5 pi-5# ext. process pid ctrl – GE Industrial Solutions AF-650 GP General Purpose Drive Programming Guide User Manual

Page 138

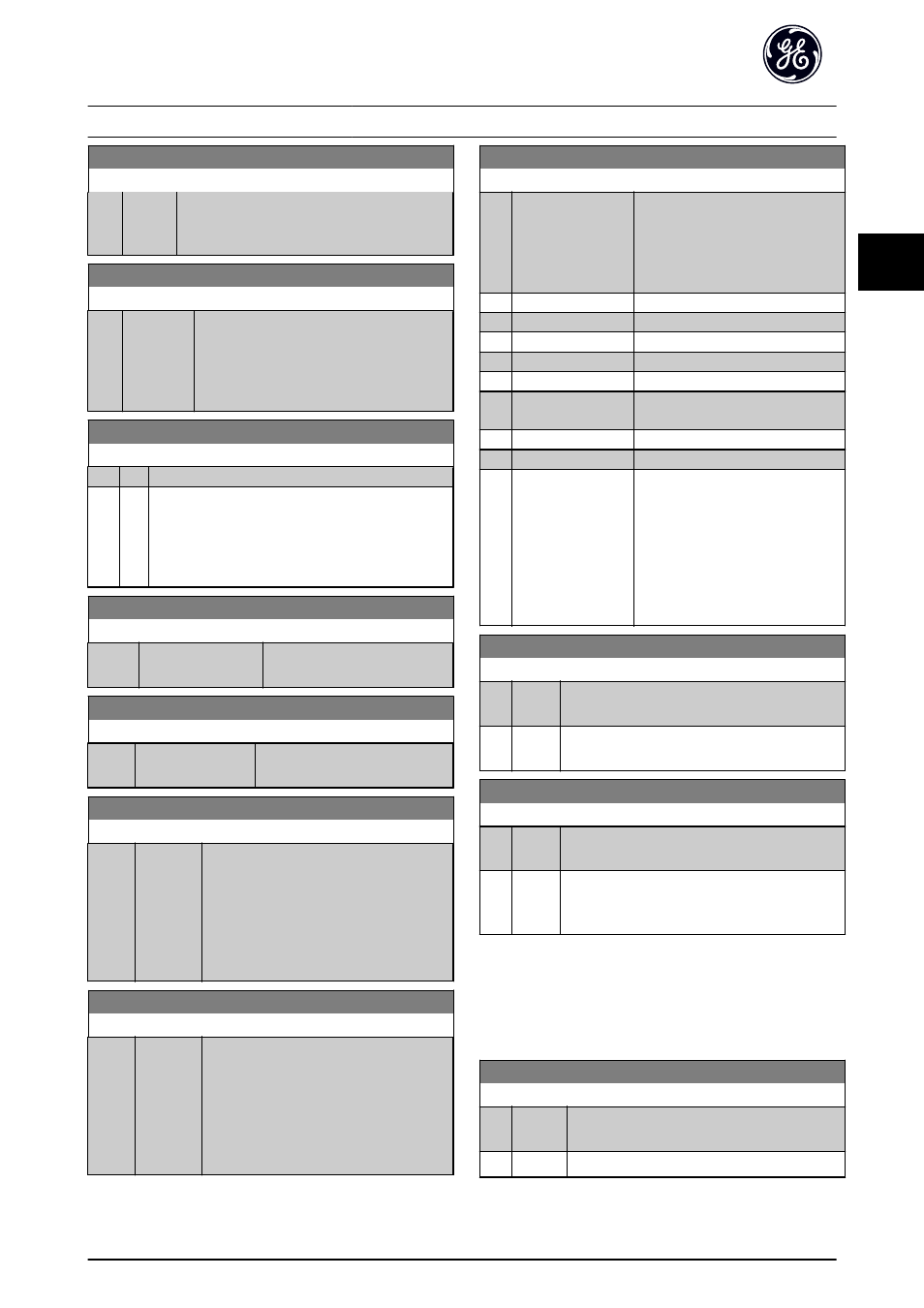

PI-38 Process PID Feed Forward Factor

Range:

Function:

PI-38 Process PID Feed Forward Factor is active

when H-40 Configuration Mode is set to [3]

Process.

PI-39 On Reference Bandwidth

Range:

Function:

5 %

*

[0 - 200

%]

Enter the On Reference bandwidth. When the

PID Control Error (the difference between the

reference and the feedback) is less than the

set value of this parameter the On Reference

status bit is high, i.e. =1.

PI-40 Process PID I-part Reset

Option:

Function:

[0]

*

No

[1]

Yes Select [1] Yes to reset the I-part of the process PID

controller. The selection will automatically revert to [0]

No. Resetting the I-part makes it possible to start from

a welldefined point after changing something in the

process, e.g. changing a textile roll.

PI-41 Process PID Output Neg. Clamp

Range:

Function:

-100 %

*

[-100 - par. PI-42 %] Enter a negative limit for the

process PID controller output.

PI-42 Process PID Output Pos. Clamp

Range:

Function:

100 %

*

[par. PI-41 - 100 %] Enter a positive limit for the

process PID controller output.

PI-43 Process PID Gain Scale at Min. Ref.

Range:

Function:

100 %

*

[0 - 100

%]

Enter a scaling percentage to apply to the

process PID output when operating at the

minimum reference. The scaling percentage

will be adjusted linearly between the scale

at min. ref. (PI-43 Process PID Gain Scale at

Min. Ref.) and the scale at max. ref.

(PI-44 Process PID Gain Scale at Max. Ref.).

PI-44 Process PID Gain Scale at Max. Ref.

Range:

Function:

100 %

*

[0 - 100

%]

Enter a scaling percentage to apply to the

process PID output when operating at the

maximum reference. The scaling percentage

will be adjusted linearly between the scale

at min. ref. (PI-43 Process PID Gain Scale at

Min. Ref.) and the scale at max. ref.

(PI-44 Process PID Gain Scale at Max. Ref.).

PI-45 Process PID Feed Fwd Resource

Option:

Function:

[0]

*

No function

Select which drive input should be

used as the feed forward factor. The

FF factor is added directly to the

output of the PID controller. This

increases dynamic performance.

[1]

Analog Input 53

[2]

Analog Input 54

[7]

Frequency input 29

[8]

Frequency input 33

[11]

Local bus reference

[20]

Digital Potenti-

ometer

[21]

Analog input X30-11

[22]

Analog input X30-12

[32]

Bus PCD

Selects a bus reference configured by

O-02 Control Word Source. Change

O-42 PCD Write Configuration for the

bus used in order to make the feed-

forward available in B-48 PCD Feed

Forward. Use index 1 for feed-

forward [748] (and index 2 for

reference [1682]).

PI-46 Process PID Feed Fwd Normal/ Inv. Ctrl.

Option:

Function:

[0]

*

Normal Select [0] Normal to set the feed forward factor to

treat the FF resource as a positive value.

[1]

Inverse Select [1] Inverse to treat the FF resource as a

negative value.

PI-49 Process PID Output Normal/ Inv. Ctrl.

Option:

Function:

[0]

*

Normal Select [0] Normal to use the resulting output from

the process PID controller as is.

[1]

Inverse Select [1] Inverse to invert the resulting output

from the process PID controller. This operation is

performed after the feed forward factor is applied.

3.21.5 PI-5# Ext. Process PID Ctrl.

This parameter group is only used if H-40 Configuration

Mode is set to [7] Extended PID speed CL or [8] Extended PID

Speed OL.

PI-50 Process PID Extended PID

Option:

Function:

[0]

Disabled Disables the extended parts of the process PID

controller.

[1]

*

Enabled

Enables the extended parts of the PID controller.

Parameter Descriptions

AF-650 GP Programming Guide

DET-618C

137

3

3