Xt compact conveyor xtuc s11, Recommended inspection interval, Check wear or damage of conveyor chain – FlexLink XT (макс. 30 кг) Тех. обслуживание User Manual

Page 6: 2 check the chain elongation in the idler end (d), Check the slide rails, 1 run the conveyor

2002-12-11

6

XT Compact conveyor XTUC S11

Recommended inspection interval

Inspection is recommended every 1500 operating

hours or every 3rd month depending on which case

that occurs first.

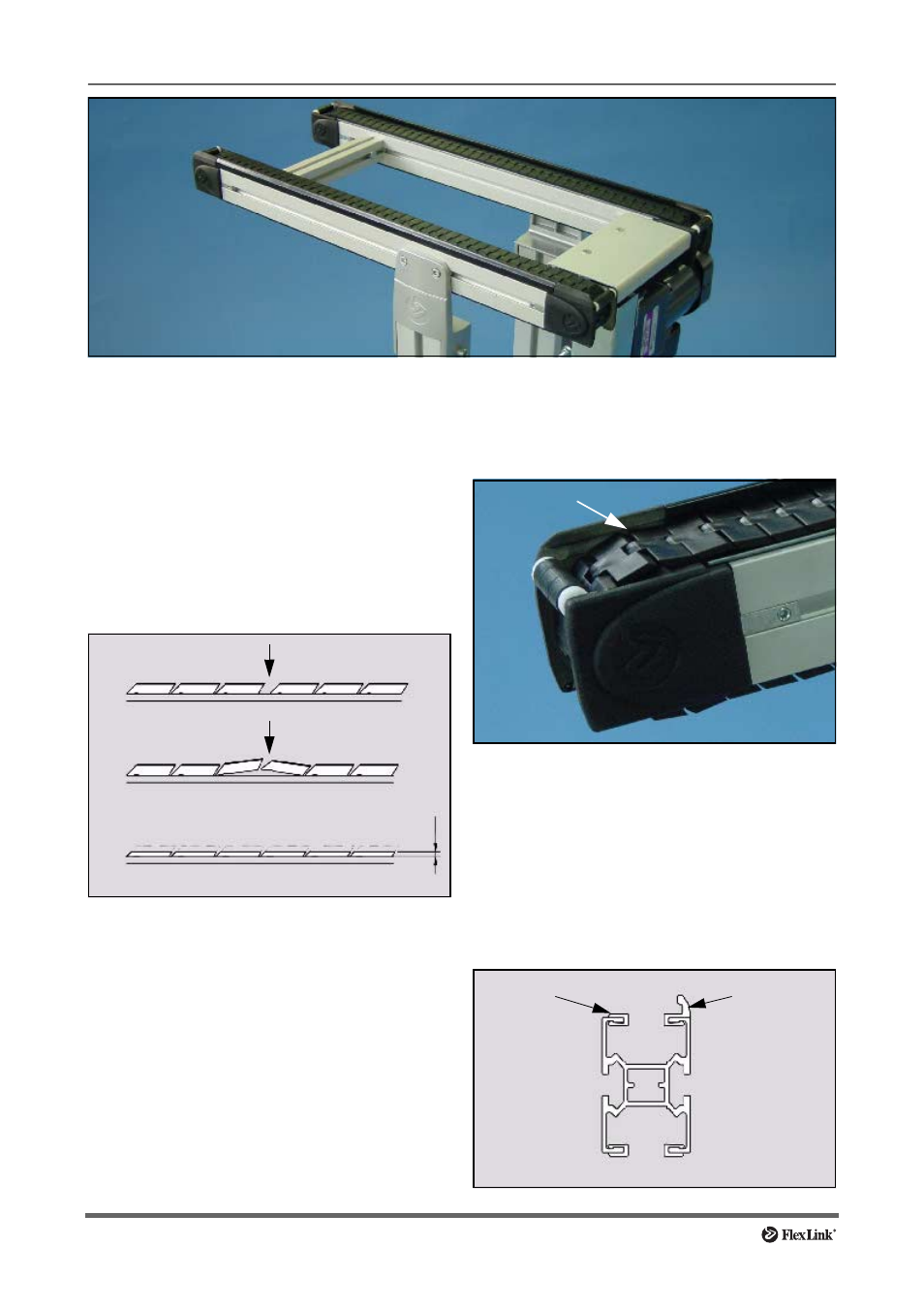

Check wear or damage of conveyor chain

1 Run the conveyor to inspect the whole chain.

Example of damage to look for is listed below:

A) Wrong chain pitch or broken top plate.

B) Non-plain chain.

C) Worn out top plates, min. thickness (t) 1 mm.

2 If any links or chain has to be replaced, see

“Replace chain on XT Compact conveyor module”

Check elongation of conveyor chain (only

valid for conveyor > 1500 mm)

1 Run the conveyor with maximum realistic amount

of loaded pallets.

Note! The higher the load the more chain tension.

2 Check the chain elongation in the idler end (D).

3 If the elongation on the conveyor chain causes a

chain slack (E), it must be shortened. Split the

chain and remove the necessary number of links,

see “Replace chain on XT Compact conveyor

Check the slide rails

1 Run the conveyor.

Irregular movement of the chain or noise may be

caused by damaged slide rail (F).

2 If you suspect damage of a slide rail try to detect

slide rail deformations (only necessary on the

upper side of the conveyor).

3 If slide rail has to be replaced, see “Replacement

A

C

B

t

D

E

F

F