22 sf-# special functions – GE Industrial Solutions AF-650 GP General Purpose Drive Programming Guide User Manual

Page 140

3.22 SF-#

Special

Functions

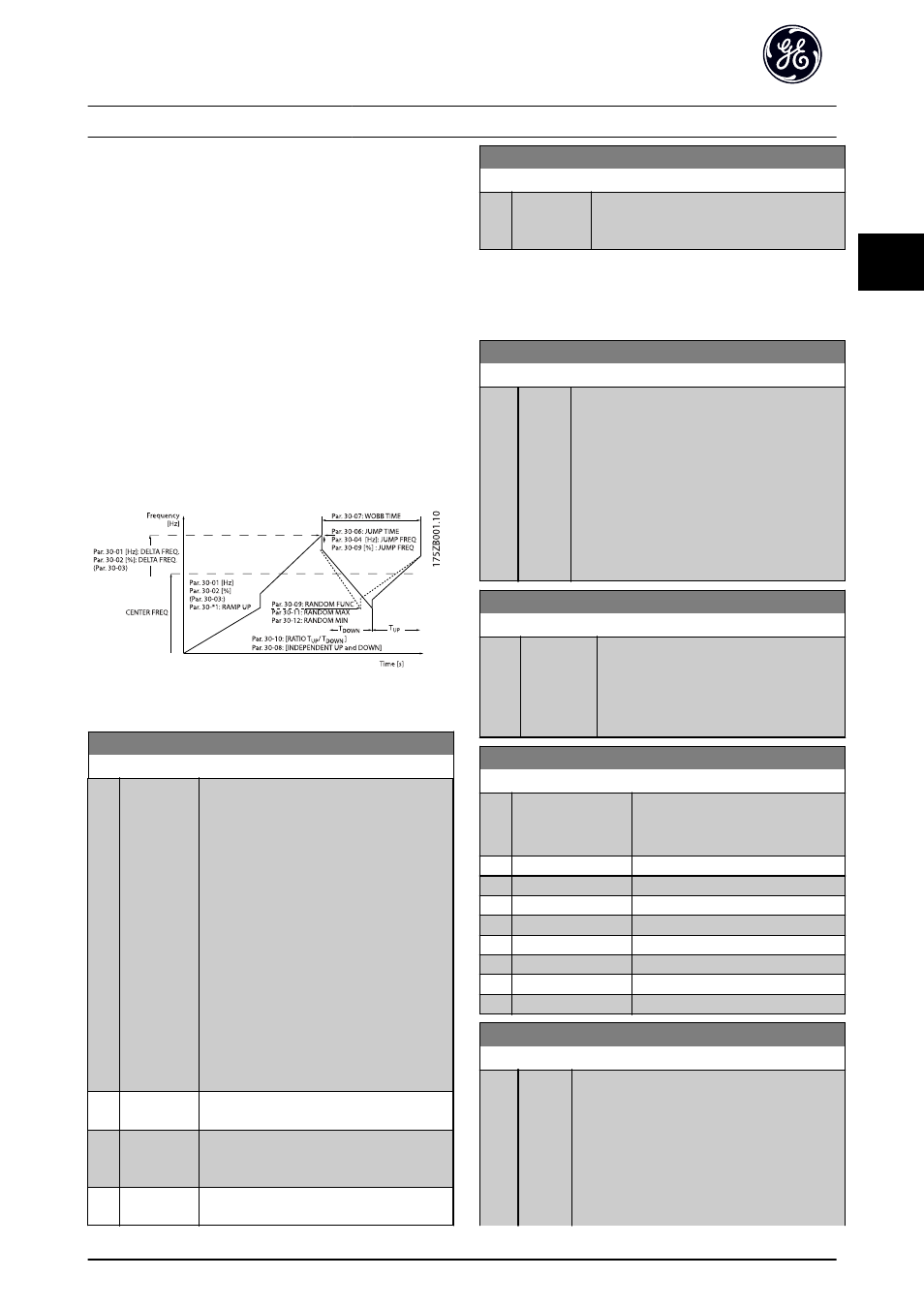

3.22.1 SF-## Wobble Function

The wobble function is primarily used for synthetic yarn

winding applications. The wobble option is to be installed

in the frequency converter controlling the traverse drive.

The traverse drive frequency converter will move the yarn

back and forth in a diamond pattern across the surface of

the yarn package. To prevent a buildup of yarn at the

same points at the surface, this pattern must be altered.

The wobble option can accomplish this by continuously

varying the traverse velocity in a programmable cycle. The

wobble function is created by superimposing a delta

frequency around a center frequency. To compensate for

the inertia in the system a quick frequency jump can be

included. Especially suitable for elastic yarn applications

the option features a randomized wobble ratio.

Illustration 3.48 Wobble Function

SF-00 Wobble Mode

Option:

Function:

NOTE

This parameter cannot be adjusted

while running.

The standard speed open loop mode in

H-40 Configuration Mode is extended with a

wobble function. In this parameter it is

possible to select which method to be used

for the wobbler. The parameters can be set

as absolute values (direct frequencies) or as

relative values (percentage of other

parameter). The wobble cycle time can be

set as an absolute alue or as independent

up- and down times. When using an

absolute cycle time, the up- and down times

are configured through the wobble ratio.

[0]

*

Abs. Freq.,

Abs. Time

[1]

Abs. Freq.,

Up/ Down

Time

[2]

Rel. Freq.,

Abs. Time

SF-00 Wobble Mode

Option:

Function:

[3]

Rel. Freq.,

Up/ Down

Time

NOTE

The setting of “Center Frequency” takes place via the

normal reference handling parameter group.

SF-01 Wobble Delta Frequency [Hz]

Range:

Function:

5 Hz

*

[0 - 25

Hz]

The delta frequency is determining the

magnitude of the wobble frequency. The delta

frequency is superimposed on the center

frequency. SF-01 Wobble Delta Frequency [Hz] is

selecting both the positive and negative delta

frequency. The setting of SF-01 Wobble Delta

Frequency [Hz] must thus not be higher than the

setting of the center frequency. The initial ramp

up time from standstill until the wobble

sequence is running is determined.

SF-02 Wobble Delta Frequency [%]

Range:

Function:

25 %

*

[0 - 100 %] The delta frequency can also be expressed

as percentage of the center frequency and

can thus be maximum 100%. The function

is the same as for SF-01 Wobble Delta

SF-03 Wobble Delta Freq. Scaling Resource

Option:

Function:

Select which drive input should be

used to scale the delta frequency

setting.

[0]

*

No function

[1]

Analog Input 53

[2]

Analog Input 54

[3]

Frequency input 29

[4]

Frequency input 33

[7]

Analog Input X30/11

[8]

Analog Input X30/12

[15]

Analog Input X48/2

SF-04 Wobble Jump Frequency [Hz]

Range:

Function:

0 Hz

*

[0 -

20.0 Hz]

The jump frequency is used to compensate for

the inertia in the traverse system. If a jump in

the output frequency is required in the top and

in the bottom of the wobble sequence, the

frequency jump is set in this parameter. If the

traverse system has a very high inertia a high

jump frequency may create a torque limit

warning or trip (warning/alarm 12) or an over

Parameter Descriptions

AF-650 GP Programming Guide

DET-618C

139

3

3