Hired-Hand Sens-O-Matic (Feed Hopper Switch) User Manual

Sens-o-matic ii, Description, Sens-o-matic ii™ assembly & installation

SENS-O-MATIC II™

Hopper Switch

HIRED-HAND, INC.

• 1733 County Road 68 • Bremen, AL 35033 USA • Phone 256-287-1000 • Fax 256-287-2000

Manual Part No. 4802-0134 rev 5-07 Page

1 of 2

WARNING!

Only qualified electrician personnel familiar with the

construction and operation of this equipment and the

hazards involved should install and/or service this

equipment. It is important that all standard electrical

codes be observed when wiring the Sens-O-Matic™.

Read and understand all instructions and diagrams

before proceeding. Failure to observe this precaution

could result in equipment damage, severe bodily

injury, or loss of life.

DESCRIPTION

The Hired Hand Sens-O-Matic II™ is an electronic

feed hopper switch which turns the feed auger On or

OFF depending on the hopper feed level. A NEW

FEATURE recently added is the Push-to-Reset

Circuit Breaker. The circuit breaker is externally

accessible and has replaced the internal glass tube

fuse which required opening the enclosure. The Sens-

O-Matic™ is a direct retrofit for the standard Paddle

Switch currently used in the poultry industry. If the

feed fill system and paddle-type Hopper Switch is

controlled by 240vac, a 240vac Sens-O-Matic™ is

required. If the feed fill system and paddle-type

Hopper Switch is controlled by 120vac, a 120vac

Sens-O-Matic™ is required. Installation of the Sens-

O-Matic™ is quick and simple with only three wire

connections as shown in the wiring diagram provided

on Page 2. Approximately 3 feet of electrical cord and

a slide-in mounting tab bracket are supplied

preattached to the Sens-O-Matic™. No assembly is

required. The Sens-O-Matic™ is preset for an

approximate 30 second time-delay from an Off state to

an activated On state when nothing is sensed near the

sensing area.

When the kit is received, check for shipping damage.

Contact Hired-Hand Customer Support for information

regarding the universal mounting bracket and external

power supply options if these options are required.

Part #

Description

6606-0110

SM-2-I-126S Sens-O-Matic™ 120v 60hz

6606-0114

SM-2-I-246S Sens-O-Matic™ 240v 60hz

6406-1126

/Universal Mount Bracket Assembly

6606-0112

SM-2-E-246S Sens-O-Matic™ 240v 60hz Ext Pwr Supply

6607-1598

PS-24VAC-250VA-120/240VAC Power Supply

Wire Stripper

Wire Connectors

Sens-O-Matic II™

Assembly & Installation

A. Disconnect AC electrical power from all equipment.

B. Place the Sens-O-Matic™ inside the feed hopper

and slide the mounting tab into the hopper retaining

slot.

NOTE: The feed tube should not be placed to allow the

feed to dump directly onto the Sens-O-Matic™.

C. Route and secure the Sens-O-Matic™ power cord in

a safe and secure location.

D. Connect the black, white, and green wires as shown

in the wiring diagram on Page 2.

E. Ensure that all wires are secure and safely clear

from moving/turning auger components.

F. Apply power and test the Sens-O-Matic™ with feed

to ensure proper operation.

WARNING!

• Remove ALL Electrical Power from the feed fill

system before installation / wiring.

• Never plug the Sens-O-Matic™ into a standard 120

or 240 VAC receptacle as serious injury may result.

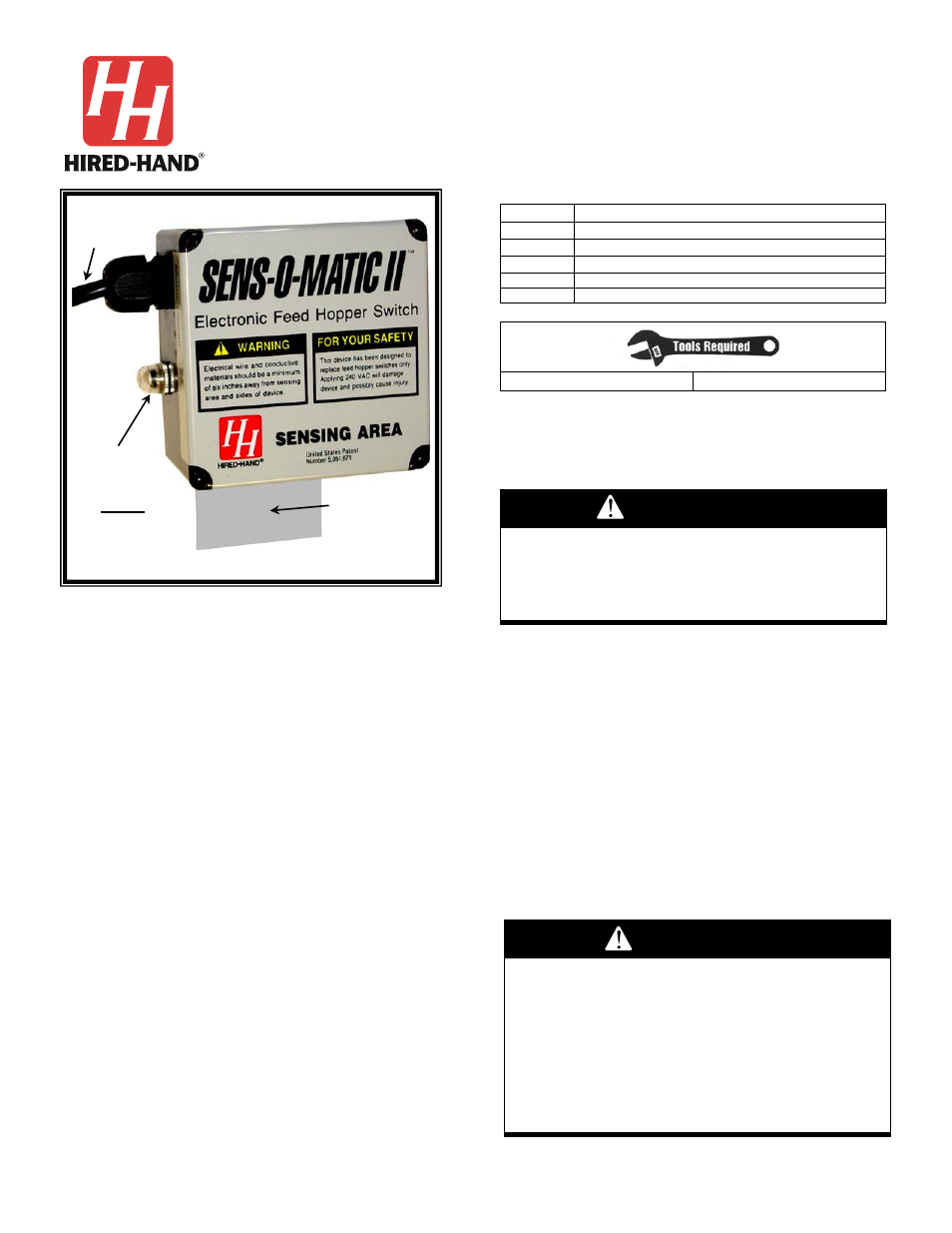

Figure 1: Sens-O-Matic II™ Control

Mounting Tab

PCB168

15 Amp

Push-to-Reset

Circuit Breaker

NEW

Power

Connection

* Patent Number: 5,051,671