Hale 5.0 FoamLogix User Manual

Page 69

ΙΙ

-39

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

DUAL FOAM TANK SYSTEM

When the Hale FoamLogix system is installed

using a Hale ADT or Hale MDT

ΙΙ

connect

the low tank level sensors using the following

procedure (refer to figure 2-29):

CAUTION: Before running wires from the

low tank switches to the A-B switch box

make sure the wire from Tank A is

identified and properly labeled.

1. Using minimum 16 AWG Type SXL or

GXL (SAE J1128) wire, extend the pigtails

on the low tank level sensors to the A-B

switch box. When making splices to

extend the low tank sensor wires make

sure the splices are sealed using an

adhesive filled heat shrink tubing. Where

two wires exit the heat shrink tubing

pinch the tubing while heating the

tubing to make sure the adhesive seals

around both wires.

CAUTION: Use the silicone sealer

provided with the Hale FoamLogix

system to insulate the terminal strip

connection screws and prevent

corrosion.

2. Tie one wire from each low level

switch together as a common lead.

Connect this common lead to the

center screw on the terminal block on

the A-B switch box.

3. Connect the lead from Tank A to the

terminal labeled A TANK on the switch

box and connect the wire from Tank B to

the terminal labeled B TANK.

4. Seal the terminal strip connections

using the silicone sealer provided.

DISPLAY UNIT POWER AND GROUND

CONNECTIONS

Power must be connected directly to

the display unit. The power and ground

connection is the 2 pin packard

connector on the 12 inches long pigtail

on the flow sensor harness (see figure 2-

24). The mating harness provided is

approximately 18 inches long. If

additional wire length is required, use

minimum 16 AWG type SXL, or GXL (SAE

J1128) wire.

Using the harness provided, connect the

black (B) wire to a chassis ground stud.

Protect the ground connection from

corrosion.

Connect the red (A) wire to the power

supply. Idealy this power wire should be

connected to a minimum 5 AMP fused

dedicated circuit. If a dedicated circuit

is not available then the power lead can

be connected to a terminal where there

is not a high current load. Acceptable

additional components powered from

this terminal include ENFO IV, Governor,

Tank Level Gauge, Etc.

DISTRIBUTION BOX GROUND AND

PRIMARY POWER CONNECTIONS

CAUTION: Connect the primary positive

lead from the terminal block to the

master switch terminal or relay terminal

using minimum 4 AWG type SGX (SAE

J1127) chemical resistant battery cable

and protect with wire loom.

CAUTION: Prevent corrosion of power

and ground connections by sealing

these connections with silicone sealant

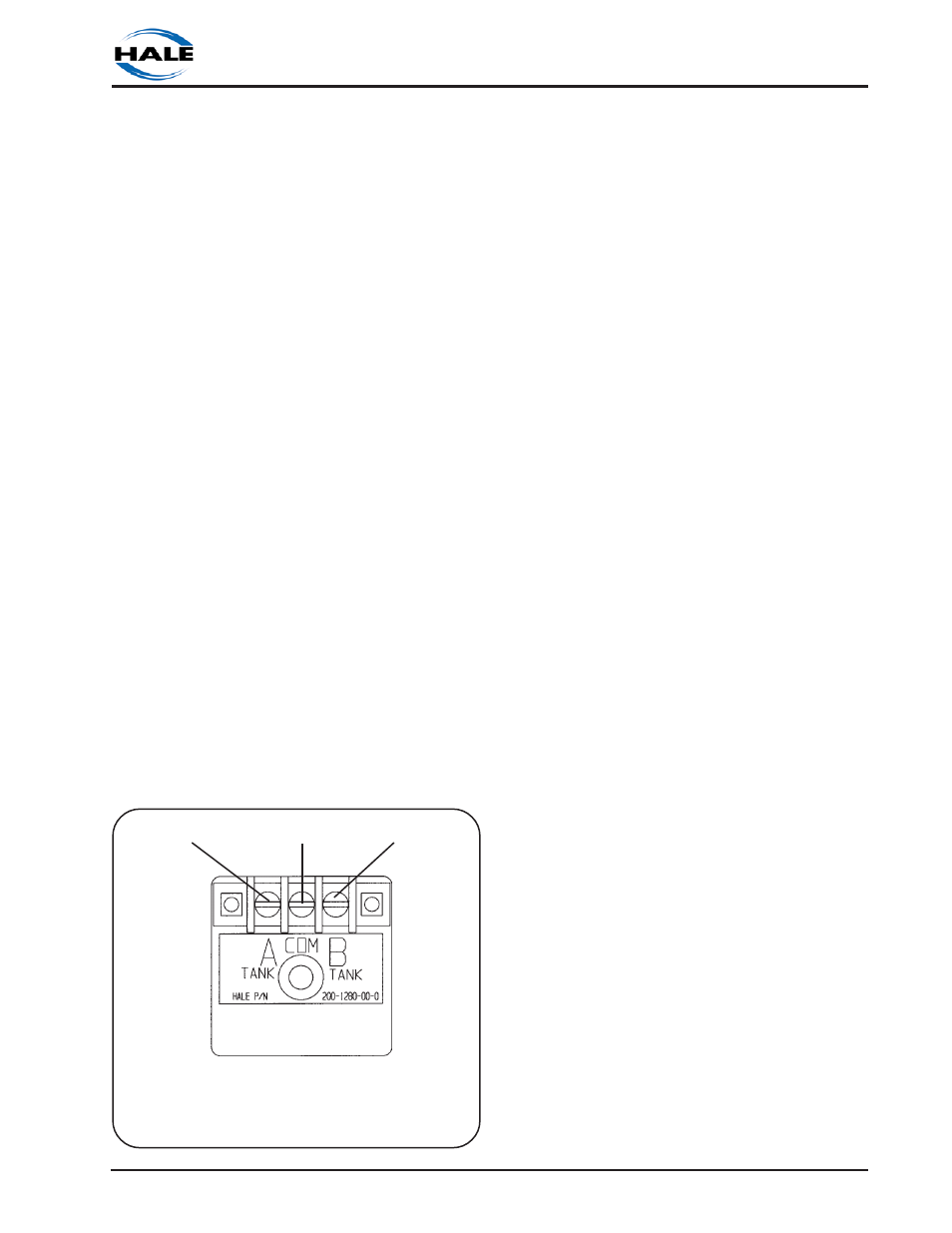

Figure 2-29. Low Tank Sensor A-B

Switchbox Connections

TANK B

TERMINAL

COMMON

TERMINAL

TANK A

TERMINAL

A-B SWITCHBOX MOUNTED ON

FOAM PUMP