D-25 – Rockwell Automation 1785-Lxxx Enhanced and Ethernet PLC-5 Programmable Controllers User Manual

Page 325

Publication 1785-UM012D-EN-P - July 2005

Instruction Set Quick Reference D-25

Process Control, Message Instructions

Block Transfer Instructions

Word 0

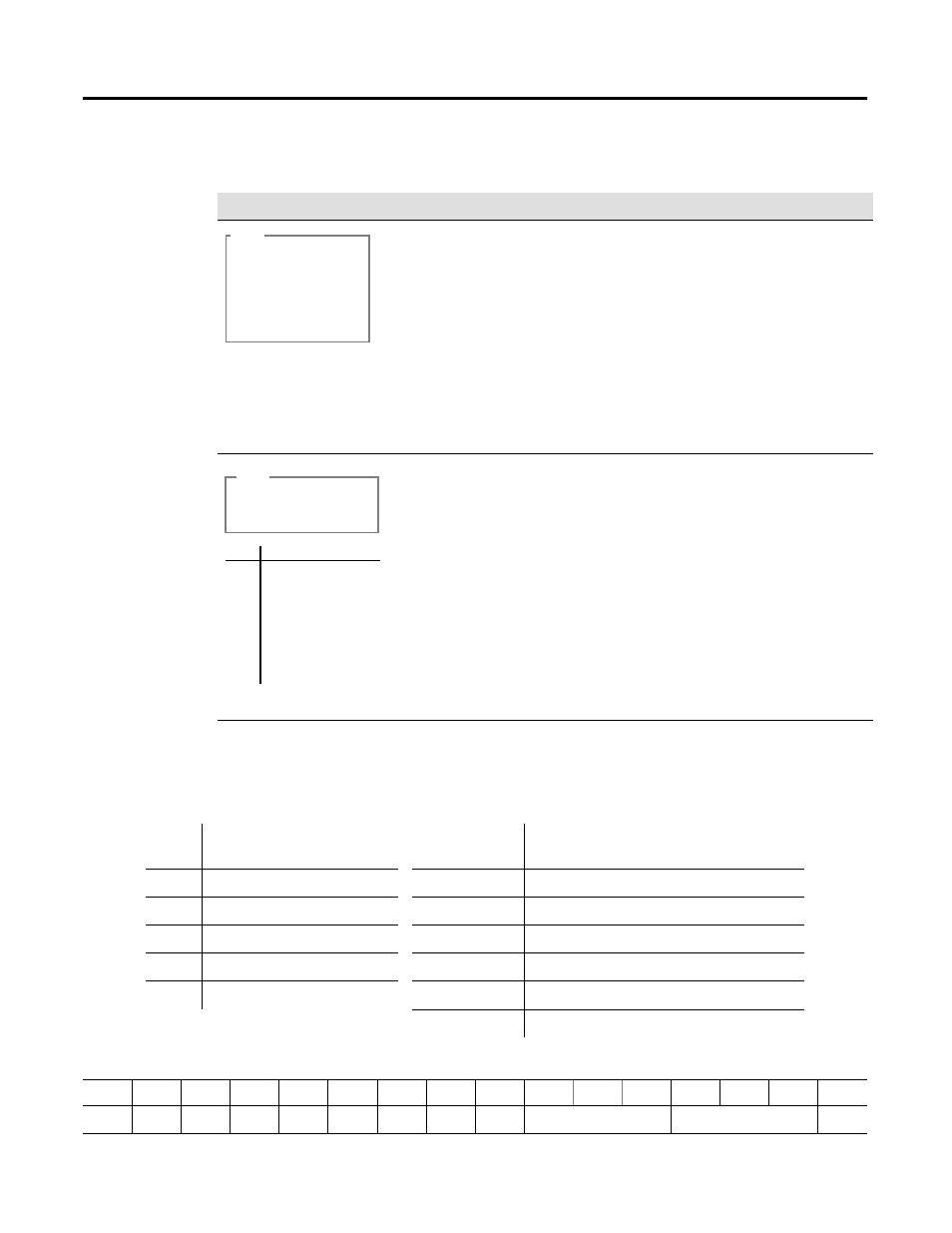

Instruction

Description

Proportional, Integral,

and Derivative

PID

Status Bits:

EN - Enable

DN - Done Bit

(for N

control blocks only)

The control block (PD10:0) contains the instruction information

for the PID. The PID gets the process variable from N15:13 and

sends the PID output to N20:21. The tieback stored in N15:14

handles the manual control station.

If you use an N control block, the rung must transition from

false to true for execution.

If you use PD control block, then there is no done bit. Also, the

rung input conditions need to be true.

See page F-8 for a description of prescan operation for

this instruction.

If the input conditions go from false to true, the data is

transferred according to the instruction parameters you set

when you entered the message instruction. The Control Block

(MG7:10) contains status and instruction parameters.

You can also use N control blocks.

For continuous MSGs, condition the rung to be true for only one

scan.

See page F-8 for a description of prescan operation for

this instruction.

PID

PID

PD10:0

Control Block

Proc Variable

Control Output

Tieback

N15:13

N20:21

N15:14

MSG

SEND/RECEIVE MESSAGE

Control Block

MG7:10

Bit #Status Bits

15EN - Enable

14ST - Start Bit

13DN - Done Bit

12ER - Error Bit

11CO - Continuous

10EW - Enabled-Waiting

9NR - No Response

Integer (N) control block

Block Transfer (BT) control block

Word

Offset

Description

Word

Mnemonic

Description

0

status bits (see below)

.EN through .RW

status bits

1

requested word count

.RLEN

requested length

2

transmitted word count

.DLEN

transmitted word length/error code

3

file number

.FILE

file number

4

element number

.ELEM

element number

.RGS

rack/group/slot

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

EN

ST

DN

ER

CO

EW

NR

TO

RW

** rack ** **

group** slot