Introduction, General introduction, Non flexlink equipment – FlexLink XT (макс. 30 кг) Тех. обслуживание User Manual

Page 4: Safety considerations, Maintenance intervals, Table 1: ready reckoner, Spare/replacement parts, Warranty/guarantee

2002-12-11

4

Introduction

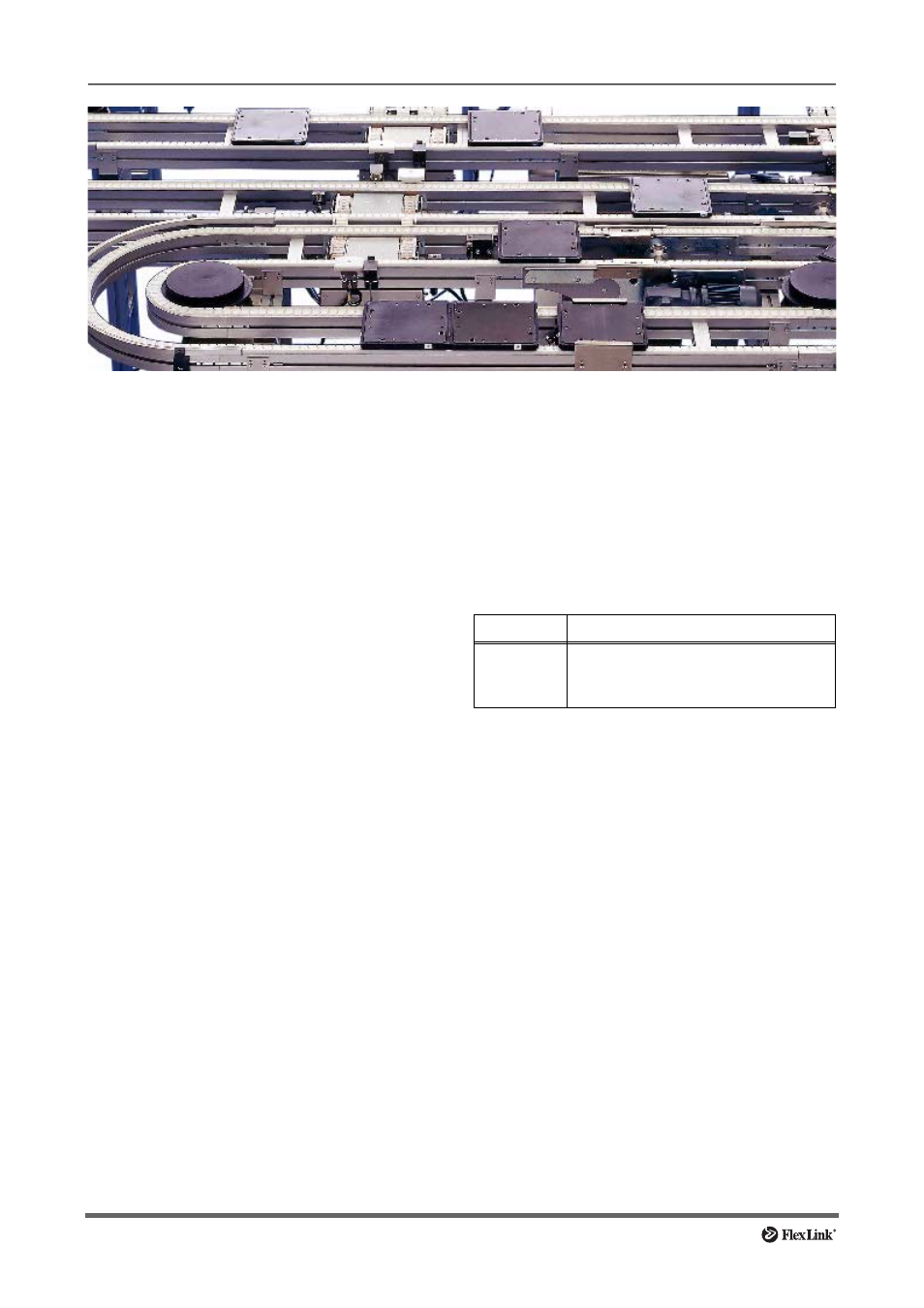

General introduction

Well-maintained equipment will ensure the life

expectancy. This manual is designed to offer

assistance for your planned maintenance schedule.

Only competent persons, who are familiar with

FlexLink equipment, should carry out maintenance of

the XT modules. If there are any doubts as to the most

suitable procedure for maintenance, consult your

FlexLink supplier.

Non FlexLink equipment

Equipment and components, which are not from the

FlexLink family of products, should be maintained and

serviced in accordance with their respective

manufacturer's instructions.

Safety considerations

Before starting any maintenance on your XT

equipment, the following safety instructions must be

observed:

• All electricity must be switched off.

• Make sure that the motor switch is also switched

off and locked in the "off" position.

• Pneumatic and/or hydraulic power must be dis-

connected and any pressure accumulation

released.

• Products being transported should, if possible, be

removed from the conveyor chain.

• Staff affected must be informed that maintenance

work is being undertaken.

Maintenance intervals

Within Assembly & Test, where XT equipment is

normally used, environmental conditions are clean

compared to many other FlexLink system installation

sites. During these conditions XT modules normally

require a minimum of maintenance.

The following maintenance interval is recommended

for XT equipment:

• Initial inspection of the chain slack is required for

all XT conveyors XTUC (type 51/52) after the first

100 operating hours.

• An inspection for all equipment is recommended

regularly every 1500 operating hours or every 3rd

month depending on which case that occurs first.

In case of less clean environmental conditions certain

wear can occur and more frequently planned

maintenance intervals are recommended. If this is the

case, consult your FlexLink supplier.

Spare/replacement parts

Check the spare parts documentation located on the

CD-Rom (FLCD-14) to identify the spare/replacement

parts required before contacting FlexLink Systems or

your supplying agent.

Warranty/guarantee

FlexLink conveyors are covered by warranties/

guarantees as identified within the trading terms

issued for each country. Check the warranty

conditions for your system before submitting claims

etc. If you are in any doubt as to what warranty is

applicable to your system, consult your supplying

agent or FlexLink Systems direct.

Table 1: Ready reckoner

Interval

1-shift

Every 3:rd month

2-shift

Every 3:rd month

3-shift

Every 1500 hours