Pre-punched cards, Card quality guidelines – Datacard Group SP Series User Manual

Page 87

B-4

User’s Guide for Express™ and Select™ Printers

Pre-punched cards

You can use prepunched cards with the Express or Select printer.

shows

where punched areas are not allowed.

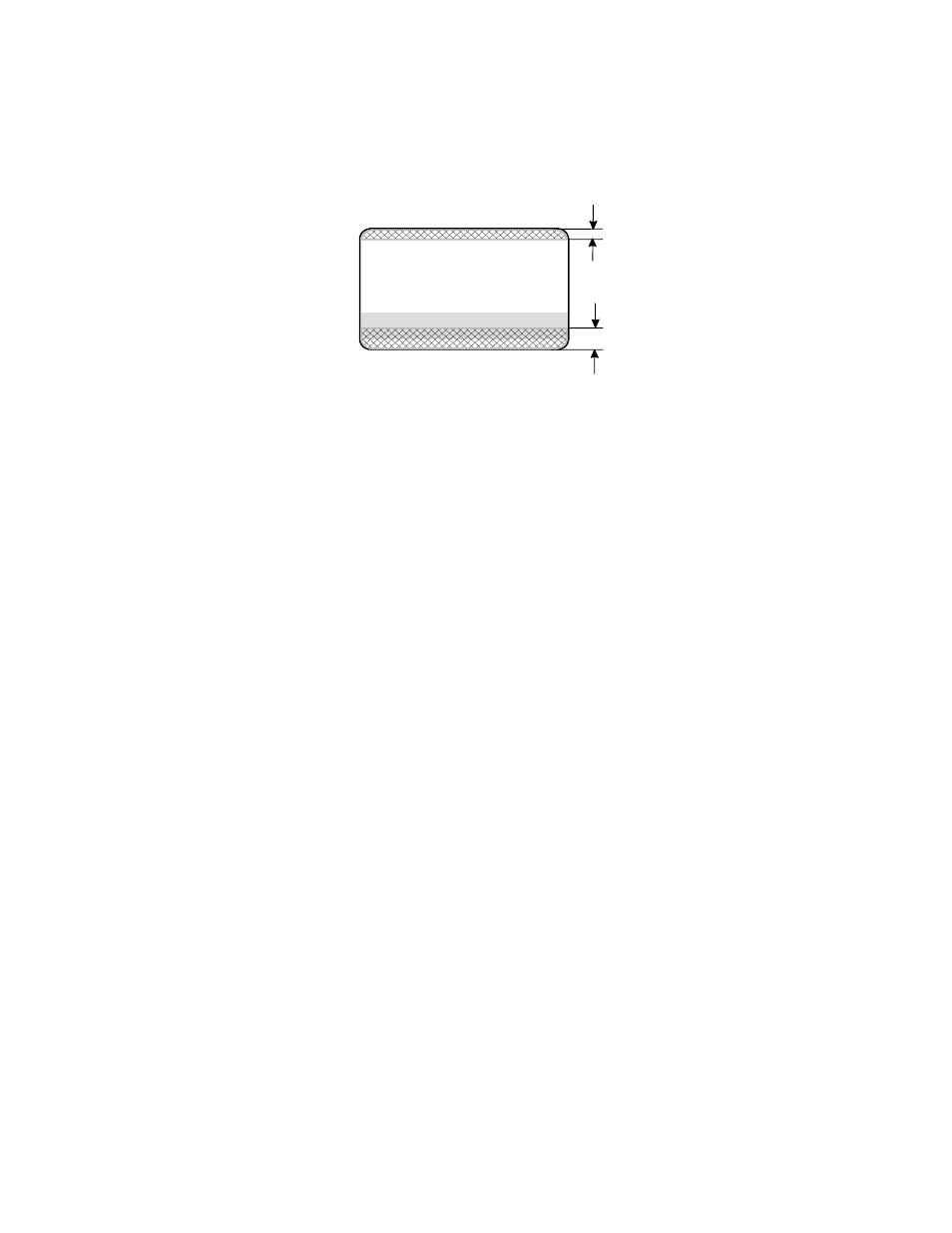

Figure B-2: Pre-punched card block-out areas

The dimensions show how far from the edge any punched areas must be (dimensions

include any tolerance):

•

The cards cannot have a punched area closer than 0.2 in (0.51 cm) from the left-

hand edge (as loaded in the card cartridge).

•

The cards cannot have a punched area closer than 0.45 in (1.14 cm) from the

right edge (as loaded in the card cartridge).

•

If the card has a magnetic stripe, the card cannot be punched anywhere in the

stripe.

Card quality guidelines

Your cards must meet the following card quality guidelines for the Express or Select

printer to print high quality graphics on them successfully.

Card surface

•

The card surface must be free of irregularities such as particles embedded in the

surface.

•

The card surface must be smooth and even. Surface irregularities can cause loss

of contact, resulting in printing voids.

•

The printing surface must be glossy. It cannot have a matte finish (see other

sections in this appendix for more information).

Card handling

These guidelines apply to unprinted cards. Any debris or particles on an unprinted

card’s surface can reduce print quality and damage the printhead. Grease or oils,

such as oils from your fingers, also reduce print quality.

•

Keep cards completely clean.

•

Do not touch the print surface of a card with your fingers or hands.

•

Do not use a rubber band to bind blank cards together.

0.2 in (0.51 cm)

0.45 in (1.14 cm)

Magnetic stripe on back