Dynaflow, User manual - maintenance, Error codes (cont.) – Ransburg DynaFlow User Manual User Manual

Page 67

LN-9400-00.9

DynaFlow

TM

User Manual - Maintenance

63

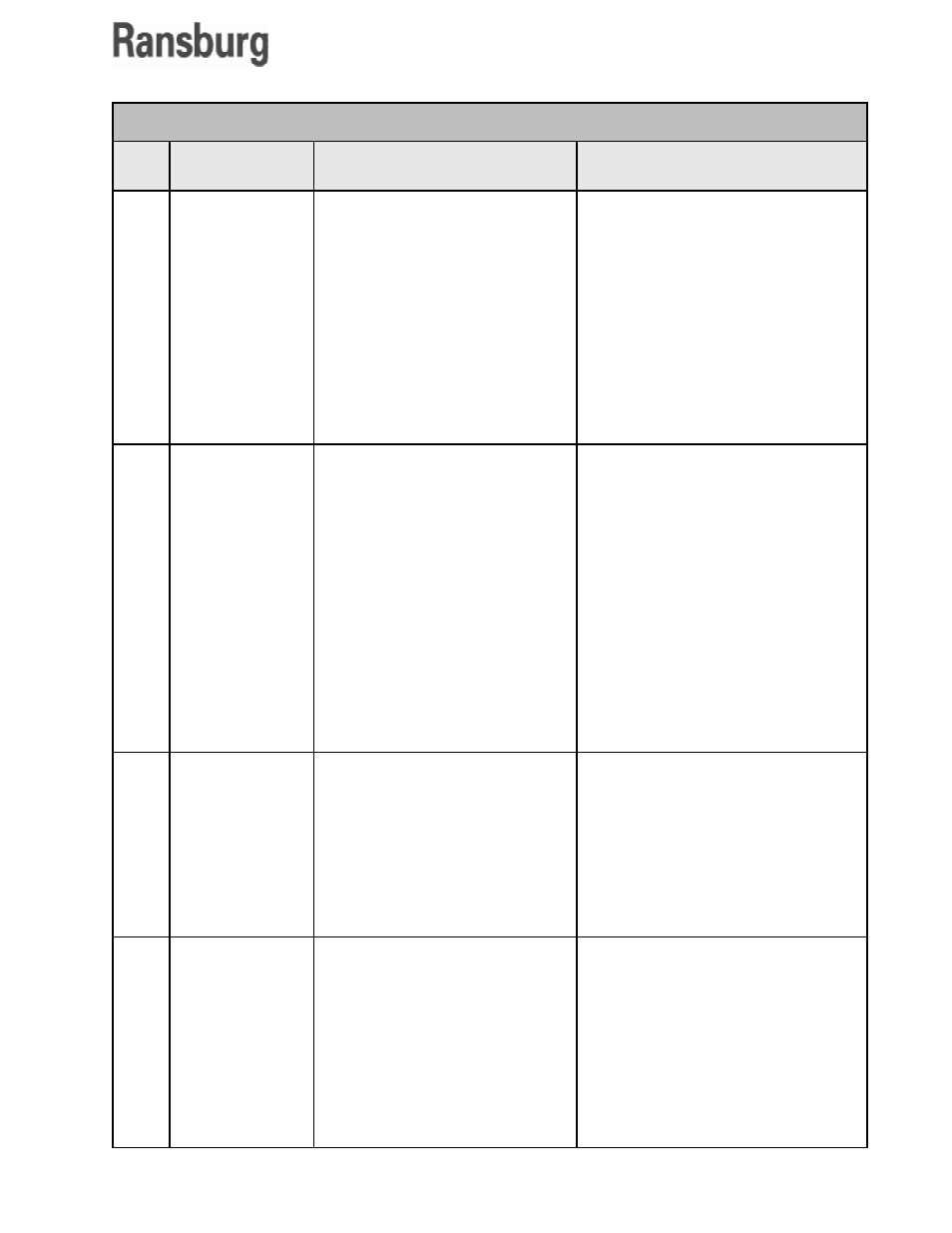

Displayed Text

Fault Cause

Corrective Action

Reverse Flow Limit

-

CHANNEL #<>

The amount of reverse flow for the

indicated CHANNEL has ex-ceeded

the maximum allowable amount as

defined in the CHANNEL parameter

set.

Last digit indicates

CHANNEL #.

Check the following:

1. That the Reverse Flow value entered

in the JOB # is correct.

2. Flow meter fiber-optic cables are

properly connected and not reversed.

3. Fluid pressures are properly set and

stable.

4. All check valves are operating cor-

rectly.

5. All fluid lines filled and all valves

open.

6. Flow meter is operating properly.

Code

9021

9022

9023

9024

9025

9026

9027

9028

9031

9032

9033

9034

9035

9036

9037

9038

Flow Too Low -

CHANNEL #<>

The flow rate for the indicated

CHANNEL # is too low. Based on

the transducer output. Not issued

for a manual GUN, master

CHANNEL.

Last digit indicates

CHANNEL #.

Check the following:

1. There is fluid in the fluid lines for the

indicated CHANNEL.

2. Fluid pressures are properly set and

stable.

3. The pilot air line to the fluid regulator

is not damaged or leaking.

4. Fluid viscosity is correct for the

CHANNEL pressure and pipe size.

5. The pressure transducer and regula-

tor are operating properly.

6. Transducer air supply is at least 90

psi.

7. Kp, Ki, and Kd Gains are set correctly

for the indicated CHANNEL.

9041

9042

9043

9044

9045

9046

9047

9048

Flow Too High

The flow rate for the indicated

CHANNEL # is too high. Based on

the transducer output. Not issued

for a manual GUN, master

CHANNEL.

Last digit indicates

CHANNEL #.

Check the following:

1. Fluid regulators - sticking or faulty.

2. Control parameters - gains possibly

set too high.

3. MVR low setting too high.

9071

9072

9073

9074

9075

9076

9077

9078

No Master Flow

Manual mode only. A trigger signal

was received and no fluid flow

was detected through the master

chan-nel after the Blowoff timer had

elapsed (if used).

Check the following:

1. There is fluid in the fluid lines for the

indicated CHANNEL.

2. Fluid pressure is OK.

3. The flow meter, pressure trans-ducer,

and regulator are operating properly.

ERROR CODES (Cont.)