Hale 5.0 FoamLogix User Manual

Page 46

ΙΙ

-16

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

to making connections.

NOTE: Foam concentrate gravity fed.

FOAM STRAINER

IN-LINE STRAINER/VALVE ASSEMBLY

CAUTION: The in-line strainer/valve

assembly is a low pressure device and

WILL NOT withstand flushing water

pressure. When installing the in-line

strainer in systems equipped with Hale

MDT

ΙΙ

or Hale MST make sure the in-line

strainer/valve assembly is in the hose on

the inlet side of the valve. If the strainer

will be subject to flushing water pressure,

use Hale FS series strainers.

The in-line strainer/valve assembly has 1-1/4

inch NPT female threaded ports. Fittings are

supplied for connection of ¾ inch (19 mm),

1 inch (25 mm) or 1-1/4 inch (32 mm) inside

diameter hose depending on the viscosity

of foam concentrates used. (See figure 2-

12) Generally ¾ inch inside diameter hose

will be used for Class A foam and 1 inch

inside diameter hose will be used for Class B

foams. For high viscosity Class B foam

concentrates it may be necessary to use 1-

1/4 or 1-1/2 inside diameter hose. A

bracket is included with the in-line strainer/

valve assembly to permit installation on the

apparatus.

The hose from the foam tank(s) to the

strainer should have adequate wall stiffness

to withstand the vacuum of the foam pump

while it is operating [23 inches (584 mm) Hg

and 50 PSI (3 BAR)] (Kuriyama, Kuri-tec K-

7130 series or equal).

The following procedures are provided for

installation of the in-line strainer/valve

assembly:

1. Choose a location on the apparatus

that allows gravity feed from the foam

tank to the strainer inlet and from the

strainer outlet to the foam pump suction

connection.

NOTE: When selecting the strainer

location make sure there is sufficient

space below the strainer for removal of

the strainer basket and screen for

cleaning. A minimum of 5 inches (127

mm) is required for this purpose. Also

make sure there is at least 2 inches (51

mm) above the strainer assembly to

permit operation of the service valve.

(Refer to figure 2-12)

2. Refer to the diagram in figure 2-13 and

mark 4 holes for mounting the foam

strainer bracket. The holes must be

drilled to accommodate ¼-20 UNC

screws. The holes can either be tapped

(#7 drill for ¼-20 UNC tap) or drill large

enough to use screws, nuts and washers

(9/32 inch (7 mm) diameter) to secure

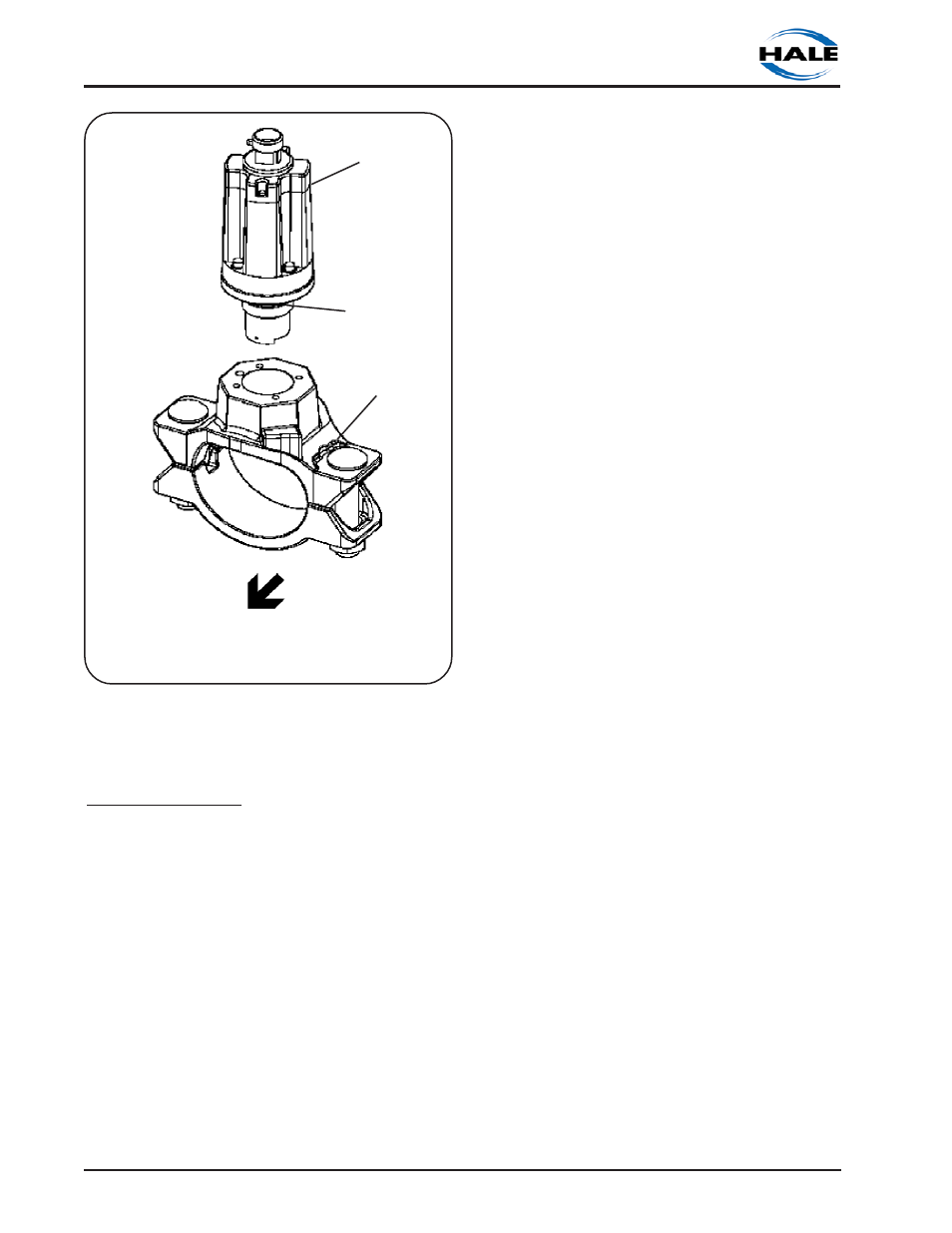

Figure 2-11. Flowsensor Sensor Service

WATER FLOW DIRECTION

SADDLE CLAMP

O-RINGS

SENSOR