Hale 5.0 FoamLogix User Manual

Page 67

ΙΙ

-37

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

1. Using dimensions in figure 2-27, layout

and drill holes in the top of the foam

tank. The center of the sensor should be

located at least 1-½ to 2 inches (38 to 51

mm) from the sides of the foam tank.

NOTE: The minimum depth of foam tank

for installation of the top mount sensor

without cutting the tube sections is 31-½

inches (800 mm). If the tank depth is less

than 31-½ inches (800 mm) cut the

tubing as described in step c.

2. Determine the approximate length of

the top mount low tank sensor extension

by measuring from the top of the foam

tank at the flange opening to the

bottom of the tank. When properly

installed the center of the sensor float

should be 1-½ to 2 inches (38 to 51 mm)

above the bottom of the foam tank.

3. Slide the flange to the top of the 5/8

inch diameter tube and adjust the

telescoping section until the desired

length is achieved as measured from

the bottom of the flange to the bottom

of the sensor. Tighten the compression

fittings on the union to lock length.

CAUTION: Use mounting hardware that

is compatible with all foam

concentrates to be used in the system.

Use washers, lockwashers and

capscrews made of brass or 300 series

stainless steel.

4. Insert sensor assembly through the

1.31 inch (33 mm) hole and align the

screw holes on the flange and gasket

with the holes on the tank. Secure the

assembly in place using four ¼-20 UNC x

1 inch long cap screws, ¼ inch washers

and ¼ inch lockwashers.

5. Make final adjustment to the sensor

position by pulling the tubing sections up

through the flange until sensor is 1-½ to 2

inches (38 to 51 mm) from the bottom of

the tank. Tighten the 5/8 tube

compression nut on the flange.

6. Close strain relief to the 90

0

position

making sure it snaps shut. Tighten strain

relief gland nut to seal out water and

contamination.

RESIZING THE LOW LEVEL SENSOR

Some applications may require the top

mounted sensor to be shorter than

factory length. Use the following

procedure only if the tube sections are

too long otherwise proceed to step d.

Refer to figure 2-28, disassemble and cut

the tube sections as follows:

1) Loosen and remove the

3

/

8

FNPT x

5

/

8

tube fitting and strain relief from the top

of the sensor assembly. Carefully slide

the sensor wire out of the strain relief

gland.

2) Loosen and remove the ¼ FNPT x ½

tube fitting and sensor from the bottom

of the sensor assembly. DO NOT remove

the ½ inch tube from the

5

/

8

inch tube.

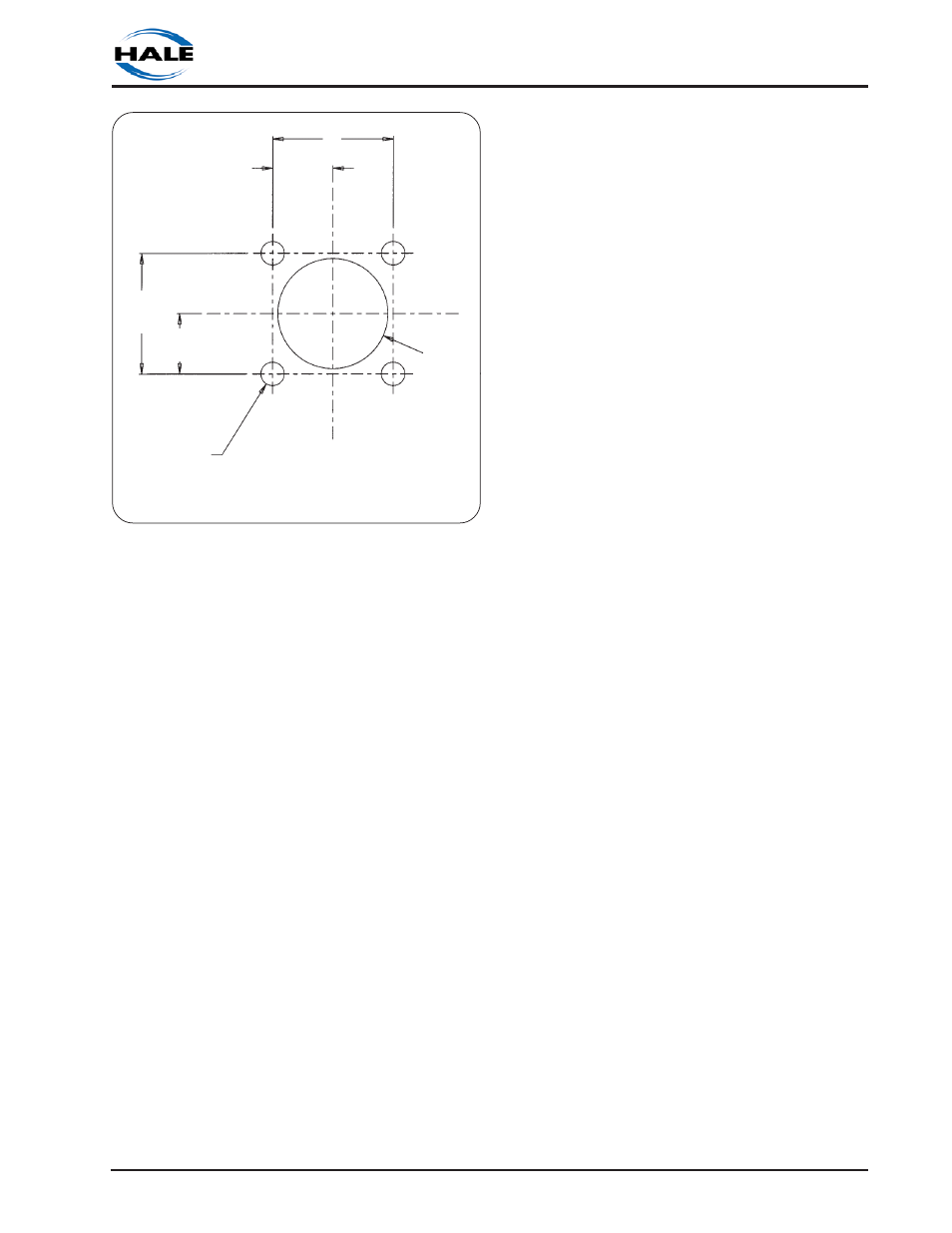

Figure 2-27. Top Mount Low Tank Switch

Mounting Flange Cutout Dimensions

1.44 in.

(37 mm)

0.72 in.

(18 mm)

(4) Thru Holes

0.281 in. (7 mm)

1.31 in.

(33 mm)

Dia. Thru

Hole

0.72 in.

(18 mm)

1.44 in.

(37 mm)