Tubular (somfy) motor, Drive pipe assembly – Hired-Hand Unitized Mega Cool: Square Bottom User Manual

Page 28

Part No. 4801-5396 Rev 5-08

Unitized System – Square Reservoir

Page 28 of 63

Tubular (Somfy) Motor

Drive Pipe Assembly

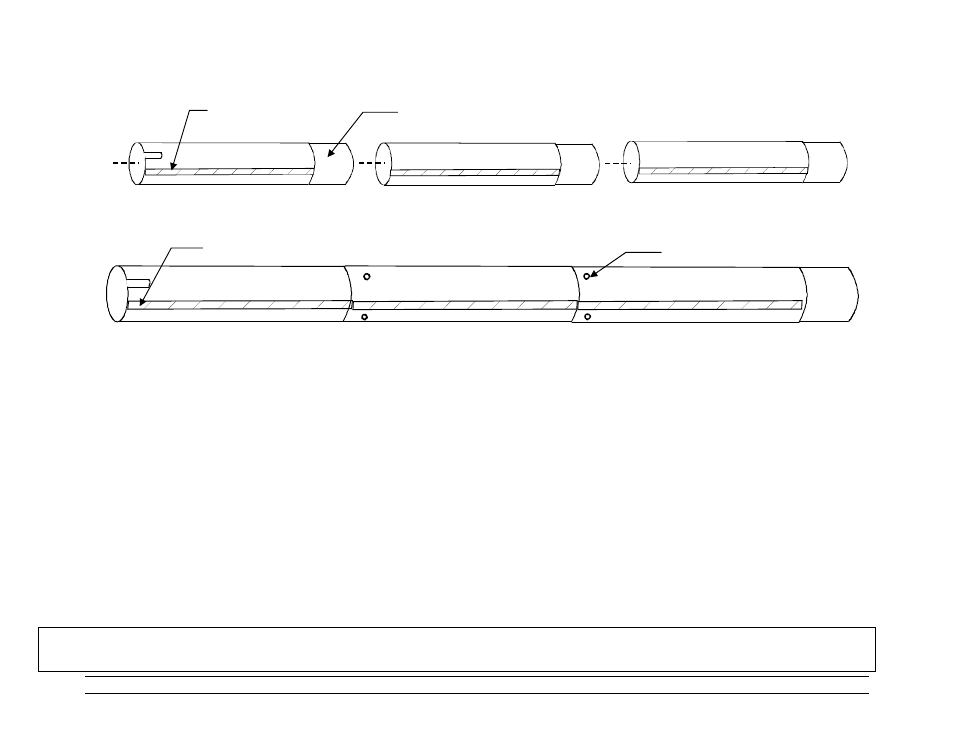

1. Starting at one end of the system, arrange the drive pipe

sections on the track end-to-end with the swedge ends

nonadjacent. (To assembly drive pipe on the ground, see

page 46.) For tubular motor: Place the slotted section of

pipe at the end of the assembly where the motor will be

installed. Lock motor: Place Lock motor drive end on end

where motor will be installed.

2. IMPORTANT! There is a hook and loop strip laminated to

each pipe section. Keep the hook and loop strips lined up

when connecting the pipe sections in order to form a

continuous hook and loop strip running the entire length of

the drive pipe.

3.

Couple pipe sections together by sliding the swedged end

of one section into the adjacent pipe. (NOTE: It might be

necessary to take a hammer and straighten out the dimples

in the ends of the pipes which were created when the pipe

sections were cut). Attach the sections together by

installing stainless steel pop rivets.

4. Before assembling the last drive pipe opposite the motor

end, check fit. If necessary, cut drive pipe to fit.

Allow .250 minimum, .375 maximum from inside wall of

bearing mount attachment.

NOTE: Pop rivet installation: Drill 3/16” (4.8 mm) dia. holes

through the pipe and swedged end which form a junction of

two pipe sections. At each junction, drill two holes about 2“

(5.08 cm) apart on each side of the pipe as shown in the

diagram above. Insert rivets through these holes to fasten the

pipe sections together.

Install stainless steel pop rivets.

Keep hook and loop strips aligned when assembling drive pipe.

7.5 mm (0.295”) x 35 mm (1.38”) Tubular motor only!

Swedged End

Hook and Loop

Strip

NOTE: If installing tubular motor, proceed to next section - 'Tubular Motor'. If installing Lock motor, go to Section

entitled ‘Lock Motor Installation’.