Dynaflow, User manual - maintenance, Error codes (cont.) – Ransburg DynaFlow User Manual User Manual

Page 68

LN-9400-00.9

DynaFlow

TM

User Manual - Maintenance

64

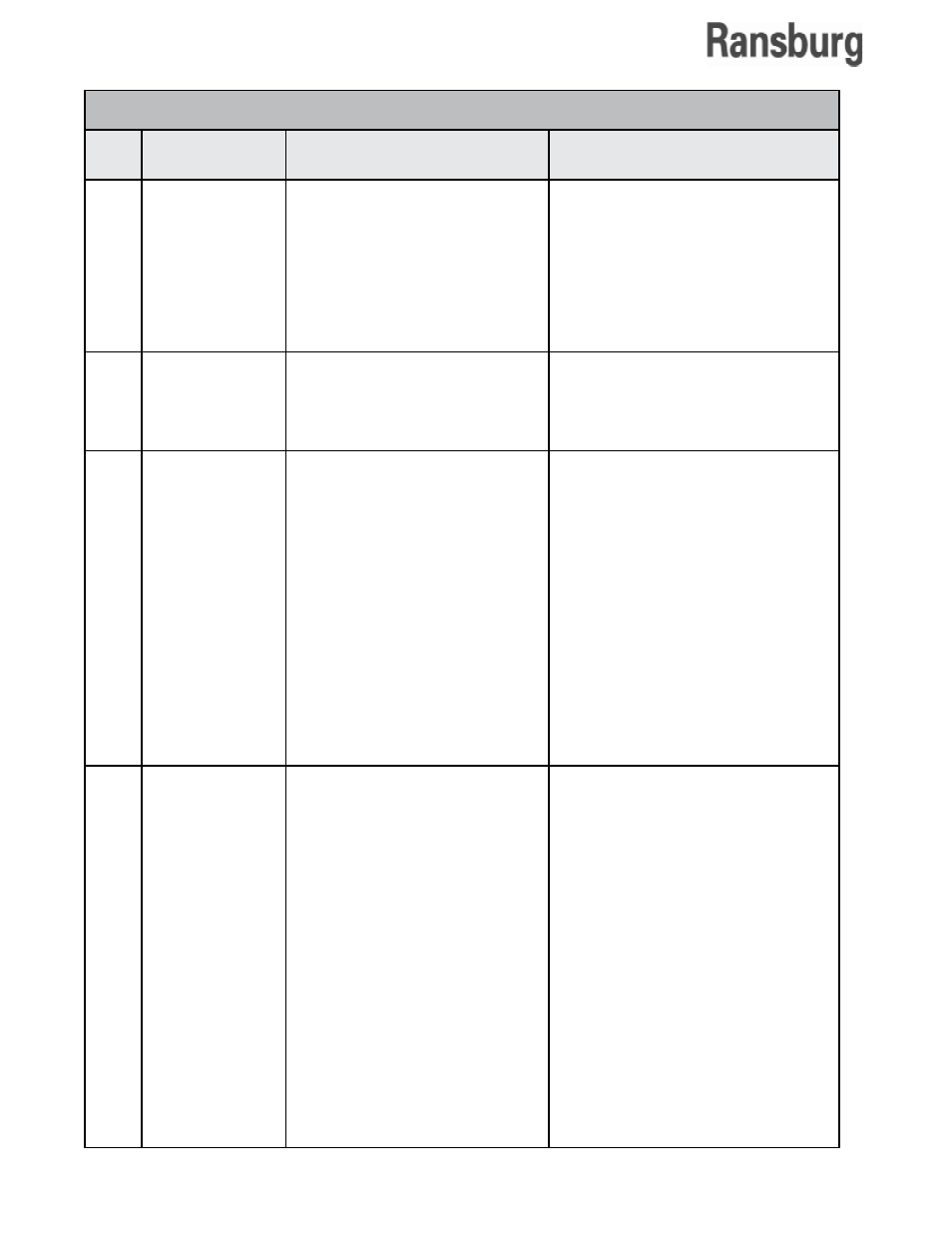

Displayed Text

Fault Cause

Corrective Action

External GUN EN-

ABLE Input Not

Detected

24 VDC must be supplied to the

external GUN ENABLE input before

the GUN can be placed in an active

state. This is typically used as an

interlock with other equipment or

hard-wired directly to 24 VDC.

Check for 24 VDC on the external

GUN ENABLE input.

Code

9081

9082

9083

9084

9085

9086

9087

9088

9091

9093

9095

9097

Channels Not

Present

Channel Module is not installed or

has failed.

1. Insert Channel Module or change

GUN configuration.

2. Reboot system and check again.

3. Replace Channel Module.

9111

9112

9113

9114

9115

9116

9117

9118

Out of Tolerance

-Catalyst Too High

CHANNEL #<>

The indicated slave (catalyst) CHAN-

NEL is above it's maximum toler-

ance limit as specified by the FLOW

TOLERANCE parameter.

Check the following:

1. Kp or Ki gains set too high.

2. Running the wrong JOB #, which may

include the wrong gain values.

3. Fluid pressures. Either reduce the

catalyst supply pressure or increase the

resin pressure. Try to maintain normal

operating pilot pressures to the fluid

regulators, between 30-60 psi.

4. The MVR LOW JOB parameter for

the catalyst is set too high (above the

regulator cracking pressure).

5. Air bubbles or cavitation.

Last digit indicates

CHANNEL #.

9211

9212

9213

9214

9215

9216

9217

9218

Out of Tolerance

-Catalyst Too Low

CHANNEL #<>

The indicated slave (catalyst) CHAN-

NEL is below it's minimum tolerance

limit as specified by the FLOW TOL-

ERANCE parameter.

Check the following:

1. Kp or Ki gains set too low.

2. Running the wrong JOB #, which

may include the wrong gain values.

3. Fluid pressures. Either increase the

catalyst supply pressure or decrease the

resin pressure. Try to maintain normal

operating pilot pressures to the fluid

regulators, between 30-60 psi.

4. Requested flow rate exceeds capa-

bility of the catalyst channel at the given

fluid supply pressure. Reduce total flow

rate or increase catalyst supply pres-

sure.

5. Air bubbles or cavitation.

Last digit indicates

CHANNEL #.

ERROR CODES (Cont.)