Calculating worst-case remote i/o scan time, Optimizing remote i/o scan time – Rockwell Automation 1785-Lxxx Enhanced and Ethernet PLC-5 Programmable Controllers User Manual

Page 295

Publication 1785-UM012D-EN-P - July 2005

Maximizing System Performance C-9

Calculating Worst-Case Remote I/O Scan Time

Since it is impossible to predict within which remote I/O scan a block-transfer

will occur, you only can calculate the worst-case remote I/O scan time. To

calculate the worst case time:

1. Determine the normal I/O time (without block-transfers)

2. Add the time of the longest block-transfer to each entry in the scan list.

(The controller can only perform one block-transfer per entry in the

scan list per I/O scan.)

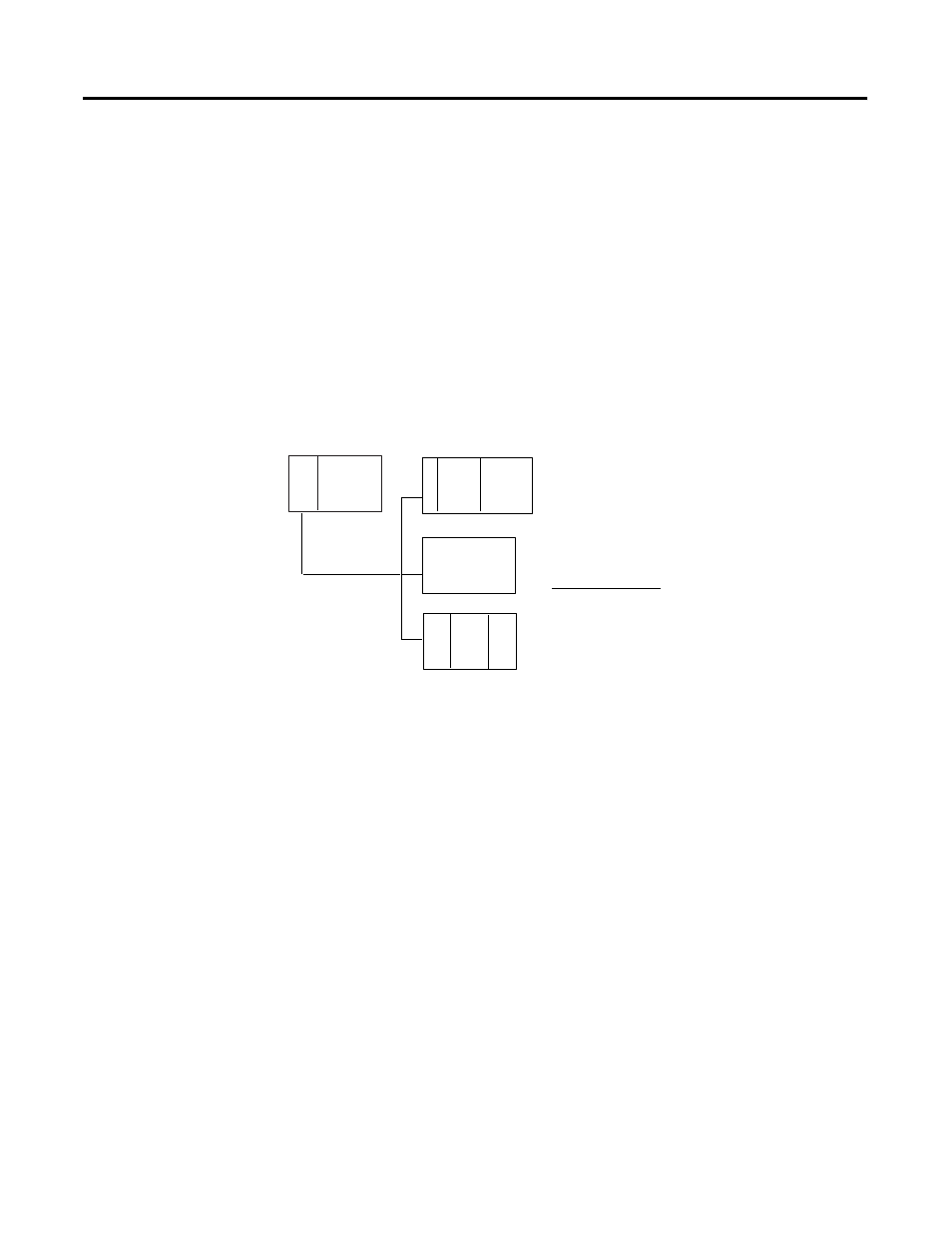

For example, if your system is:

Optimizing Remote I/O Scan Time

The best way to optimize your scan time is to place your most time-critical

I/O on a separate channel from non-critical I/O. If you have only one

channel available for I/O, however, you can still optimize the scanning by

using the controller’s configurable scan list.

In a normal 4-rack system, the scan list would be:

rack 1

rack 2

rack 3

rack 4

If you are using 57.6 kbps, the normal I/O scan is 4 racks x 10 ms = 40 ms.

Each entry is of equal priority, so each rack is scanned every 40 ms.

PLC

115.2 kbps

Rack 1

Rack 2

Rack 3

No BTs

BT

30

words

BT

10

words

BT

20

words

Worst-case I/O scan:

(3 x 6)

+ (20 x .14) + 2.5

+ 0

+ (30 x .14) + 2.5

3 racks at 115.2 kbps*normal I/O scan

longest BT in rack 1

no BTs in rack 2

longest BT in rack 3

18 + 5.3 + 0 + 6.7 = 30 ms