Dynaflow, User manual - maintenance, Error codes (cont.) – Ransburg DynaFlow User Manual User Manual

Page 69

LN-9400-00.9

DynaFlow

TM

User Manual - Maintenance

65

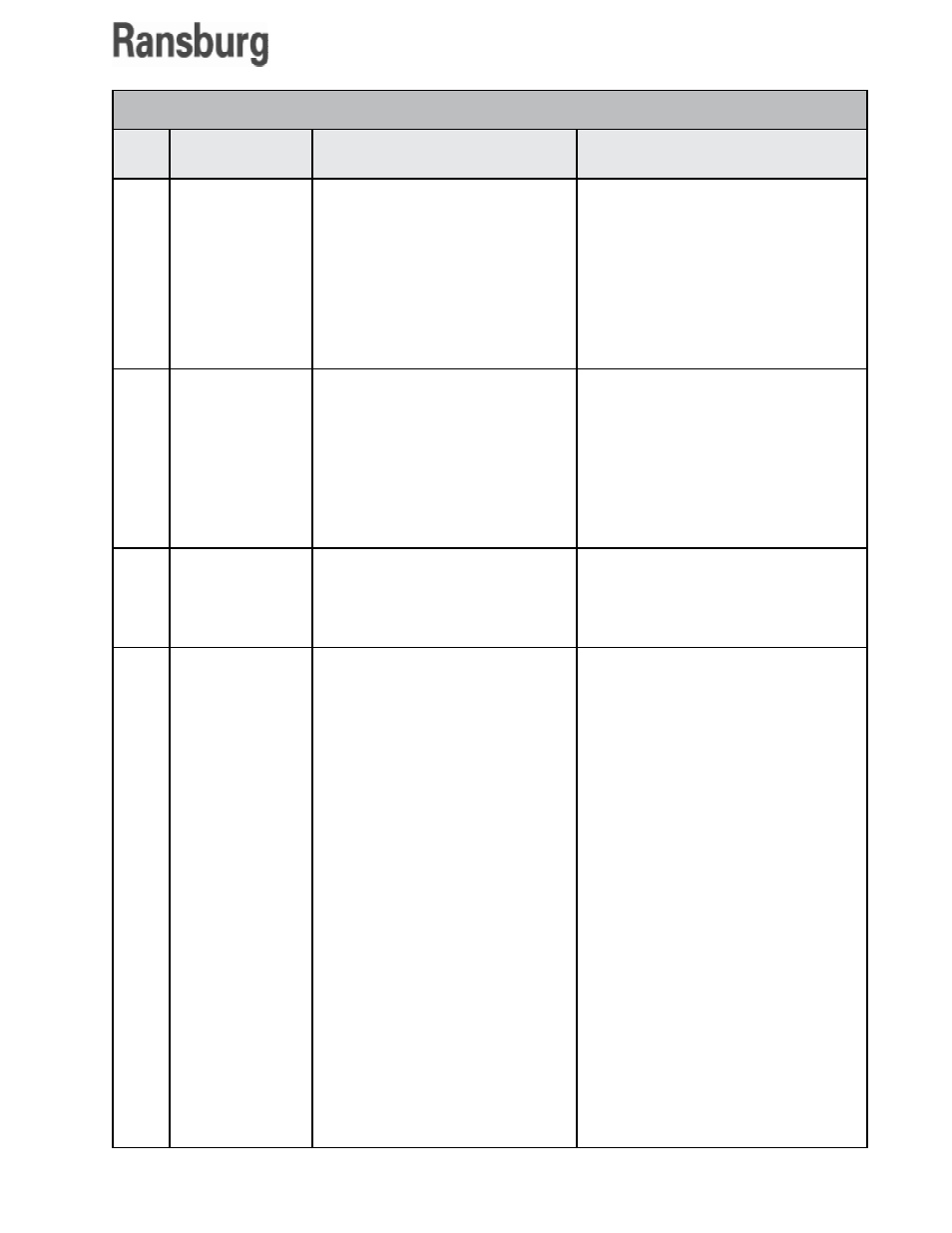

Displayed Text

Fault Cause

Corrective Action

Non-Existent

Program -

GUN #<>

JOB # number entered for the indi-

cated GUN does not exist. JOB #

number defaulted to 00.

Last digit indicates

CHANNEL #.

Verify the following:

1. The JOB # has been saved in memory

for the indicated GUN.

2. The correct JOB # is being re-quest-

ed.

3. For discrete hard-wired JOB # select,

PROGRAM TOGGLE and JOB # inputs

have been asserted correctly by the PLC

or host computer.

Code

A011

A012

A013

A014

A015

A016

A017

A018

A021

A022

A023

A024

A025

A026

A027

A028

B001

B010

GUN Flow Out of

Range

System Halted

RIO - Communi-

cations Error

The total flow rate for GUN # has

exceeded the MAXIMUM FLOW

RATE JOB parameter or fallen below

the MINIMUM FLOW RATE JOB

parameter. For Manual GUNs only.

System Ready/Halt input is

inactive.

PLC and DynaFlow are not set to

the same:

- baud rate

- rack address

- rack size

- rack starting quarter

RIO cable is not connected to the

proper terminals at either end.

See "Flow Too Low" and "Flow Too

High" faults.

This input is typically used as an interlock

to other control equipment or it is simply

hard-wired to 24 VDC. Supply 24 VDC

to the System Ready/Halt input.

Check with the PLC programmer to de-

termine the correct values for baud rate,

rack address, rack size, and rack start-

ing quarter and then set the DynaFlow

Interface Module DIP SW1 and SW2 to

the appropriate settings per "Interface

Module DIP SW2 Settings" and "Mother

Board Signal ID (J3, J4, J5, J6 Channel

Cards" respect-ively in this section.

Check cable connections per Figure 25

ERROR CODES (Cont.)