Applications, 1 corrected gas volume, Corrected gas volume – Liquid Controls SP4000 User Manual

Page 16: Calculations corrected gas volume illustration, Corrected volume flow = volume flow • • • p

13

SP4000 Flow Computer

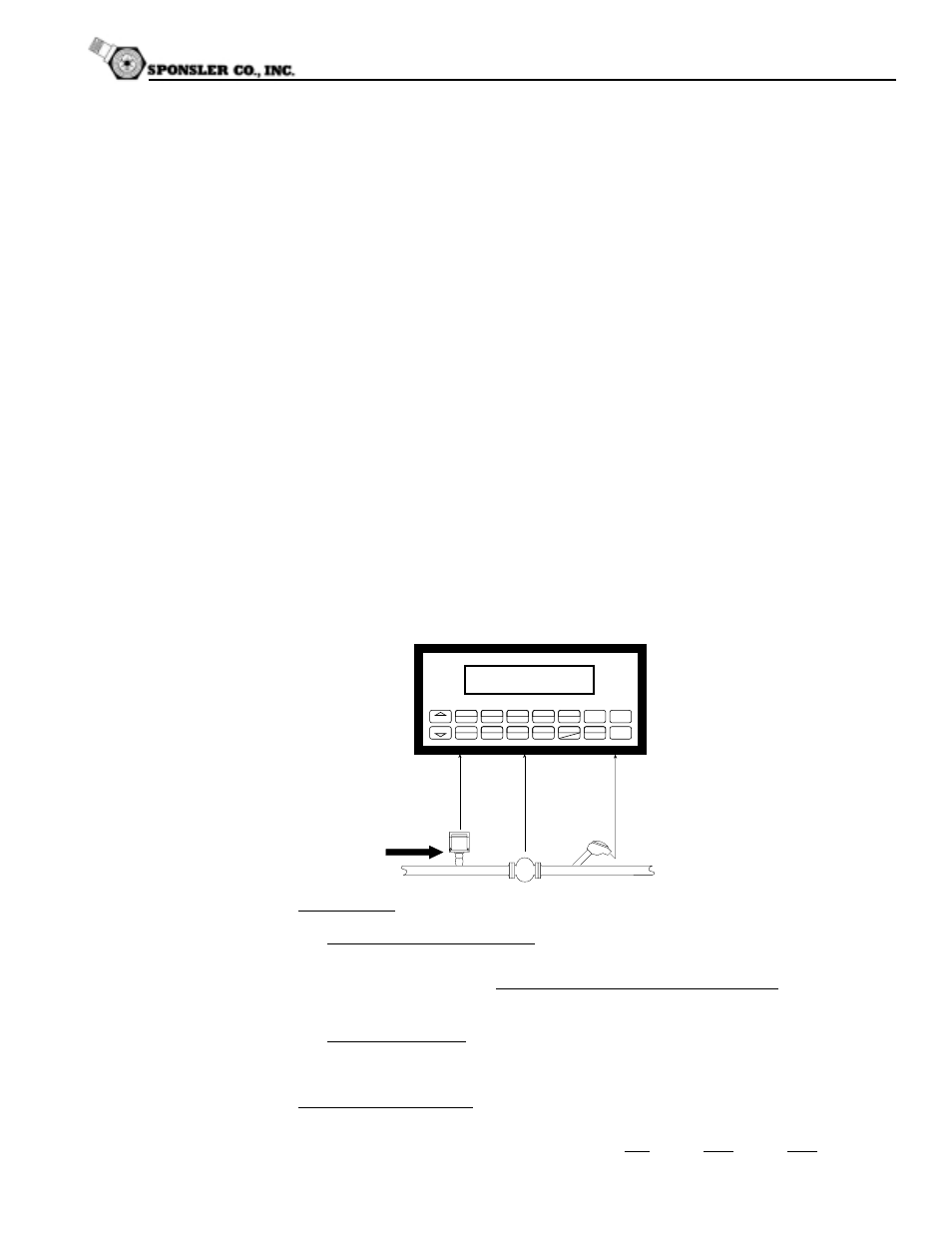

3.1 Corrected Gas Volume

Measurements:

A flowmeter measures the actual volume flow in a gas line. Temperature and pressure

sensors are installed to correct for gas expansion effects.

Calculations:

• Corrected Volume is calculated using the flow, temperature and pressure inputs as

well as the gas characteristics stored in the flow computer (see "FLUID DATA"

submenu). Use the "OTHER INPUT" submenu to define reference temperature and

reference pressure values for standard conditions.

Output Results:

• Display Results

Corrected Volume or Actual Volume Flow Rate, Resettable Total, Non-Resettable

Total, Temperature, Pressure, Density (optional: peak demand, demand last

hour, time/date stamp)

• Analog Output

Corrected Volume or Actual Volume Flow Rate, Temperature, Pressure, Density,

Peak Demand, Demand Last Hour

• Pulse Output

Corrected Volume or Actual Volume Total

• Relay Outputs

Corrected Volume or Actual Volume Flow Rate, Total, pressure, Temperature

Alarms, Peak Demand, Demand Last Hour

Applications:

Monitoring corrected volume flow and total of any gas. Flow alarms are provided via

relays and datalogging is available via analog (4-20mA) and serial outputs.

CORRECTED

GAS VOLUME

Volume Flow

Pulse Input; Average K-Factor

input frequency • time scale factor

Volume Flow =

K-Factor

Analog Input; Linear

Volume Flow = % input • Full Scale Flow

Corrected Volume Flow

P

T

ref

Z

ref

Corrected Volume Flow = Volume Flow •

•

•

P

ref

T

Z

Calculations

Corrected

Gas Volume

Illustration

Flowmeter

Temperature

Transmitter

5

0

–

TIME

CLEAR

•

MENU

ENTER

HELP

TEMP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

DENS

9

Pressure

Transmitter

3. Applications