Saddle clamp installation, Ιι -14 – Hale 5.0 FoamLogix User Manual

Page 44

ΙΙ

-14

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

on the flowsensor outlet. In the short length

of reduced pipe pressure loss will be

minimal and there will be minimal pressure

loss through elbows and fittings. Figure 2-9

shows a typical reduced piping run

installation.

Excessive turbulence in the flowsensor may

produce unstable and inaccurate flow

readings. The length of straight pipe prior to

the flowsensor must be sufficient to reduce

the turbulence in the pipe. The following

installation guidelines will help attain the

best readings, and maintain the accuracy

of the Hale FoamLogix system.

a. A minimum 6 times the pipe diameter

of straight run pipe without any fittings is

necessary prior to the flowsensor

paddlewheel (see figure 2-10). Minimum

required straight pipe run:

e

z

i

S

e

p

i

P

d

e

d

n

e

m

m

o

c

e

R

m

u

m

i

n

i

M

e

p

i

P

n

u

R

t

h

g

i

a

r

t

S

)

m

m

8

3

(

.

n

i

½

-

1

)

m

m

1

9

1

(

.

n

i

9

)

m

m

0

5

(

.

n

i

2

)

m

m

4

5

2

(

.

n

i

2

1

)

m

m

4

6

(

.

n

i

½

-

2

)

m

m

7

1

3

(

.

n

i

5

1

)

m

m

6

7

(

.

n

i

3

)

m

m

1

8

3

(

.

n

i

8

1

)

m

m

2

0

1

(

.

n

i

4

)

m

m

8

0

5

(

.

n

i

4

2

b. The downstream piping length is not

as critical but there should be a short

length of straight pipe with no fittings or

valves immediately after the flowsensor

paddlewheel.

c. Do not mount a flowsensor directly

after an elbow or valve. Valves create

severe turbulence when they are

“gated”.

SADDLE CLAMP INSTALLATION

Installation of the Paddlewheel Flowsensor

using a saddle clamp requires a 1.385/1.390

inch bored hole in the pipe. A minimum of

six times the pipe diameter of straight run

pipe without any fittings is necessary prior to

the position of the hole.

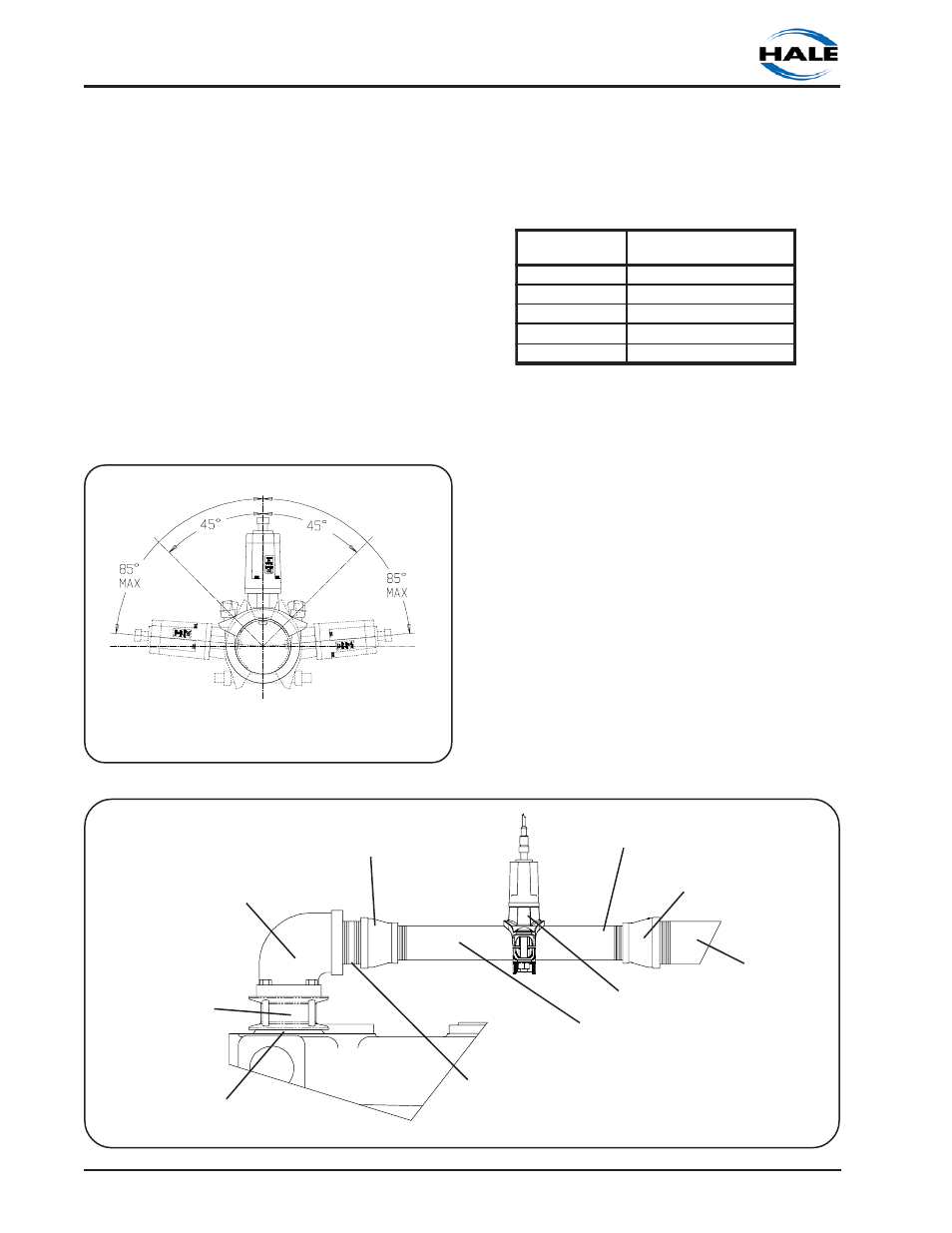

Figure 2-9. Typical Reduced Flowsensor Piping Arrangement

Figure 2-8. Flowsensor Tee Position Range

in Horizontal Piping Runs

HALE 2H98 ELBOW

2-½ INCH NPT

OUTLET

2-½ INCH X 2 INCH

NPT REDUCER

2-½ INCH

DIAMETER PIPE

2-½ INCH NPT

CLOSE NIPPLE

2 INCH DIAMETER

PIPE NIPPLE

MINIMUM 10 INCHES LONG

2 INCH DIAMETER PIPE

NIPPLE

2-½ INCH X 2 INCH

NPT REDUCER

HALE 3 INCH

CHECK VALVE

MIDSHIP PUMP

CONNECTION

HALE HPF 20

FLOWSENSOR