FlexLink Фрикционная муфта User Manual

C. slip clutch adjustment, Introduction, Preparations for adjustment

468

C. Slip clutch adjustment

C. Slip clutch adjustment

Introduction

The slip clutch on the drive unit is a safety device which

allows the chain to stop if the load becomes excessive. It

has two purposes:

•

Prevent damage to products on conveyor

•

Prevent damage to conveyor

Note

The slip clutch is not a personal safety device. It is prima-

rily intended to protect the equipment.

Where a slip clutch is fitted, it must be adjusted so that it

does not slip whenever the drive unit is started under full

load. The installation is carried out as follows:

Preparations for adjustment

1 Stop the conveyor.

2 Ensure that the conveyor cannot be started acciden-

tally. For example: unplug the electric power plug.

3 Remove any load on the conveyor.

Caution

If you try to adjust the slip clutch when there is still load

on the conveyor, the accumulated tension in the chain

can cause severe injuries when you release the clutch.

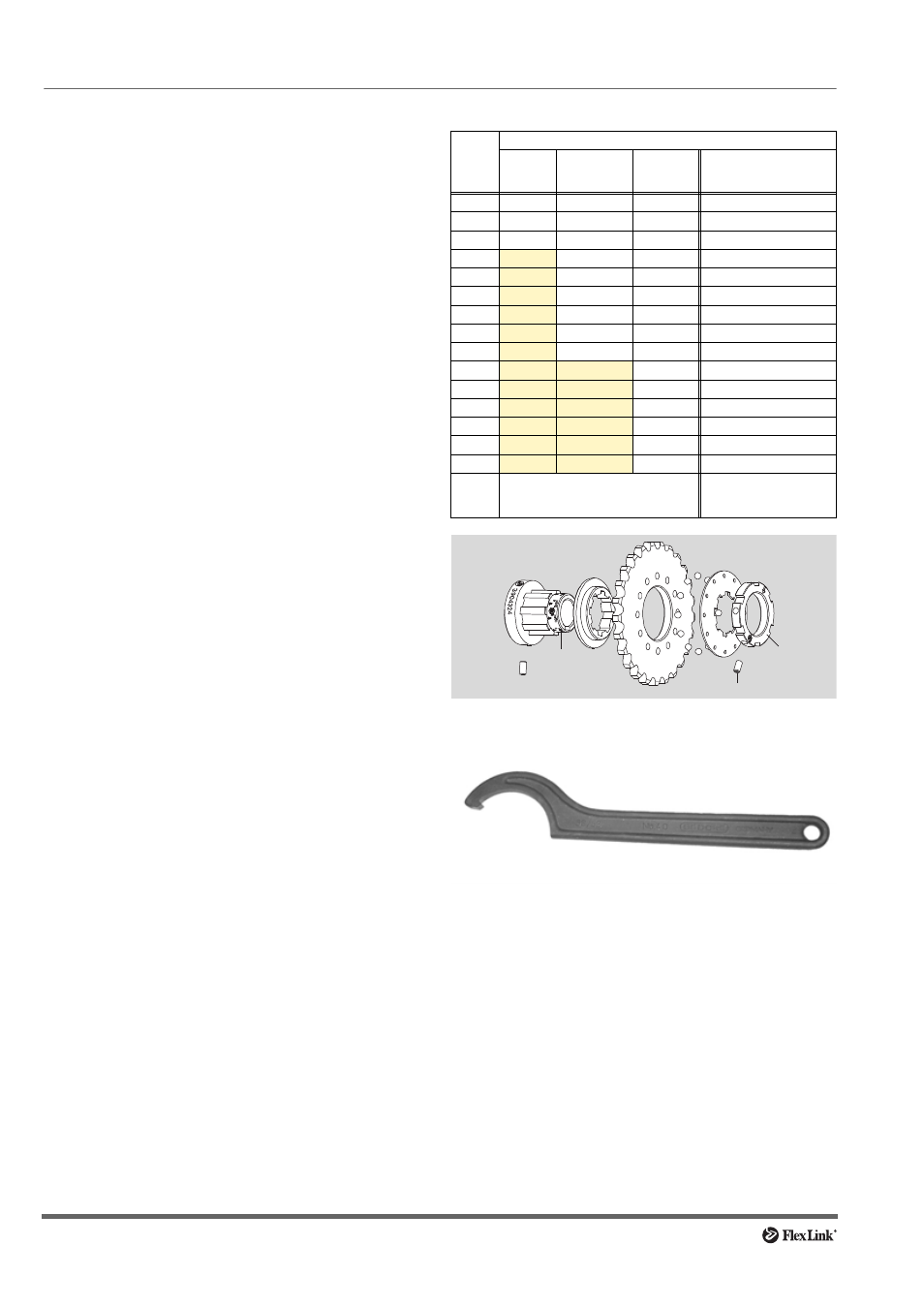

Adjustment procedure (see Figure 1)

1 Remove the drive unit protection cover.

2 Use an Allen key, 3 mm, to loosen the screw (1) on the

slip clutch so that the adjustment nut (2) can be freely

rotated.

3 Turn the adjustment nut (2) clockwise with a hook

spanner (see Figure 2) until the arrow on the nut is

aligned with the desired Fmax value (3). See Table 1

for correct values.

Note: On delivery, the clutch is always set to “0”.

4 Tighten the screw (1).

5 Re-install the drive unit protection cover.

Table 1. Adjustment of slip clutch

Figure 1. Slip clutch (exploded view)

Figure 2. Hook spanner 5053980

No.

Traction force, Fmax (N)

XS

XL

X85/XM,

XH, XK,

X180/X300

XT

XK H

0

300

300

300

600

1

400

400

400

800

2

500

500

500

1000

3

700

700

1150

4

800

800

1300

5

1550

6

1050

1050

1700

7

8

1250

1250

2000

9

10

1400

2200

11

12

1500

2400

13

14

1650

2500

Note

Standard and direct drives 1/2”:

Slip clutches marked 3904324,

5052769, 3925774, 5052827

Standard drives 5/8”:

Slip clutches marked

3925071, 5052772

1

2

3