Gun inputs dynaflow, User manual - installation, Gun i/o – Ransburg DynaFlow User Manual User Manual

Page 25

LN-9400-00.9

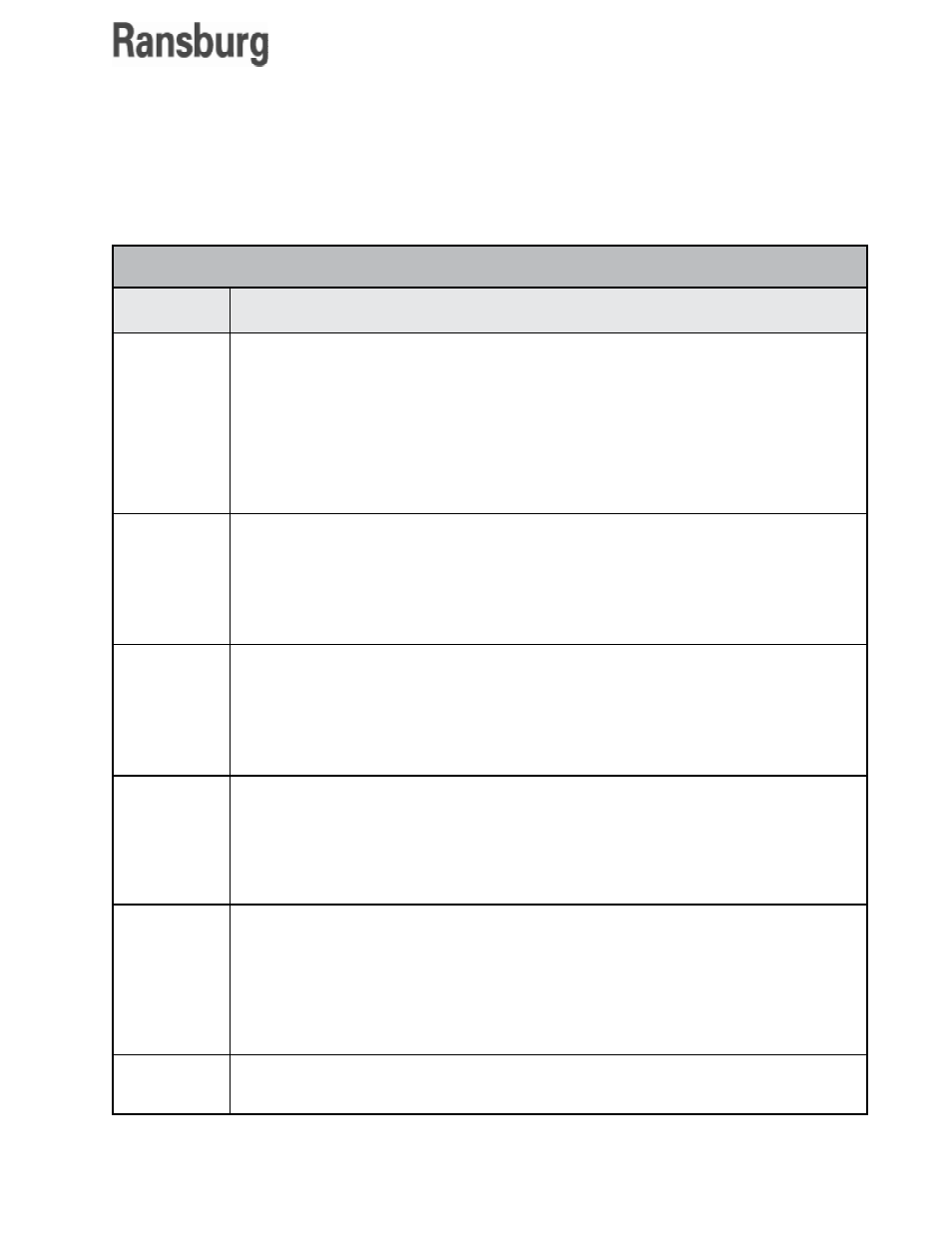

Discrete GUN I/O provides the input control and output status signals required to interface each GUN

with a PLC or similar controller, or other system control components. All GUN I/O can also be controlled

or monitored through an external host controller operating through a serial data communications link

or the state of each forced active through the local OPERATOR INTERFACE/host controller.

Description

Trigger

Halt/Reset

Clean

Run

Gun Mask

Total Reset

For automatic applicators: Starts fluid flow when supplied a 24 VDC signal assuming that the

GUN has been put in run mode, is configured properly, and all other conditions are satisfied.

For manual GUNs: A Trigger signal is required for the LOAD mode. The Trigger signal can

be generated from an atomizing air flow switch. If a Trigger signal is received from the flow

switch but no fluid flow is recorded from the catalyst (slaved) CHANNEL, then a FLOW TOO

LOW fault is generated. This ensures that both material components are present to the GUN.

If the dip switch, Pos #1 on the Channel Card is on, then this input is not used. Fluid flow

through the master channel is used to indicate a TRIGGER ON condition.

Halt requires a pulsed signal of at least 0.25 seconds duration. It is used to stop the JOB #

currently being executed or to stop a CLEAN/PURGE operation. GUN faults are also reset.

While in HALT mode, any new JOB # selection using the JOB # Strobe will be entered into

the Queue. The GUN will run the JOB # located in the Queue when a RUN signal is again

supplied. The faults can still be viewed in the ERROR LOG data table. Halt has no effect on

the JOB # in the Queue (Next JOB # to be run).

Clean requires a pulsed signal of at least 0.25 seconds duration. It forces the material regula-

tors controlled by the GUN parameters to the full open position. This permits the fluid system

to be cleaned. The removal of the GUN Enable signal or a HALT input signal is required to

end the CLEAN operation. Actual cleaning sequencing (PURGE) such as soft air push-out is

performed by the PLC, or other external controller. For details, refer to "Clean Mode" in the

"Operation" section of this manual.

This input will activate the GUN and will allow material flow if all other requirements are met.

This is identical to pushing the GUN ON switch on the OPERATOR INTERFACE PANELS.

Run requires a pulsed signal of at least 0.25 seconds duration. If this signal is reapplied once

the JOB # has been started, then it is ignored. When this signal is supplied following a HALT,

the JOB # stored in the queue will be activated. If no new JOB # was entered during the

previous HALT, then the JOB # located in the queue will not change and will be used again.

The Gun Mask input specifies whether a JOB # or toggled into GUN #n queue. This signal

is used in conjunction with the system PROGRAM SELECT and PROGRAM STROBE inputs.

A 24 VDC signal selects the GUN, a 0 VDC signal masks the GUN as ‘not used for the JOB

# selected’. Multiple gun masks can be asserted simultaneously if it is desired to load more

than one gun with the same JOB #.

Total Reset requires a pulsed signal of at least 0.25 seconds duration. This signal will reset

the daily and JOB totals for the GUN. The non-resettable total will not be effected.

GUN INPUTS

DynaFlow

TM

User Manual - Installation

21

Input

Signals

Gun I/O