System installer start-up – Hale 5.0 FoamLogix User Manual

Page 76

ΙΙ

-46

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

INITIAL SYSTEM POWER CHECK

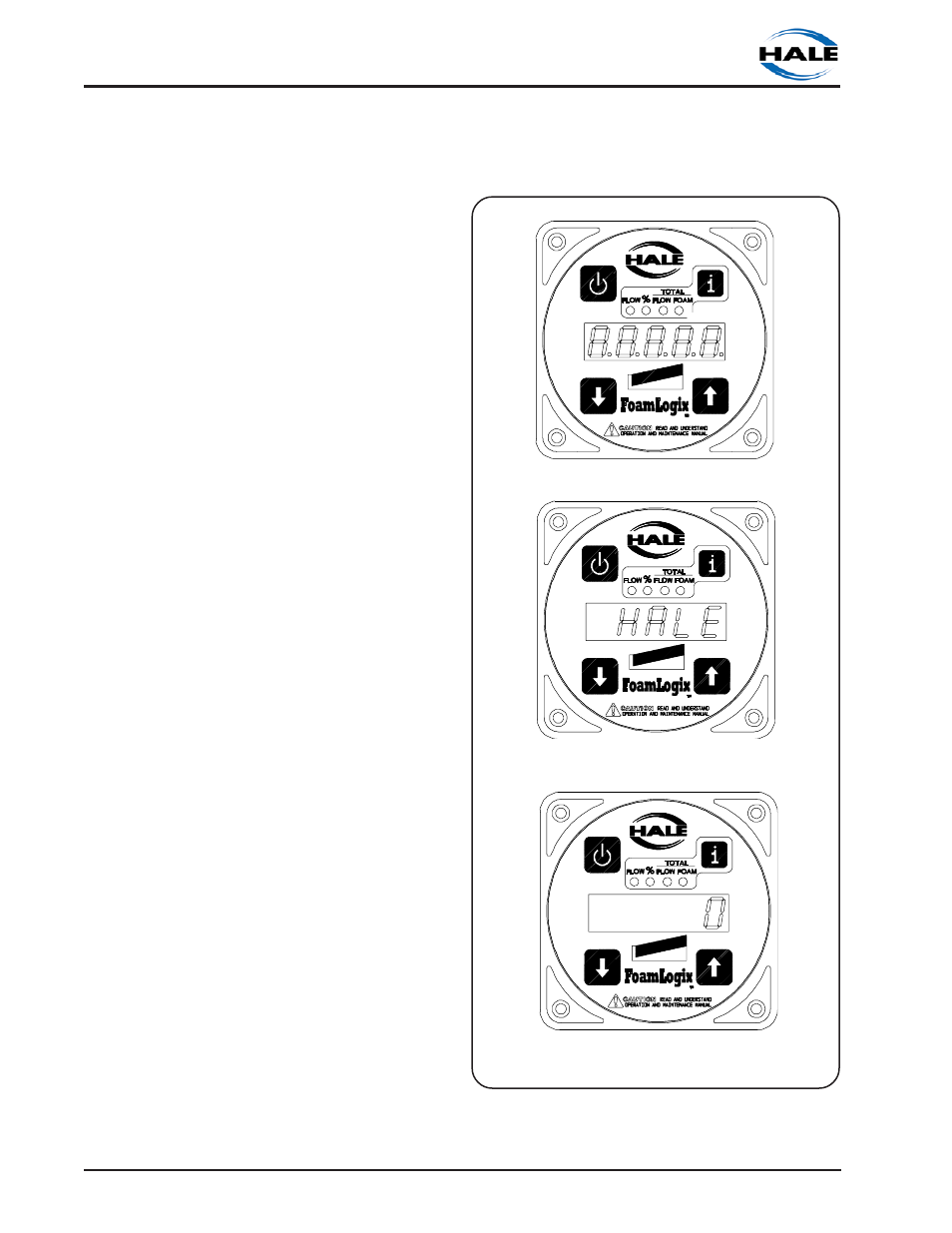

Observe the display on the control unit

while energizing the apparatus electrical

system and turn the foam pump distribution

box power switch to ON. Check the control

unit readout — FLOW, TOTAL FLOW, %

FOAM, TOTAL FOAM and all bargraph LEDs

will light along with

"88888"

for several

seconds. "

HALE

CLASS 1 2002" will scroll

across the display while the system checks

itself followed by the default display. The

default display is zero on the digital readout

(if no water is flowing) and FLOW LED (See

figure 2-32). If default display does not

appear refer to TROUBLESHOOTING for

possible causes and solutions.

INITIAL SYSTEM OPERATION CHECK

After initial system power-up, low tank level

sensor operation, foam pump operation

and flowsensor calibration must be

checked. Use the following procedures to

complete these system checks.

CAUTION: Water is used at the system

installer facility to verify low tank level sensor

operation and foam pump operation as the

end user specified foam concentrates may

not be readily available. DO NOT pump

water with the Hale FoamLogix foam pump

for more than one minute per foam tank.

DO NOT attempt to calibrate foam pump

feedback sensor with other than end user

specified foam concentrate. Make sure the

bypass valve is in the BYPASS position when

pumping water with the foam pump.

1. Upon initial power-up with the foam

tanks empty the display on the control

unit will alternate between "

0

" and "

Lo A

"

indicating the foam tank is empty. Fill

foam concentrate tank A with water.

The "

Lo A

" indication should disappear

from the control unit display indicating

the low tank level sensor in Tank A is

operating properly.

When energizing the Hale FoamLogix system at the system installer facility for the first time

the following procedures shall be used.

Figure 2-32. Control Unit Ready Indication

WARM-UP/SYSTEM CHECKING

SYSTEM READY

SYSTEM INSTALLER START-UP

INITIAL POWER-UP