Correct incorrect – Hale 5.0 FoamLogix User Manual

Page 45

ΙΙ

-15

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

For proper installation, the flowsensor

requires the use of a spacer and eight

stainless steel internal hex head screws.

Four 6 – 32 x ½ inch screws attach the

spacer to the saddle clamp mount, and

four 6 – 32 x ¾ inch screws with lockwashers

attach the paddlewheel to the spacer.

Align the spacer to the saddle clamp

mount by arranging the indexing pin of the

saddle clamp with the indexing hole of the

spacer. Use four ½ inch machine screws

without lockwashers to secure the two

pieces. Torque to 8.5 inch pounds.

Align the paddlewheel indexing pin to the

indexing hole in the spacer, secure using

four ¾ inch screws and lockwashers.

Torque to 7.5 inch pounds.

Apply a small amount of grease to the

saddle clamp gasket before the final

installation of the assembly onto the pipe.

Tighten the saddle clamp onto the pipe

firmly.

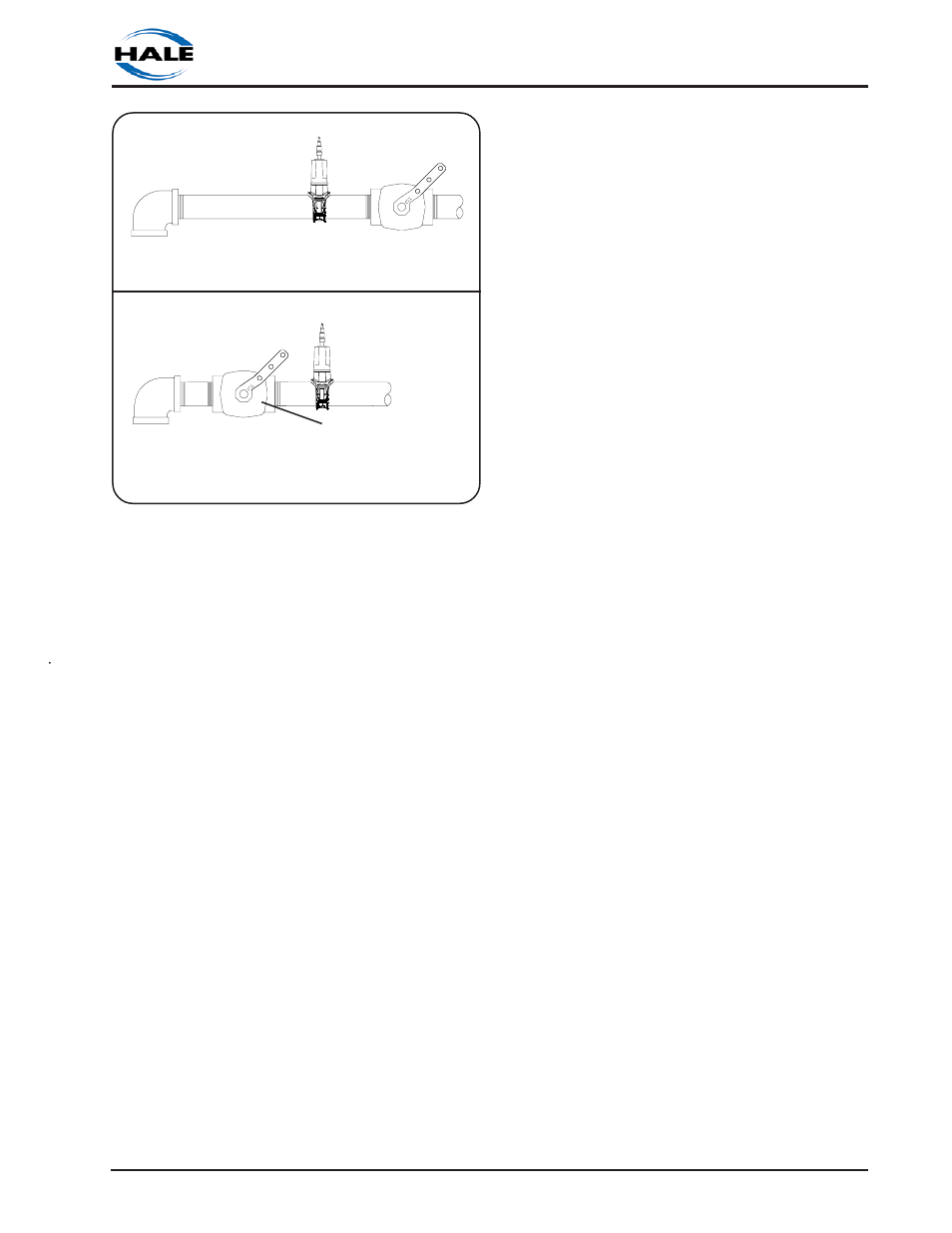

The paddlewheel should be installed as

close to upright as possible within the range

shown in figure 2-8. Do not let the

flowsensor rotate more than 85 degrees in

Figure 2-10. Flowsensor Placement

WATER

INLET

WATER

INLET

VALVE OR

FITTING AFTER

FLOWSENSOR

VALVE OR FITTING BEFORE

FLOWSENSOR WITH LESS THAN 5X

THE PIPE DIAMETER BETWEEN

AT LEAST 5X THE PIPE

DIAMETER BETWEEN

VALVE OR FITTING AND

FLOWSENSOR

CORRECT

INCORRECT

either direction for proper operation.

FOAM PUMP FLUSH SYSTEM

When dual foam tanks are installed on the

apparatus, flushing water must be provided

to flush the system of foam concentrate

after use of some foam concentrate types

to prevent possible reactions. The Hale ADT

and Hale MDT

II each have provisions for

connecting flushing water to the foam

concentrate injection system.

If a single foam concentrate tank system is

installed on the apparatus the Hale MST

provides a selector valve and gives the

system flush capabilities for NFPA

compliance. A fitting provided on the Hale

MST makes connection of flushing water

simple.

When the Hale FoamLogix is installed with

the "no tank" option the system installer must

provide flushing water supply to comply

with NFPA standards.

Flushing water hose should have a minimum

of ½ inch (12 mm) inside diameter and be

capable of withstanding the maximum fire

pump discharge pressure, 500 PSI (34 BAR)

minimum. The flush water supply should be

provided from one of the pressure taps on

the discharge of the fire pump. It is

recommended that a check valve be

installed at the pressure tap to prevent

contamination. Flush water thread

connections on the ADT are ½ inch NPT and

on the Hale MDT

ΙΙ

and Hale MST they are ¼

inch NPT. The system installer must provide

proper fittings for these connections.

FOAM CONCENTRATE PLUMBING

Foam concentrate plumbing consists of the

foam concentrate suction hose, foam

strainer, foam concentrate discharge hose

and check valve/injector fitting.

CAUTION: Make sure the foam tank and

foam concentrate suction hoses are

clean before making final connection to

foam pump. Flush tank and hoses prior