Exhaust flow rates (min. recommended), Hood ventilation requirements – XLT XD-9010B User Manual

Page 64

64

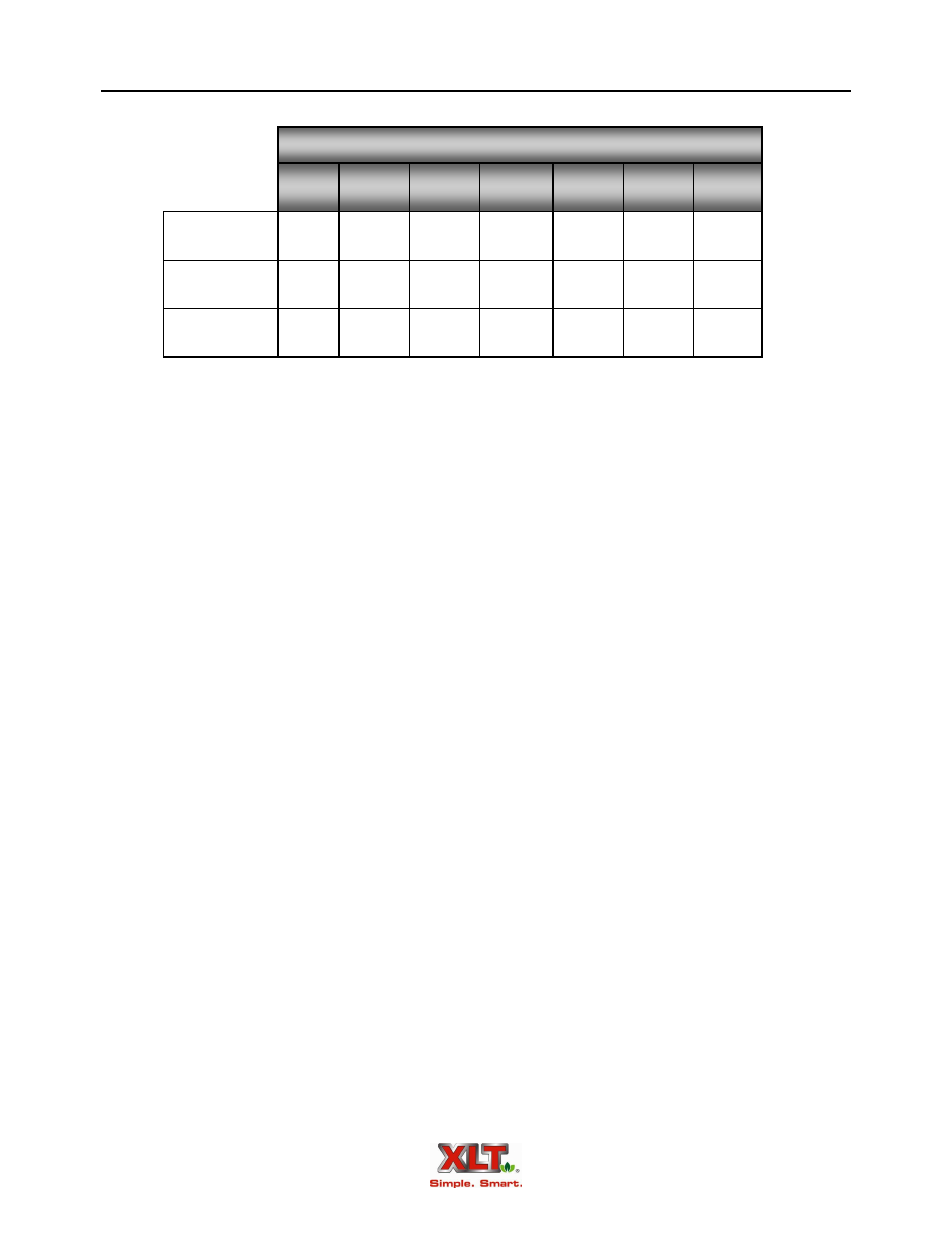

Exhaust Flow Rates (min. recommended)

AVI

1832

AVI

2440

AVI

3240

AVI

3255

AVI

3270

AVI

3855

AVI

3870

Single

246

[6.97]

313

[8.86]

402

[11.38]

402

[11.38]

469

[13.28]

402

[11.38]

469

[13.28]

Double Stack

506

[14.33]

644

[18.24]

828

[23.45]

828

[23.45]

966

[27.35]

828

[23.45]

966

[27.35]

Triple Stack

766

[21.69]

975

[27.61]

1254

[35.51]

1254

[35.51]

1463

[41.43]

1254

[35.51]

1463

[41.43]

Hood Ventilation Requirements

In accordance with mechanical codes, make up air must be supplied. For commercial

kitchen make up air, the amount is determined by the exhaust hood flow rate requirements and all

other exhaust flow rate requirements in the kitchen.

At a minimum, smoke candles must be used for a Capture and Containment (C&C) test.

Refer to the Ventilation Requirements disclosed in the Oven section in this manual.

A Test and Balance (TAB) report is recommended after installation has been completed.

Below are the minimum items to be included is this report:

Total airflow on all A/C, Make-Up Air (MUA), and exhaust systems.

Airflow on each supply and exhaust grille.

Airflows on exhaust hoods compared to design specifications.

A final air balance report, with any corrections of issues found in the report, will help to

insure that your building systems are functioning properly and efficiently.

NOTE: All flow rates are CFM (M

3

/Min)