Hale 5.0 FoamLogix User Manual

Page 87

ΙΙΙ

-7

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

III

: Set-up and Calibration

WATER FLOWSENSOR CALIBRATION

NOTE: The flowsensor is calibrated at

Hale Products Inc. and matched to the

control unit. If the system is installed

properly only minor adjustments should

be necessary to flowsensor reading.

Flowsensor calibration should be verified

during NFPA/UL testing of apparatus and

delivery to end user.

NOTE: An accurate flow measuring

device must be used to measure the

water flow when calibrating the

flowsensor. Use a suitable size smooth

bore nozzle and an accurate Pitot

Gauge instrument. Hand held pitot

gauges are usually not very accurate.

Make sure the system is calibrated with

an accurate flow measuring device.

Determine the water flow normally

expected from the discharge outlet and

establish flow. Make sure the water flow

established is within the range of the

flowsensor monitoring the discharge. For

example, actually establish a flow of 150

GPM (568 LPM) of water through a nozzle

and Pitot system. Compare the calculated

flow value to the value shown on the

control unit digital display.

Press the

é or ê button to set the reading

to match the actual flow calculated from

the Pitot gauge reading. Decrease fire

pump pressure by approximately ½ and

recalculate water flow rate. Verify the

reading on the control unit is within 5% of

the actual value. Stop the water flow when

the reading adjustments are completed.

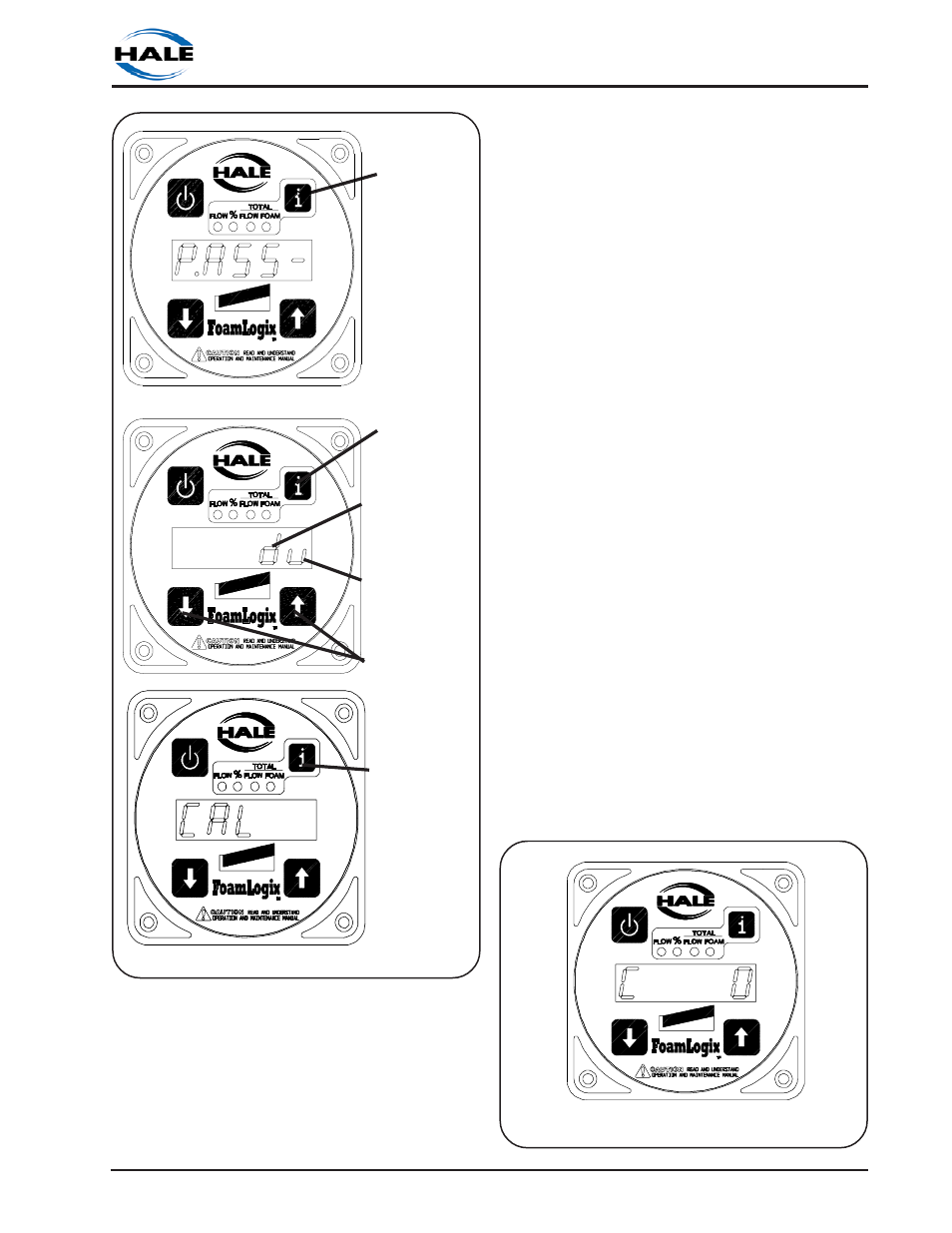

Figure 3-4. Flowsensor Calibration Display

Figure 3-3. Entering Calibration Mode

RELEASE WHEN

DISPLAY SHOWS

"CALIB"

PRESS AND

HOLD

CONTINUE TO

HOLD

DISPLAYS WHEN

ê

IS PRESSED

DISPLAYS WHEN

é

IS PRESSED

PRESS IN

SEQUENCE AS

NECESSARY TO

ENTER

PASSWORD