5 description of functions.pdf – KROHNE OPTIMASS with MFC 05x EN User Manual

Page 69

Installation and Operating Instructions OPTIMASS

68

5 Description

of

Functions

In all the following examples, a short notation is used for the setting of the signal converter. Pushing a

key several times is indicated by the number of times without the intermediate display messages. Only

the final display output is listed.

5.1 Menu 1 - Initial Start up

Zero Point Adjustment Fct. 1.1

When operating the system for the first time, it is necessary to set the zero point of the instrument.

Once the zero point has been adjusted, the installation should not undergo any further modifications in

order to maintain the quality of the measurement. This means that after system changes (such as the

piping or changing the calibration factor), it is advisable to re-adjust the zero-point.

To achieve a successful zero calibration the primary head should be completely full of process fluid at

normal operating pressures and temperatures. Ideally there should be no air inclusions in the fluid,

particularly for horizontal installations, so it is recommended that the primary head be flushed with the

process fluid at a high flow rate (>50%), for 2 minutes, prior to starting the adjustment. After flushing,

flow in the primary head must be brought back to zero by tightly closing appropriate valves.

The zero off-set can either be measured automatically or entered manually using the display keys. If an

automatic adjustment is to be made then the operator should trigger this, with the front cover still in

place, using the bar magnet provided to operate the magnetic sensors on the display. This is to ensure

that the zero adjustment is carried out with the mechanical installation exactly the same as for normal

operation.

Begin from the measuring mode.

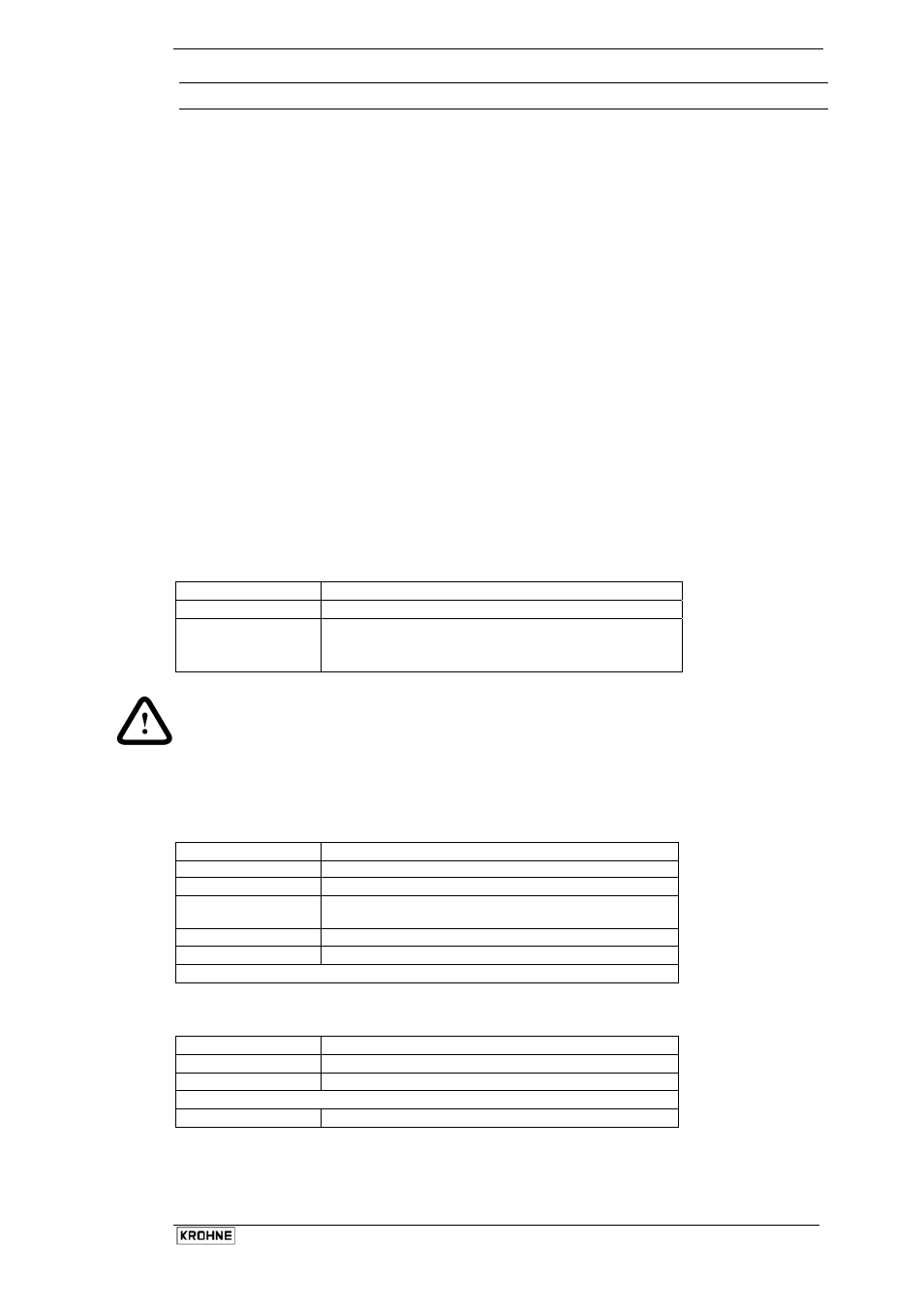

Key Display

→

x 2

Fct. 1.(1) ZERO CALIB.

→

Fct. 1.1.(1) AUTO CALIB.

or

↑

Fct. 1.1.(2) MAN CALIB.

Note :

The brackets around parts of the above text indicates the cursor position, these characters will be

flashing on the display. Flashing values can now be changed with the ↑ key. Pressing the → key moves

the cursor to the next ”field” which then starts to flash.

The operator can now choose either A) Automatic (recommended) or B) manual adjustment.

A) Automatic adjustment::

Key Display

Fct 1.1.(1) AUTO CALIB

→

SURE (YES)

↵

X.XXX

PERCENT*

↵

ACCEPT (YES)

4x↵

Return to measuring mode.

* Display of actual flow rate % of maximum value, for a period of 30 seconds.

B) Manual adjustment:

Key Display

Fct. 1.1.(2) MANUAL CALIB.

→

(+)0.0000000 g/sec

Input value using ↑ to change sign and digit and → to move cursor.

5x↵

Return to measuring mode.