4 mechanical installation 8000-9000.pdf – KROHNE OPTIMASS with MFC 05x EN User Manual

Page 31

Installation and Operating Instructions OPTIMASS

30

1.4 OPTIMASS 8000 / 9000 Meter with Twin U Measuring Tubes

1.4.1 Specific Installation Guidelines

•

Tighten flange bolts evenly.

•

Do not stress the sensor mechanically. Clamp and support the connecting pipework accordingly.

•

It is permissible to support the weight of the meter on the square body.

•

Cavitation and Mechanical vibration should be avoided.

•

Use of standard pipework reducers at the flange is allowed. Avoid extreme changes in pipe size

(step changes).

•

The use of flexible hoses directly at the meter is not permitted.

•

Installation below 0°C - mount vertically, or horizontally with converter up to prevent freezing or

condensation in housing.

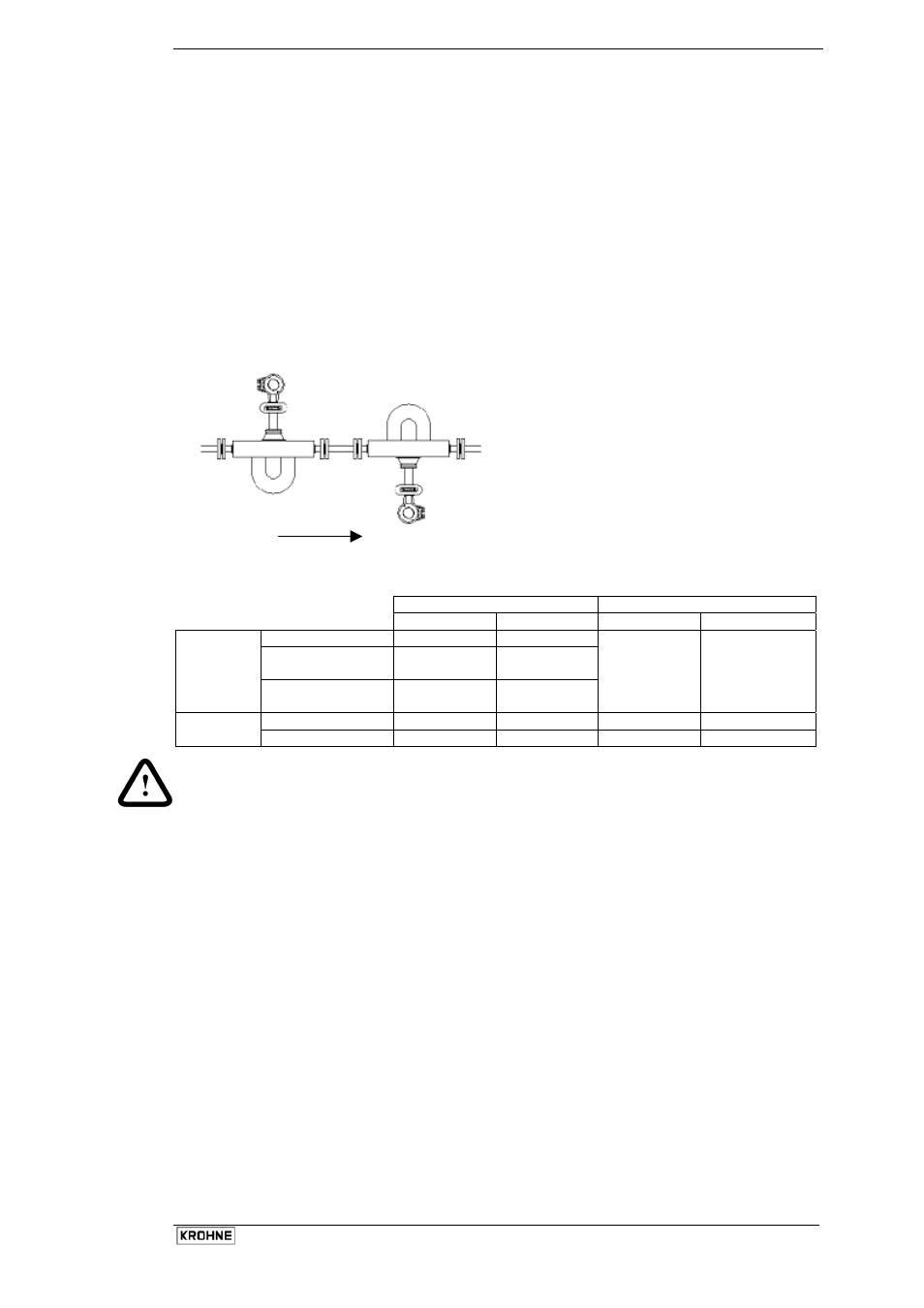

Horizontal Mounting:

For liquids, measuring tube downwards so that

no gas collects in tube if no-flow.

For gasses, measuring tube upwards, so no

liquids can collect if no-flow.

1.4.2 Ambient / Process temperatures

The specified and approved ambient and process temperatures must be observed.

8000

9000

°C °F °C °F

Safe Area

-180 .. +230

-292 .. +446

ATEX/FM/CSA -

Compact

-40 .. +190

-40 .. +374

Process

ATEX/FM/CSA -

Remote

-40 .. +230

-40 .. +446

0 .. +350

0 .. 662

Compact

-40 .. +55

-40 .. +130

-

-

Ambient

Remote

-40 .. +60

-40 .. +140

-40 .. +60

-40 .. +140

Note:

Where meters are mounted in direct sunlight, it is recommended to install a sunshade. This is

particularly important in countries with high ambient temperatures.

The maximum differential temperature between the process and ambient temperature without insulation

is 80°C or 176°F.

1.4.3 Pressure Equipment Directive (PED) requirements.

To comply with the requirements of the PED in Europe, the following information is provided to assist the

plant engineer in installing the meter.

Measuring tube: Stainless SS 316L

Sealing Faces:

Stainless SS 316L

Hastelloy

C22

Hastelloy

C22

Flanges: SS316L

Casing:

Stainless Steel 316

Typical burst pressure of case is in excess of 50 bar @ 20°C

Not PED approved

Insulation is strongly recommended above 100°C

For insulated meters without heating jackets, repeated heating or cooling at rates > 30°C per hour

should be avoided to increase operational lifespan of meter.

Liquids

Gasses