Low level sensor wiring, Ιι -38, Fnpt x – Hale 5.0 FoamLogix User Manual

Page 68: Tube fitting and strain relief gland. attach the

ΙΙ

-38

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

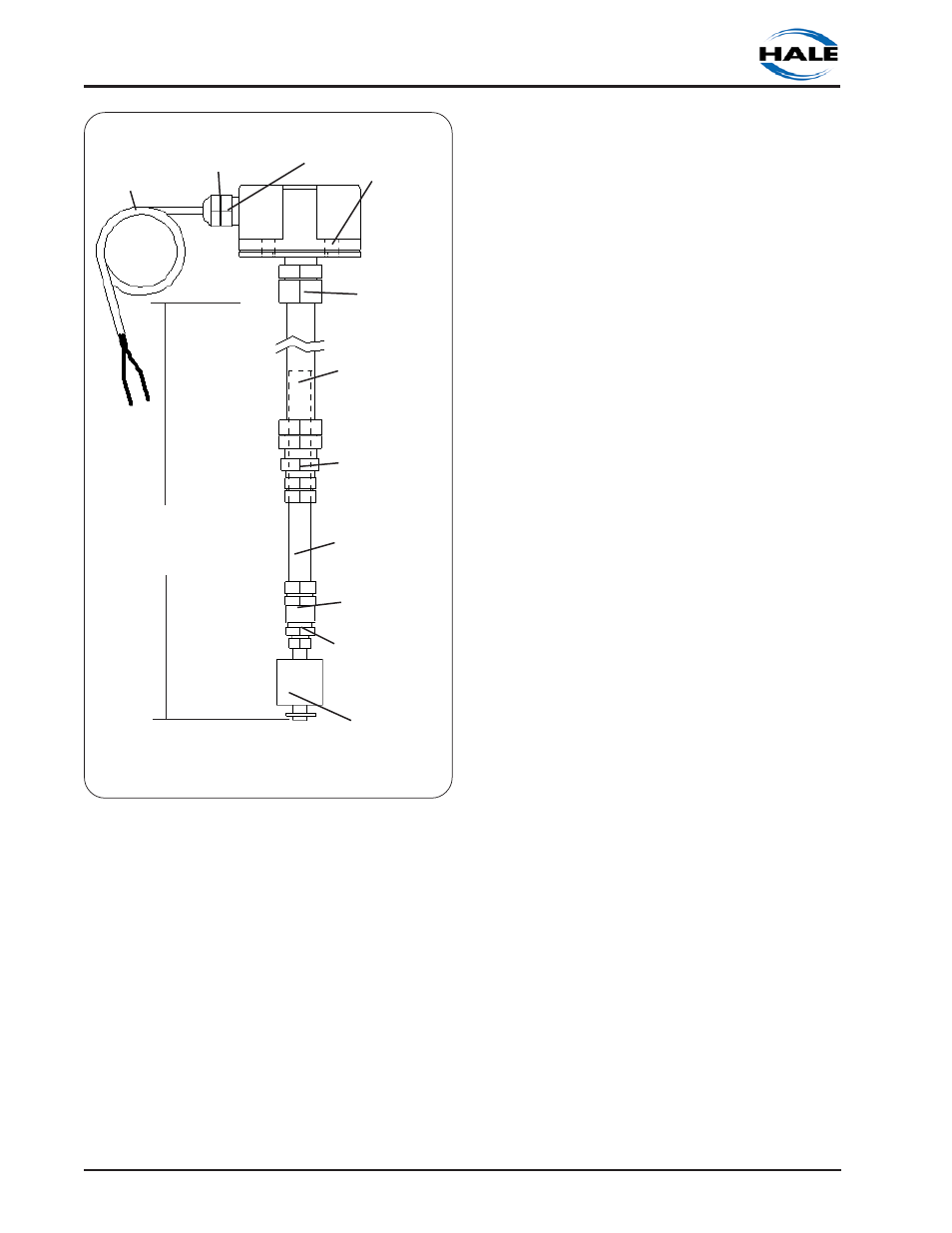

Figure 2-28. Top Mount Low Tank Switch

Assembly Component Identification

STRAIN

RELIEF

STRAIN RELIEF

GLAND NUT

FLANGE AND

GASKET

SENSOR

¼ NPT X

1

/

8

FNPT

BUSHING

¼ FNPT X ½ TUBE

FITTING

½ TUBE X

5

/

8

TUBE UNION

1

/

2

FNPT X

5

/

8

TUBE

FITTING

5

/

8

INCH O.D.

STAINLESS TUBE

½ INCH O.D.

STAINLESS TUBE

SENSOR

WIRE

3) Using a tubing cutter, remove the

required length of tube from the end of

each tube. Deburr the cuts when

complete.

4) Install a new ½ compression ferrule

on the end of the tube. Carefully thread

the sensor wire through the tube

assembly and attach the ¼ FNPT x ½

tube fitting with sensor attached to the

end of the tube. Tighten the ½ tube

compression nut.

5) Install a new

5

/

8

compression ferrule

on the end of the tube. Carefully thread

the sensor wire through the

3

/

8

FNPT x

5

/

8

tube fitting and strain relief gland.

Attach the

3

/

8

FNPT x

5

/

8

tube fitting and

strain relief to the end of the tube.

Tighten the

5

/

8

tube compression nut.

6) Slide the flange to the top of the 5/8

inch diameter tube and adjust the

telescoping section until the desired

length is achieved as measured from

the bottom of the flange to the bottom

of the sensor. Tighten the compression

fittings on the union to lock length.

CAUTION: When extending the low tank

sensor wires make sure the splices are

properly sealed using an adhesive filled

heat shrink tubing.

LOW LEVEL SENSOR WIRING

CAUTION: When extending the low tank

sensor wires make sure the splices are

properly sealed using an adhesive filled

heat shrink tubing.

SINGLE FOAM TANK SYSTEM

When a single foam tank system is installed

use minimum 16 AWG Type SXL or GXL (SAE

J1128) wire to extend the low tank sensor

wire to allow connection to the 2-wire

Packard WeatherPack connector on the

distribution box (see figure 2-23). Low tank

level sensors are not polarity sensitive

therefore terminal connections are not

specific.

If necessary, when making splices to extend

the low tank sensor wires make sure the

splices are sealed using an adhesive filled

heat shrink tubing. Where two wires exit the

heat shrink tubing pinch the tubing while

heating the tubing to make sure the

adhesive seals around both wires.

A connector kit (Hale P/N 546-1780-00-0) is

included that contains a Packard

WeatherPack 2-contact shroud half, two (2)

14-16 gage male terminals and two (2) 14-

16 gage cable seals. Assemble these

components to the end of the low tank

sensor wires. Snap the two halves of the

Packard WeatherPack connector together

making sure they are sealed.

MINIMUM LENGTH

WITHOUT CUTTING TUBE

SECTIONS 31-½ INCHES

(800 MM)