KROHNE OPTIMASS with MFC 05x EN User Manual

Page 52

Installation and Operating Instructions OPTIMASS

51

3.3 Zero point adjustment

After installation adjust the zero point. To do this, the primary head must be completely filled with the liquid

product without gas or air inclusions. This is best obtained by allowing the liquid product to flow through

the primary head for approx. 2 minutes at a throughput rate of greater than 50% of rated flow.

Subsequently ensure that flow comes to a complete stop in the primary head (see Section 1.1) for setting

the zero without interruption to product flow, use a bypass set-up as shown in Section 1.1.

Now initiate zero adjustment by way of the following keystroke combination:

Start from measuring mode

Key Display

Line 1

Line 2

→

Fct. (1)

OPERATION

2x→

Fct. 1.1.(1)

AUTO. CALIB.

↑

CALIB.

(YES)

↵

X.X PERCENT

ACCEPT.

(YES)

↵

Fct. 1.1.(1)

AUTO. CALIB.

3x↵

ACCEPT.

(YES)

↵

Display

Under certain conditions, it may not be possible to adjust the zero point:

•

If the medium is in motion. Shut-off valves not tightly closed.

•

If there are gaseous inclusions in the primary head. Flush the primary head and repeat the calibration.

•

If resonant oscillations of the piping are interfering with the primary head. If there are active warning(s)

in the status message list. (See section 6)

In such cases, the zero point adjustment procedure is automatically aborted and the following message is

displayed:

ZERO.ERROR

Press

↵

and then the converter returns to the start of the function 1.1.1:

Fct. 1.1.1 AUTO. CALIB

Further information on zero point adjustment is given in Section 4.

The OPTIMASS is ready to operate after zero has been adjusted.

All parameters have been factory-set in keeping with the data specified in your order.

Detailed information for further setting of the signal converter will be found in section 4 and 5 of the

operating instructions.

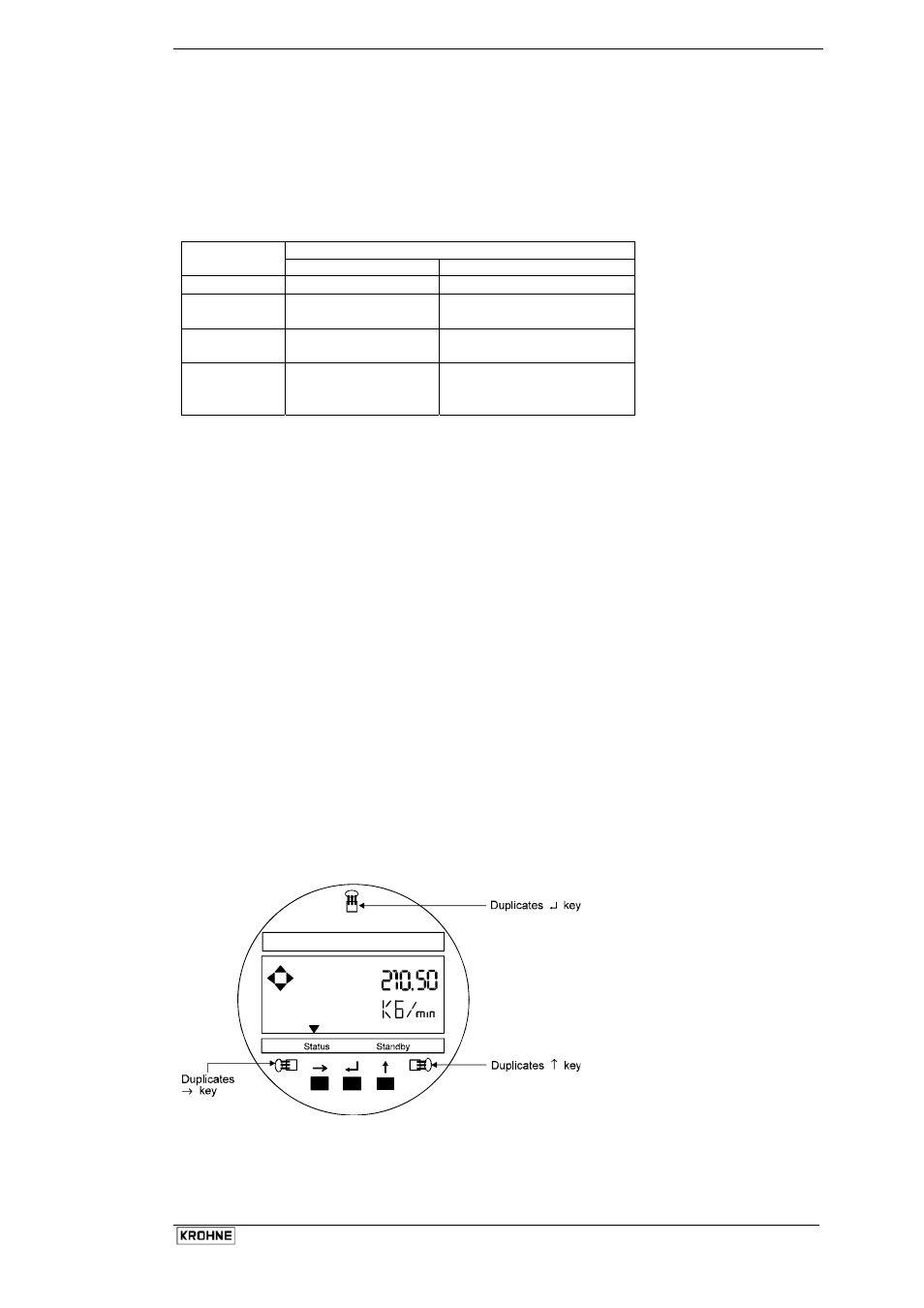

3.4 Programming the converter with a bar magnet

•

The converter can be programmed by means of the magnetic sensors mounted on the faceplate

without removing the front lid.

•

To do this, a bar magnet (standard supply) is used to activate the sensors by holding the magnet close

to the glass window of the housing lid.

•

These sensors then duplicate the functions of the push buttons.

KROHNE MFC 50

•

This is mandatory in Ex

environments

•

Also recommended in

humid environments