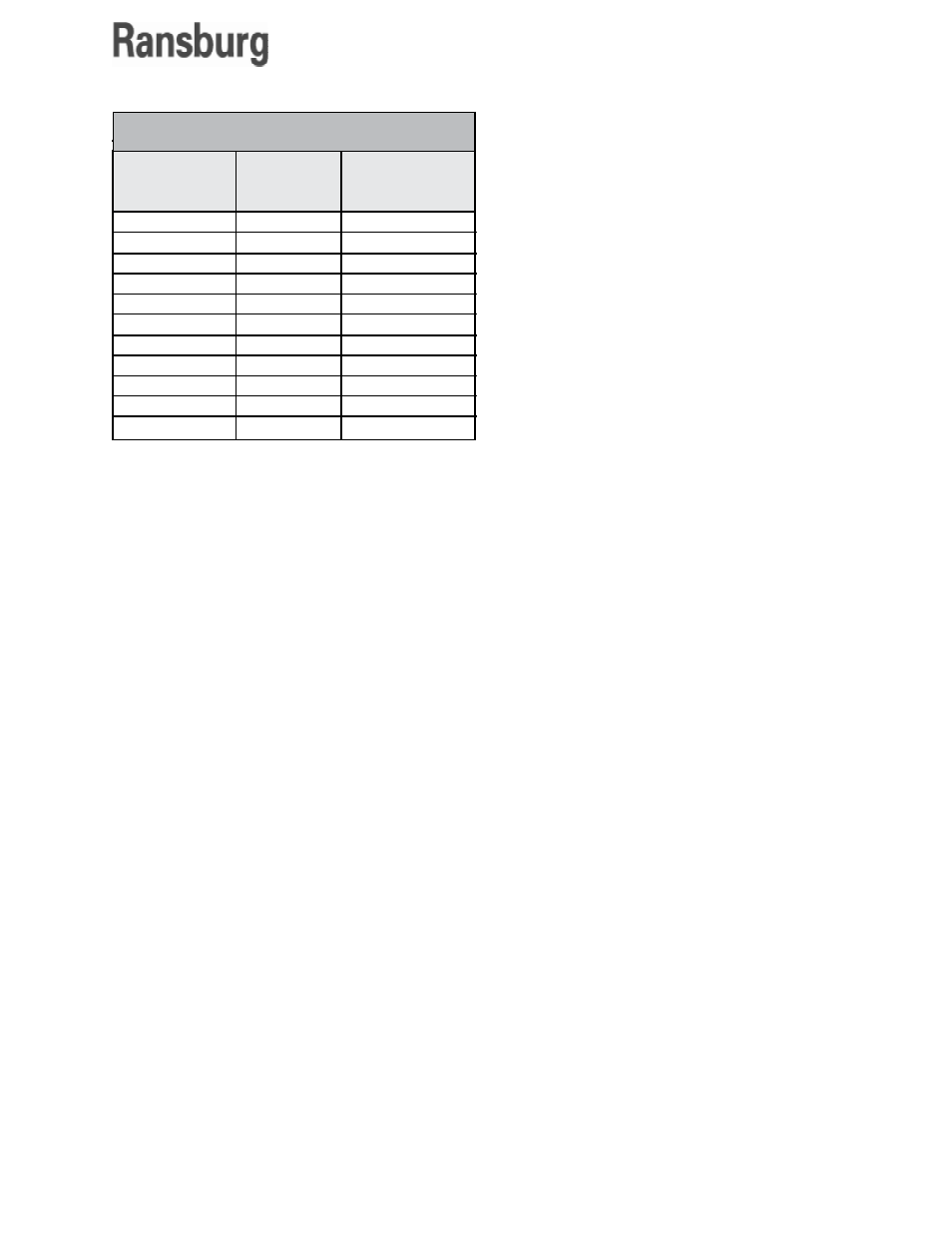

Control Output

0 - 10 VDC

0

1

2

3

4

5

6

7

8

9

10

4

5.6

7.2

8.8

10.4

12.0

13.6

15.2

16.8

18.4

20.0

4-20 mA

Pressure

(PSIG)

0

10

20

30

40

50

60

70

80

90

100

ANALOG SEALING