Dynaflow, User manual - operation, Default control parameters – Ransburg DynaFlow User Manual User Manual

Page 62: Typical ranges for control parameters

LN-9400-00.9

DynaFlow

TM

User Manual - Operation

58

Recommended to start with these values and

confirm stable response before trying to achieve

faster response from the system. Generally,

when adjusting the Proportional (Kp) and Integral

(Ki) gain parameters, adjust both up or down pro-

portional to themselves. In other words, if faster

response is desired and the system is currently

operating stable, assume the starting Kp value is

500 and the starting Ki value is 2000. You would

adjust the Kp value to 550 (10% increase) and

the Ki value to 2200 (also a 10% increase). The

deadband parameter should be kept to 1 and the

differential gain (Kd) at 0.

Quick triggering applications: For applications

requiring multiple, short trigger cycles, more

stable response can typically be obtained by

adjusting the Kp down to approximately 75-100,

while adjusting the Ki to approximately 1000-2500.

2. The Integral gain is probably the most impor-

tant setting and has the greatest overall impact

on response behavior associated with the fluid

flow control system. This parameter can also be

adjusted through a relatively large range without

creating instability.

3. The Proportional gain can improve system

response, especially for large set point changes,

but care should be taken not to increase by more

than approximately 25% of the default setting. The

system can easily become unstable and go into

oscillation if adjusted to high.

4. The differential gain has the least effect on

system performance and should be left at the

default setting of zero (0).

5. Response times will be limited by changes in

the fluid mechanics of the system. It will take

longer to achieve requested flow rate as fluid

viscosity increases or fluid supply pressure de-

creases. In other words, the same response cannot

be achieved for a 50 sec, Zahn #2 material as for

a 20 sec, Zahn #2 material given the same fluid

supply pressure and fluid control components.

This is important to understand, especially for 2K

systems. It may be an advantage to purposely

slow down the response of the quicker reacting

(thinner) fluid such that it will remain closer to that

of the thicker fluid in 2K systems during triggers

or changes in the set point. Other options are to

decrease the supply pressure for the thinner fluid

or increase pressure for the thicker fluid.

6. "Reset Windup" condition. Reference "Trouble-

shooting" in the "Maintenance" section. Reset

windup is a condition when the controller does not

have enough strength to reduce the error back to

zero. This occurs due to unusual restrictions in

the fluid control devices or fluid lines and indicates

that the system is not tuned properly or there is

a problem. If the actual fluid flow is less than the

requested flow (minus the dead band value), the

controller will continue to increase the output until

it reaches the maximum allowable fluid regulator

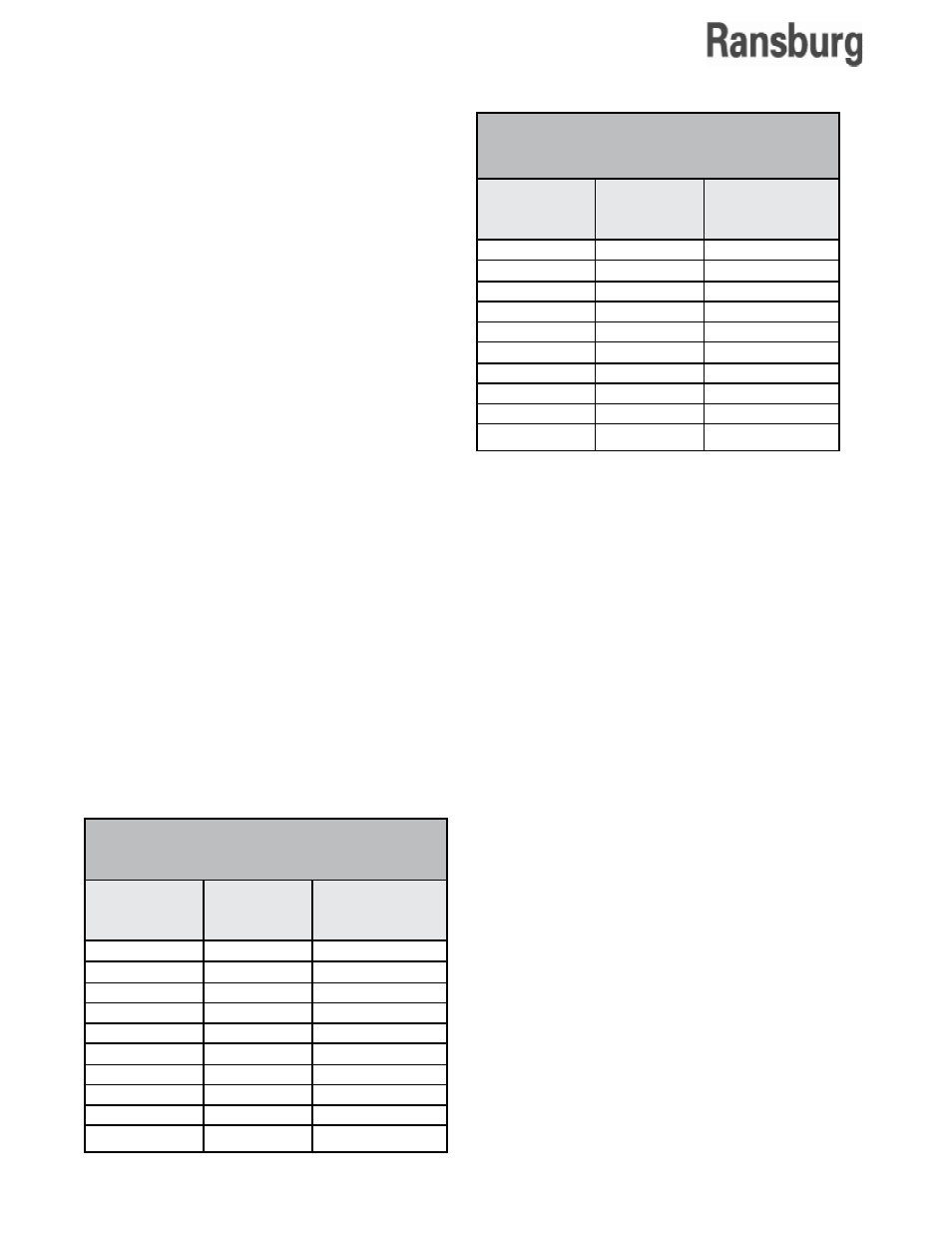

Fluid

Regulator

MVR #2

MVR #3

MVR #4

DR1, 1:1

DR1, 1:2

DR1, 1:3

DR1, 1:4

DR1, 1:6

DR1, 1:8

DR1, 1:10

10

15

20

50

45

40

35

30

25

20

Kp

Ki

1200

1000

800

1000

1200

1400

1600

1800

2000

2200

DEFAULT CONTROL

PARAMETERS

Fluid

Regulator

MVR #2

MVR #3

MVR #4

DR1, 1:1

DR1, 1:2

DR1, 1:3

DR1, 1:4

DR1, 1:6

DR1, 1:8

DR1, 1:10

0-500

0-500

0-500

0-500

0-500

0-500

0-500

0-500

0-500

0-500

Kp Typical

Range

Ki Typical

Range

600-2400

500-2000

400-1600

500-2000

600-2400

700-2800

800-3200

900-3600

1000-4000

1100-4400

TYPICAL RANGES FOR

CONTROL PARAMETERS