Diagnosis and troubleshooting, 2 diagnosis flow chart and troubleshooting – Liquid Controls SP4000 User Manual

Page 115

SP4000 Flow Computer

112

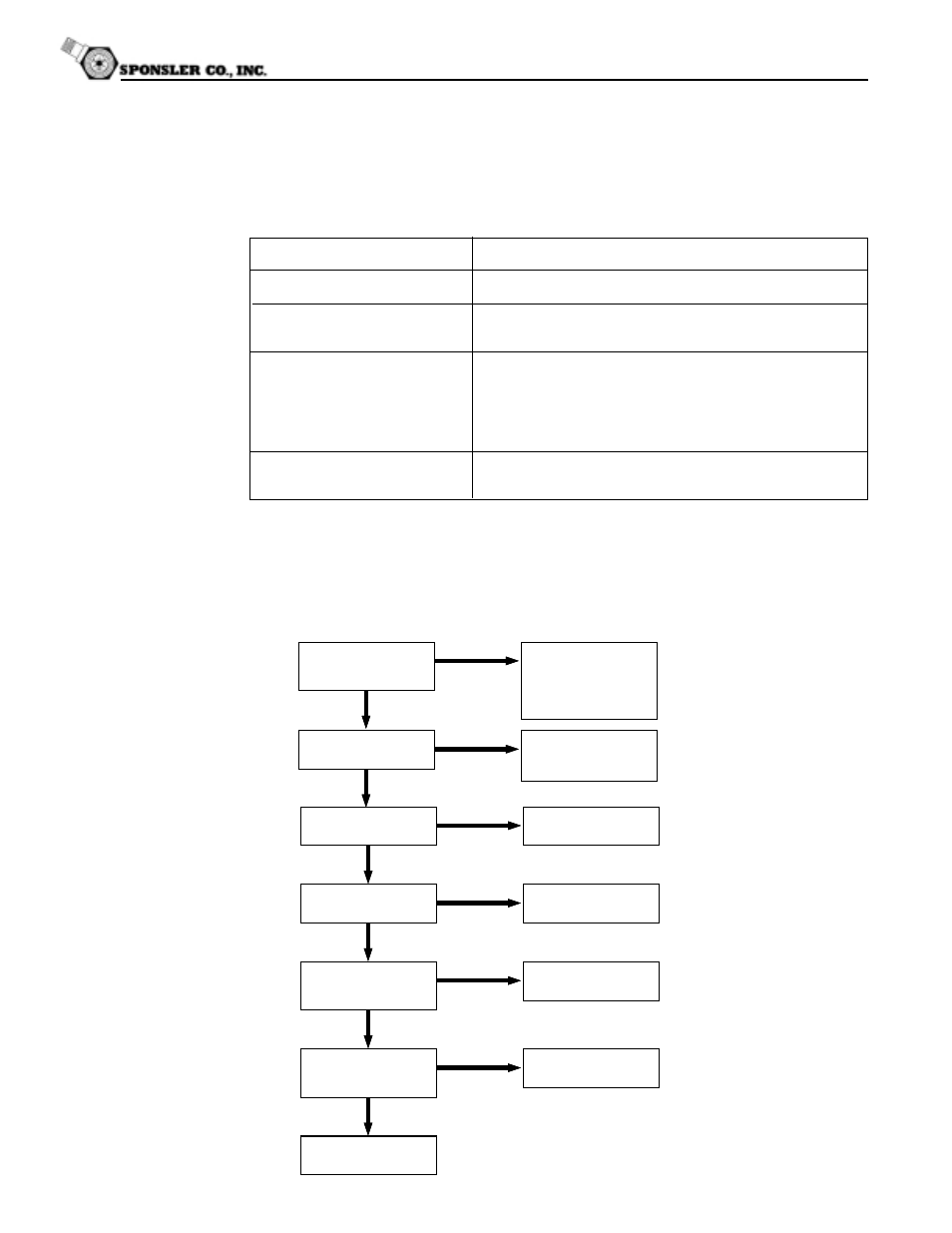

12.2 Diagnosis Flow Chart and Troubleshooting

All instruments undergo various stages of quality control during production. The last of these stages is

a complete calibration carried out on state-of-the-art calibration rigs.

A summary of possible causes is given below to help you identify faults.

Is there a power supply

voltage across Terminals

23 and 24?

No

Yes

Check the connections

according to the circuit

diagrams.

Check junction box fuses.

Is the Display Backligh

Visible?

No

Yes

Check/Replace internal

fuse. If fuse is OK,

Factory Service Required

Is there a black bar

across the display?

Yes

No

Factory Service Required

Does the display

alternate between blank

and sign on message?

Yes

No

Does the display show

an error message?

Yes

No

See section 12.3 for

cause and remedy.

No system or process

errors present.

Are the Display

Characters Visible?

No

Yes

Factory Service Required

Factory Service Required

12. Diagnosis and Troubleshooting

12.1 Response of SP4000 on Error or Alarm:

Error indications which occur during operation are indicated alternately with the measured values. The

SP4000 Flow Computer has four types of error:

TYPE OF ERROR

DESCRIPTION

System Alarms

Errors detected due to system failure

Sensor/Process Alarms

Errors detected due to sensor failure or

process alarm conditions

Service Test Errors

Errors detected due to problems found during

service test. (Service test can only be

performed by qualified Factory service

technicians because service code and special

equipment are needed)

Self Test Errors

Errors detected during self test. (Each time

the unit is powered, it runs a self test)