Don't, Figure 2-30. extra cable storage, Primary power supply connection – Hale 5.0 FoamLogix User Manual

Page 70: Table 2-1, Rfi/emi, Ιι -40

ΙΙ

-40

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

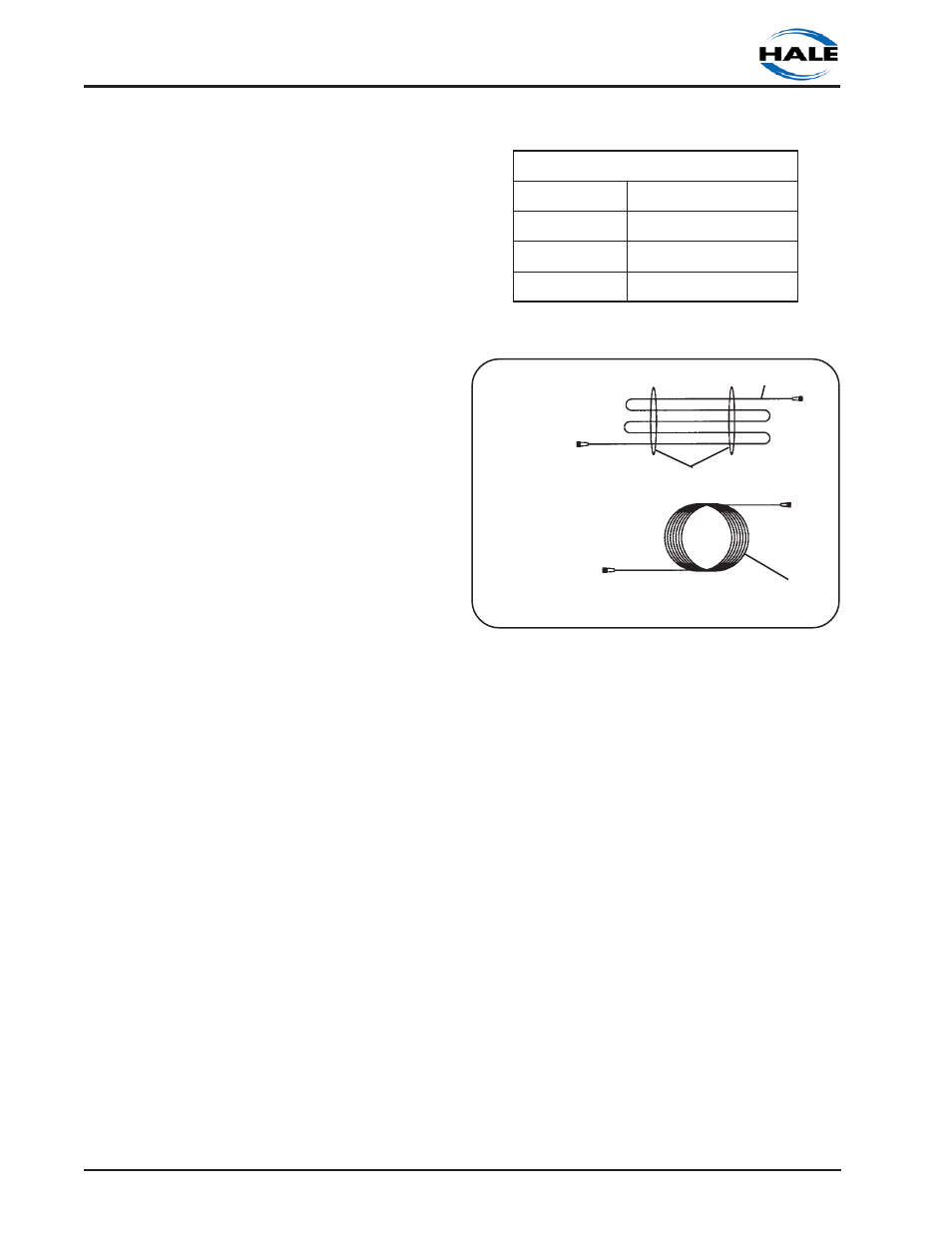

Figure 2-30. Extra Cable Storage

DON'T

MODULAR CABLE

MODULAR CABLE

DO

WIRE TIES

provided.

GROUND CONNECTION

Be sure the Hale FoamLogix system is

grounded to the chassis. Use a short length

of wide flat ground strap at least 1-¼ inches

(32 mm) wide and less than 18 inches (457

mm) long to reduce the potential of RFI

emitted by this connection. A stud labeled

NEG (—) is located on the distribution box to

attach the chassis ground strap to the Hale

FoamLogix system. (See figure 2-24) When

making the ground strap connections make

sure lugs are attached to the strap ends for

trouble free connections.

When the length of the ground strap

exceeds 18 inches (457 mm) use a wider

strap or a double thickness strap.

CAUTION: DO NOT connect the main

power lead to small leads that are

supplying some other device such as a

light bar or siren. The Hale FoamLogix

Model 3.3 and Model 5.0 require 60 AMP

minimum current. The Hale FoamLogix

Model 3.0 requires 40 AMP minimum

current.

PRIMARY POWER SUPPLY

CONNECTION

Make sure adequate switched electrical

power from the battery + terminal to the

battery connection stud on the distribution

box (see figure 2-24) is provided. Use 4

AWG minimum type SGX (SAE J1127)

battery cable directly to the battery,

battery switch or solenoids for cable runs up

to 6 feet (1.8 meters) long. Longer wire runs

may require larger battery cable for proper

operation. DO NOT connect power to the

same connection as the pump primer. The

following table provides recommended

cable size for various lengths of cable run.

Table 2-1

S

E

Z

I

S

E

L

B

A

C

R

E

W

O

P

Y

R

A

M

I

R

P

D

E

R

I

U

Q

E

R

0

.

5

&

3

.

3

s

l

e

d

o

M

h

t

g

n

e

L

m

u

m

i

x

a

M

m

m

(

G

W

A

4

2

)

s

s

e

L

r

o

)

M

8

.

1

(

t

F

6

m

m

(

G

W

A

0

2

)

)

M

6

.

4

(

t

F

5

1

o

t

)

M

8

.

1

(

t

F

6

m

m

(

G

W

A

0

0

2

)

r

e

g

n

o

L

r

o

)

M

6

.

4

(

t

F

5

1

RFI/EMI

Electrically shielded cables for control unit,

flowsensor, foam discharge multiplexing

display units and pressure transducers are

provided with the Hale FoamLogix system.

The cables are 100% electrically shielded to

eliminate the potential problem of EMI/RFI.

Proper installation of system components

and cables along with proper grounding will

limit radio interference caused by the Hale

FoamLogix system. Additionally, make sure

radio cables and hardware are not located

in the immediate area where Hale

FoamLogix equipment is mounted.

Make sure the flowsensor tee is grounded.

If metal piping is used sufficient grounding

may be present. However, Victaulic joints,

plastic pipe and rubber mounted pumps

interfere with proper grounding and an

additional ground strap may be required. If

necessary, connect a flat braided ground

strap at least ¼ inch (6 mm) wide from the

flowsensor tee to the apparatus frame to