KROHNE OPTIMASS with MFC 05x EN User Manual

Page 13

Installation and Operating Instructions OPTIMASS

12

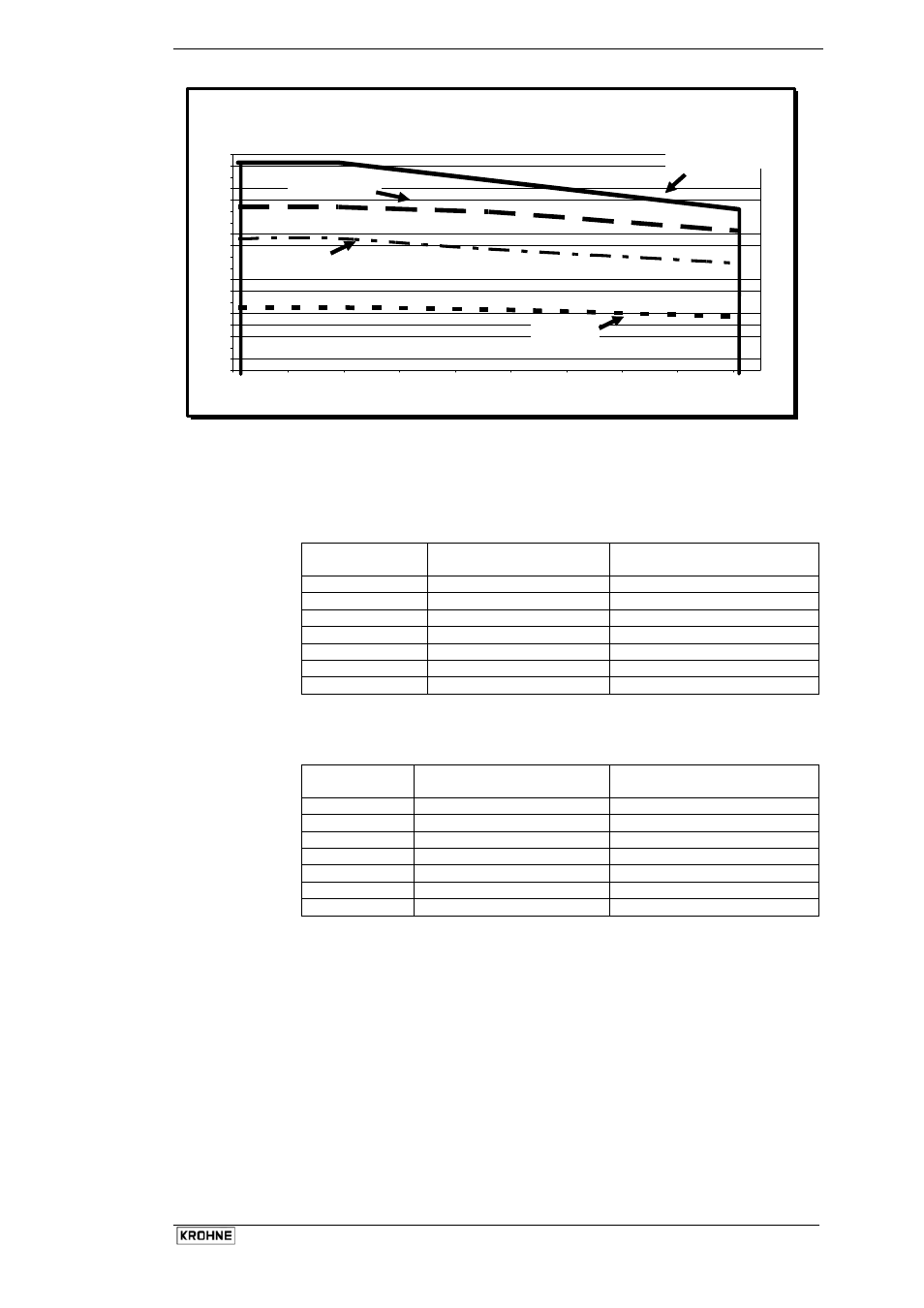

Pressure/Temperature de-rating for SS and Hast. C22

ANSI 150 and 300 lbs

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

30

50

70

90

110

130

150

170

190

210

Temperature in Deg. F

P

ressu

re i

n

p

si

Secondary Pressure

Containment 316 L

ANSI 300 lbs

ANSI 150 lbs

Secondary Pressure

Containment 304 L

Maximum pipe work forces

The maximum forces exerted on the meter from the pipe work, compressive or tensile has been

calculated for the 7000 Series (Straight tube meter) with Titanium, Hastelloy and SS measuring tubes

as follows:

Titanium

Size

Max

Force:

Flanges

Max Force:

Hygienic Connectors

06 T

19 KN

1.5 KN

10 T

25 KN

2 KN

15 T*

38 KN

5 KN

25 T

60 KN

9 KN

40 T

80 KN

12 KN

50 T

170 KN

12 KN

80 T

230 KN

30 KN

*On OPTIMASS 15 T with ½” ANSI flanges only – maximum end load is 19 KN.

Hastelloy and SS

Size

Max

Force:

Flanges

Max Force:

Hygienic Connectors

06 S

19 KN

1.5 KN

10 H/S

25 KN

2 KN

15 H/S*

38 KN

5 KN

25 H/S

60 KN

9 KN

40 H/S

80 KN

12 KN

50 H/S

80 KN

12 KN

80 H/S

170 KN

18 KN

*On Optimass 15 H or S with ½” ANSI flanges only – maximum end load is 19 KN

Loads given in both tables are maximum static loads. If loads are cycling, particularly between tension

and compression then these loads should be reduced.

Please consult KROHNE for more information.