Figure 14 – Burkert Type 8035 User Manual

Page 29

27

Installationandwiring

Operating range

10

9

8

7

6

5

4

3

2

1

0

-15

0

+20

+40

+60

PVDF

PVDF (PN10)

PVC (PN10)

PP (PN10)

PVC + PP

11

P (bar)

T (°C)

+80

15

14

13

12

16

+100

Metal

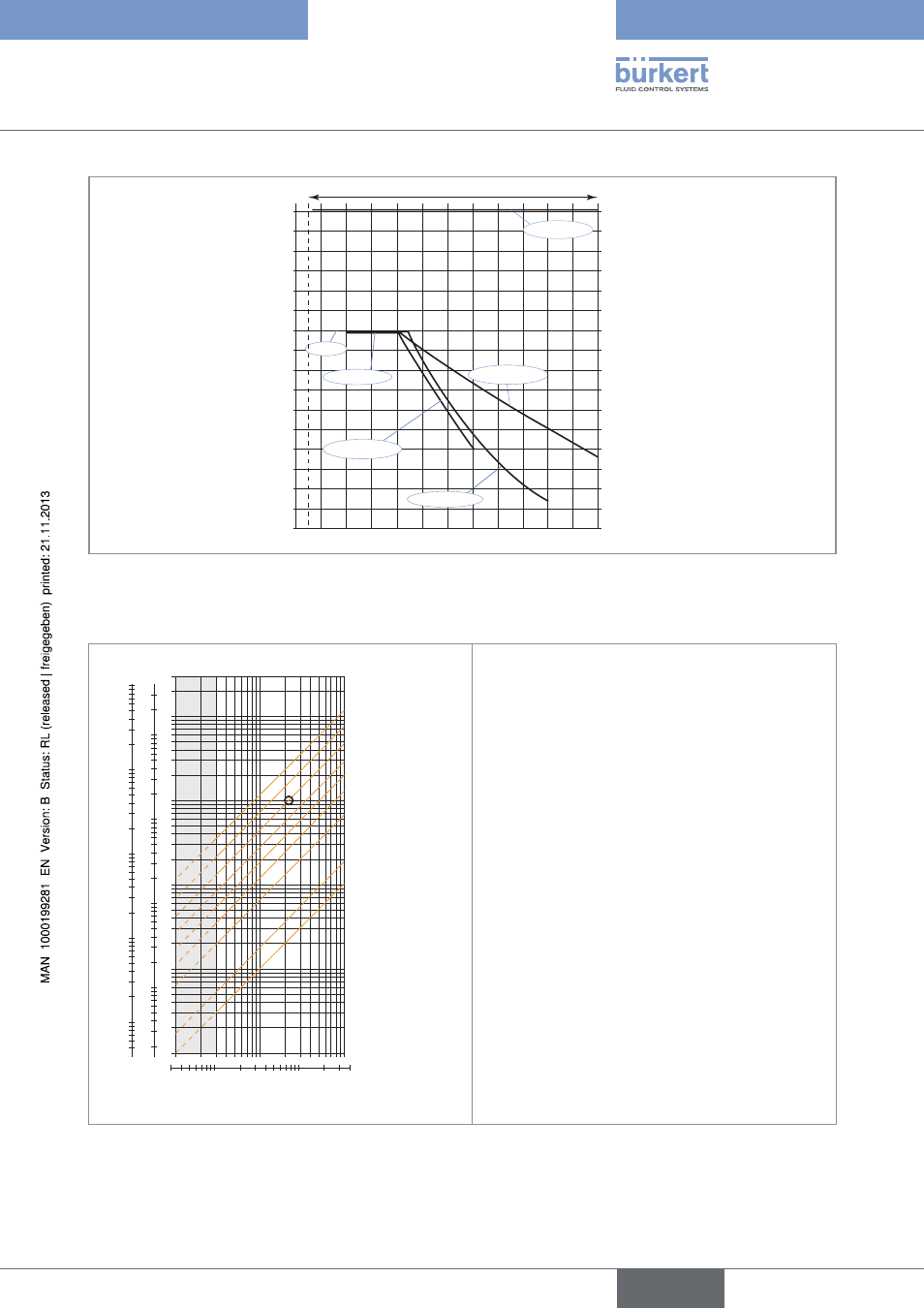

Figure 14:

Fluid pressure /temperature dependency curves for an SE35 Batch mounted on a sensor-fitting S030 in metal,

PVDF, PP or PVC

→

Choose an S030 fitting appropriate to the velocity of the fluid inside the pipe: refer to the graphs below.

0.1

0.3 0.5

1

3

5

10

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

10

20

50

100

200

m

3

/h

0.2

0.5

1

2

5

10

20

50

100

200

500

1000

2000

3000

l/min

0.3 0.5

1

3

5

10

30

m/s

fps

gpm

0.05

0.1

0.2

0.5

1

2

5

10

20

50

100

200

500

1000

DN65

DN50 (DN65)*

DN40 (DN50)*

DN32 (DN40)*

DN25 (DN32)*

DN20 (DN25)*

DN15 (DN15 or

DN20)*

DN08

DN06

Flow

rate

Fluid velocity

Example:

• Specification:

- nominal flow rate: 10 m

3

/h,

- optimum flow velocity: between 2 and 3 m/s.

• Recommended diameter: DN40 (or DN50 for the

asterisked fittings).

* For the fittings:

• with external thread connections acc. to

SMS 1145,

• with welding end connections acc. to SMS 3008,

BS 4825 / ASME BPE or DIN 11850 Rg 2,

• with Clamp connections acc. to

SMS 3017 / ISO 2852, BS 4825 / ASME BPE or

DIN 32676.

English

Type 8025 - 8035 BATCH