KROHNE OPTIMASS with MFC 05x EN User Manual

Page 36

Installation and Operating Instructions OPTIMASS

35

1.4.8 Purge Port Meters and Burst Disk Meters

Purge Port Options

If the purge port option was selected at time of order, then your meter will be fitted with 1/4" NPT female

connections – these will be clearly identified. These connections are sealed with NPT plugs and PTFE tape.

Important:

Do not remove these plugs.

The meter is factory sealed with a dry nitrogen gas fill and any ingress of moisture will damage the meter.

The plugs should only be removed to purge the inside of the meter case of any product if it is suspected that

the primary measuring tube has failed. This must only be done after the meter has been depressurised and

removed from service. This should be done as soon as possible after failure is suspected (less than 3 days)

Burst Disk meters

OPTIMASS 8000/9000 meters that have been ordered with a bursting (rupture) disk will be so fitted. This is

fitted when the operating pressure of the measuring tube exceeds the design pressure of the secondary

containment. The disk failure pressure is 20bar @ 20°C.

Important:

The burst disk is suitable for the designed application according to the process conditions and flow rates as

per original order. If conditions alter, consult KROHNE for further advice regarding suitability of disk fitted.

If the product is in any way hazardous, it is strongly recommended that an exhaust tube is connected to the

3/4" NPT male thread of the burst disk so that the discharge can be piped to a safe area. This tube should

be large enough that pressure cannot build up in the meter case.

Ensure arrow on burst disk is pointing away from meter.

1.4.9 Technical Data

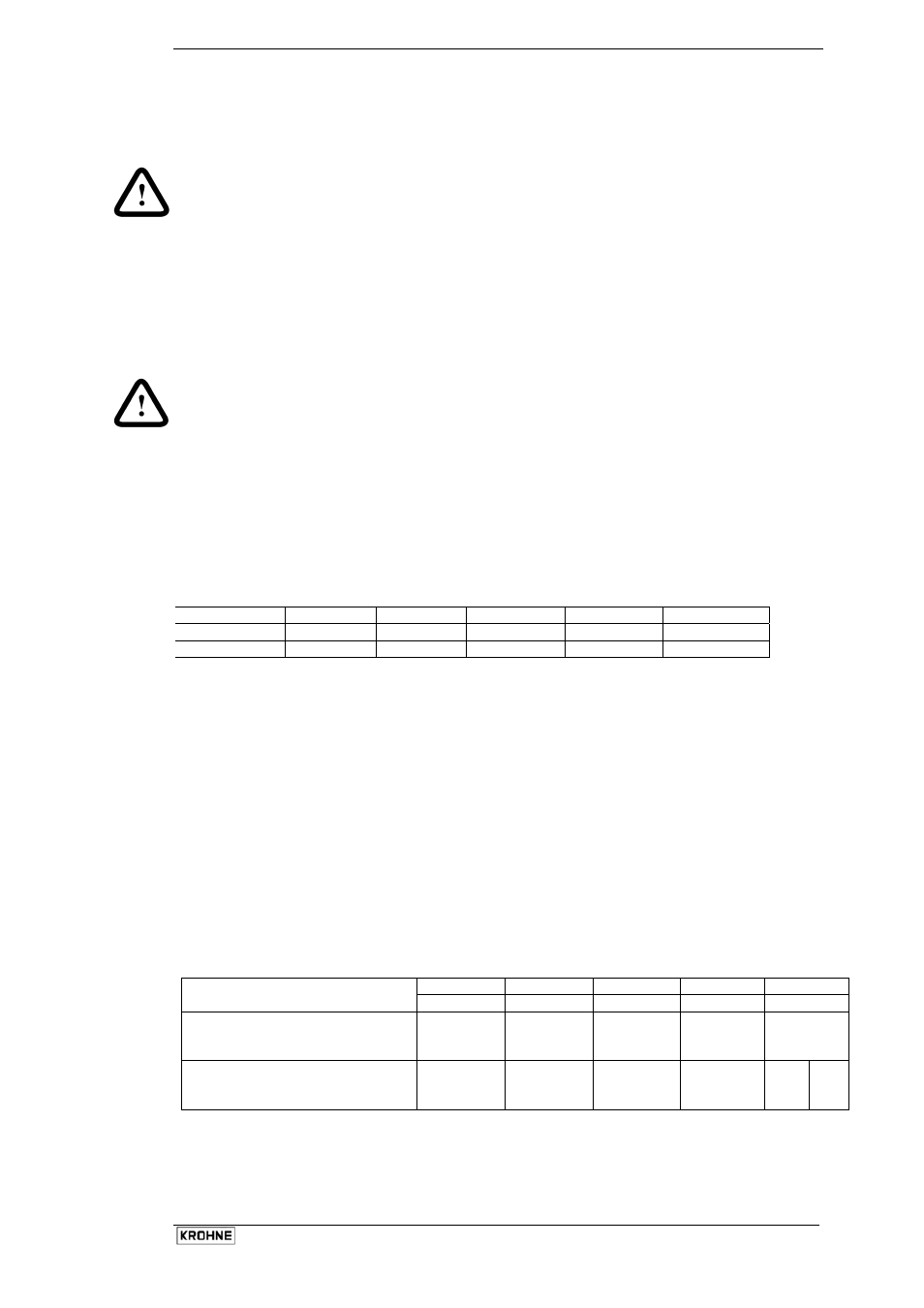

Nominal Flow Rates

15

25

40 80 100

Kg/h

2,700 9,000 32,000 85,000 250,000

Lbs/min

100 300 1,200 3,000 9,300

Maximum flow rate

Typically 130 % of the nominal flow rate for the sensor size depending on application.

Minimum flow rate

Depending on measuring error required.

Materials of construction

Measuring Tubes

SS 316L or HC-22

Flanges

SS 316L or

SS316L backing with HC-22 raised face

Outer Casing

SS 304

Converter Mount & Front End electronics

SS 316L

1.4.10 Weights & Dimensions

Weights

Weight of OPTIMASS 8000/9000 sensor fitted with a typical standard flange in kg (lbs)

15 25 40 80 100

Model / Size

kg lbs kg lbs kg lbs kg lbs kg lbs

8000

Sensor

10.9 24 14.4 32 23.4 51.5 61.4 135 89.4 197

9000 Sensor with insulation

housing

14.9 32.8 20.4 44.8 30.9 68 79 174 125 275