GE Industrial Solutions AF-650 GP General Purpose Drive Programming Guide User Manual

Page 85

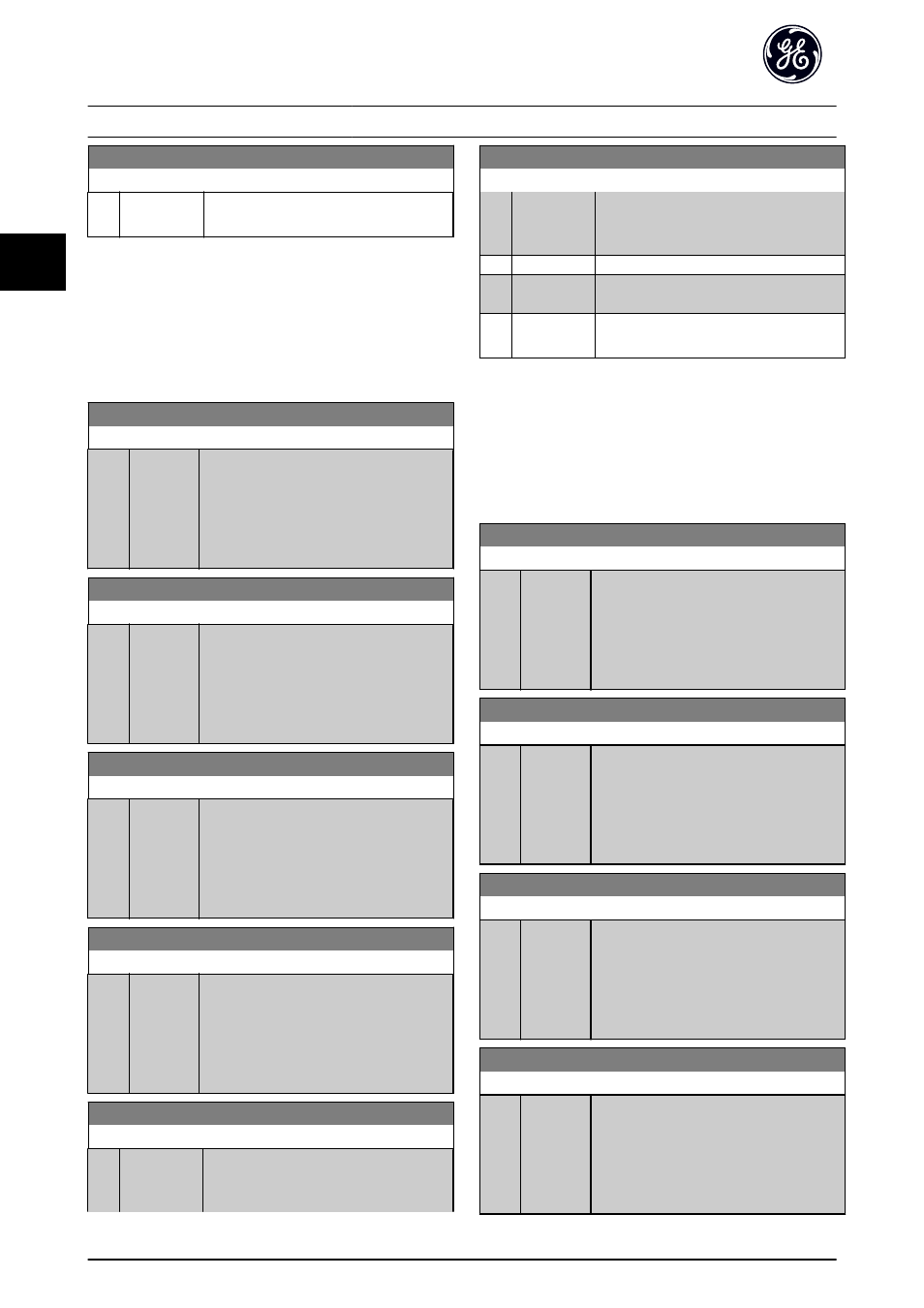

SP-76 Accel/Decel Time 2 Type

Option:

Function:

[2]

S-ramp Const

Time

S-ramp based on the values set in E-10 Accel

Time 2 and E-11 Decel Time 2

NOTE

If [1] S-ramp Const Jerk is selected and the reference during

ramping is changed the ramp time may be prolonged in

order to realize a jerk free movement which may result in

a longer start or stop time.

Additional adjustment of the S-ramp ratios or switching

initiators may be necessary.

SP-79 Accel Time 2 S-ramp Ratio at Accel. Start

Range:

Function:

50 %

*

[1 - 99 %] Enter the proportion of the total accel time

(E-10 Accel Time 2) in which the acceleration

torque increases. The larger the percentage

value, the greater the jerk compensation

achieved, and thus the lower the torque jerks

in the application.

SP-80 Accel Time 2 S-ramp Ratio at Accel. End

Range:

Function:

50 %

*

[1 - 99 %] Enter the proportion of the total accel time

(E-10 Accel Time 2) in which the acceleration

torque decreases. The larger the percentage

value, the greater the jerk compensation

achieved, and thus the lower the torque jerks

in the application.

SP-81 Decel Time 2 S-ramp Ratio at Decel. Start

Range:

Function:

50 %

*

[1 - 99 %] Enter the proportion of the total decel time

(E-11 Decel Time 2) where the deceleration

torque increases The larger the percentage

value, the greater the jerk compensation

achieved, and thus the lower the torque jerks

in the application.

SP-82 Decel Time 2 S-ramp Ratio at Decel. End

Range:

Function:

50 %

*

[1 - 99 %] Enter the proportion of the total decel time

(E-11 Decel Time 2) where the deceleration

torque decreases. The larger the percentage

value, the greater the jerk compensation

achieved, and thus the lower the torque jerks

in the application.

SP-84 Accel/Decel Ramp 3 Type

Option:

Function:

Select the ramp type, depending on

requirements for acceleration and

deceleration. A linear ramp will give

SP-84 Accel/Decel Ramp 3 Type

Option:

Function:

constant acceleration during ramping. An S-

ramp will give non-linear acceleration,

compensating for jerk in the application.

[0]

*

Linear

[1]

S-ramp Const

Jerk

Accelerates with lowest possible jerk.

[2]

S-ramp Const

Time

S-ramp based on the values set in E-12 Accel

Time 3 and E-13 Decel Time 3

NOTE

If [1] S-ramp Const Jerk is selected and the reference during

ramping is changed the ramp time may be prolonged in

order to realize a jerk free movement which may result in

a longer start or stop time.

Additional adjustment of the S-ramp ratios or switching

initiators may be necessary.

SP-87 Accel Time 3 S-ramp Ratio at Accel. Start

Range:

Function:

50 %

*

[1 - 99 %] Enter the proportion of the total accel time

(E-12 Accel Time 3) in which the acceleration

torque increases. The larger the percentage

value, the greater the jerk compensation

achieved, and thus the lower the torque jerks

in the application.

SP-88 Accel Time 3 S-ramp Ratio at Accel. End

Range:

Function:

50 %

*

[1 - 99 %] Enter the proportion of the total accel time

(E-12 Accel Time 3) in which the acceleration

torque decreases. The larger the percentage

value, the greater the jerk compensation

achieved, and thus the lower the torque jerks

in the application.

SP-89 Decel Time 3 S-ramp Ratio at Decel. Start

Range:

Function:

50 %

*

[1 - 99 %] Enter the proportion of the total decel time

(E-13 Decel Time 3) where the deceleration

torque increases. The larger the percentage

value, the greater the jerk compensation

achieved, and thus the lower the torque jerks

in the application.

SP-90 Decel Time 3 S-ramp Ratio at Decel. End

Range:

Function:

50 %

*

[1 - 99 %] Enter the proportion of the total decel time

(E-13 Decel Time 3) where the deceleration

torque decreases. The larger the percentage

value, the greater the jerk compensation

achieved, and thus the lower the torque jerks

in the application.

Parameter Descriptions

AF-650 GP Programming Guide

84

DET-618C

3

3