Manual hand gun applications, Load mode, Dynaflow – Ransburg DynaFlow User Manual User Manual

Page 49: User manual - operation

LN-9400-00.9

RIO Set Point

The Total Flow Rate set point for a GUN may

also be input via Remote I/O (RIO). No scaling is

required, since the Total Flow Rate value is sent

in cc's/minute. RIO control is initiated when the

value sent is non-zero, regardless if an Analog

Input Set Point greater than 0.25 volts is presented

to the Master CHANNEL.

Analog Input Set Point

The Total Flow Rate set point for a GUN may be

input via an external analog signal (0-10 VDC or

4-20 ma) presented to the Master CHANNEL via

the Channel Module. The Maximum Flow Rate

and Minimum Flow Rate for the JOB determine

the scaling applied to this analog input. Analog

control is initiated when the input signal is greater

than 0.25 volts and the RIO Set Point is zero.

Note: When configured for current loop input,

the minimum 0.25 volts is achieved since 4 ma

produces 2.00 volts at the input due to the 500

ohm shunt resistor used in current loop mode.

Load Mode

LOAD MODE is similar to RUN MODE. However,

in LOAD MODE, up to 10 faults are permitted be-

fore the gun will leave LOAD MODE and enter the

FAULT MODE. All eleven (11) faults will appear

in the Error Log screen. The GUN will automati-

cally leave LOAD MODE and return to the READY

MODE after a volume greater than or equal to

the Mixed Volume has flowed since the last fault.

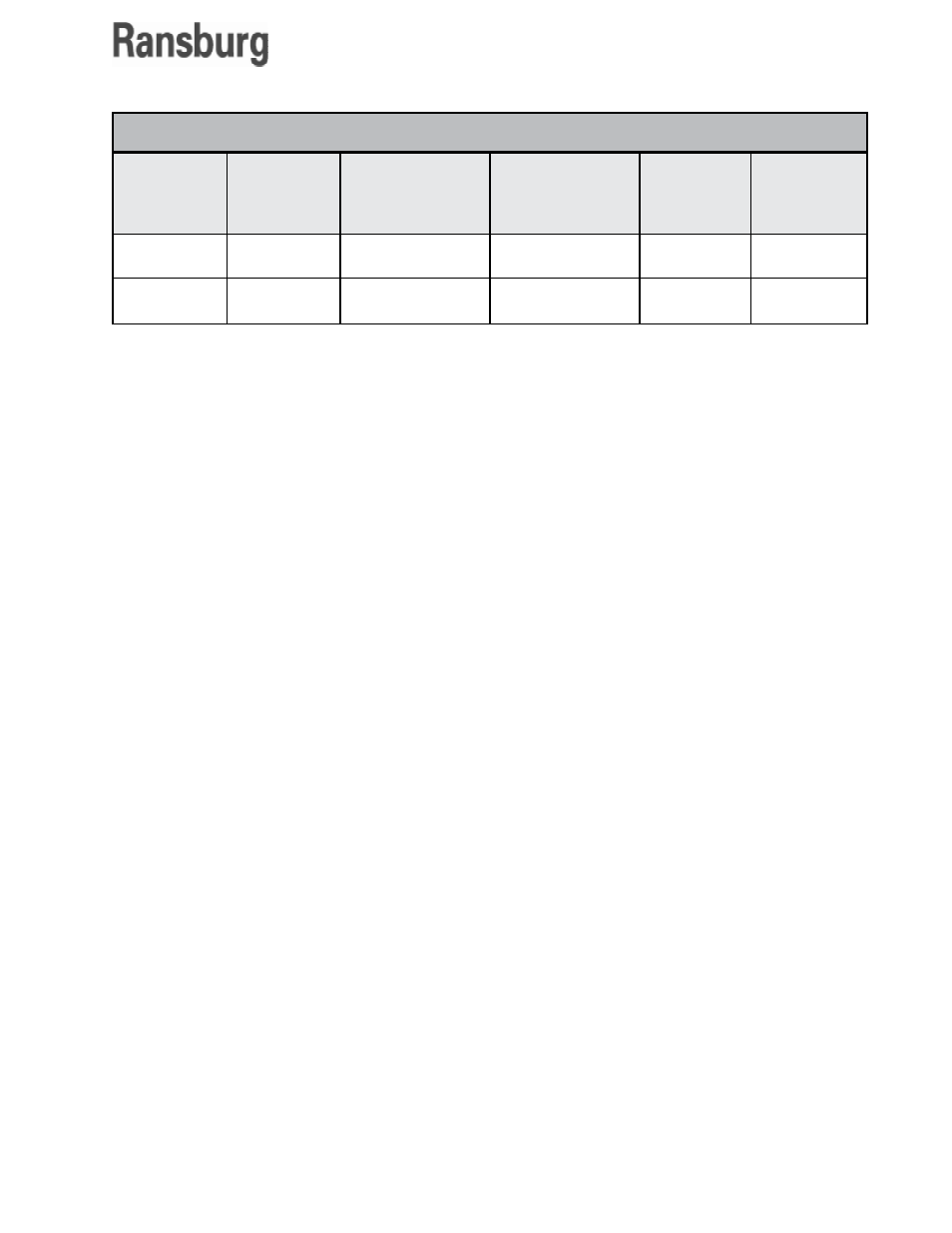

Minimum

Flow Rate

CC's/Min

Maximum

Flow Rate

CC's/Min

0

100

100

300

Minimum

Voltage or

Current

0 volts or 4 ma

0 volts or 4 ma

10 volts or 20 ma

10 volts or 20 ma

Maximum

Voltage or

Current

CC's/Volt

10.00

20.00

6.25

12.50

CC's/Ma

ANALOG CONTROL SETTINGS

To Place A GUN In LOAD MODE:

1. The external GUN enable input must be sup-

plied to the Master CHANNEL. No system or GUN

faults can be active and the GUN configuration

and JOB tables should be properly set.

2. A signal must be supplied to the Master CHAN-

NEL LOAD input or a LOAD command issued from

the Operator Interface Panel or the host controller.

3. Flow will begin when the Trigger signal is sup-

plied.

To Exit LOAD MODE:

1. Simply remove the LOAD input and apply the

HALT input or issue a command from the Opera-

tor Interface Panel.

MANUAL HAND GUN

APPLICATIONS

The DynaFlow controller can provide closed loop

regulation for manual hand GUN application of

two-component materials. When used with hand

spray GUNs, the painter regulates the total fluid

flow with the spray GUN or an inline fluid regulator.

Regulation of two-component materials is based

on pre-set ratios located in the JOB tables.

When the GUN is placed in RUN MODE, the

master channel (resin) goes full open, or to the

setting specified for that channel as MVR HIGH,

and stays at that value. The slave channel goes

to the pressure setting specified for that channel

by MVR LOW. The controller determines the flow

45

DynaFlow

TM

User Manual - Operation