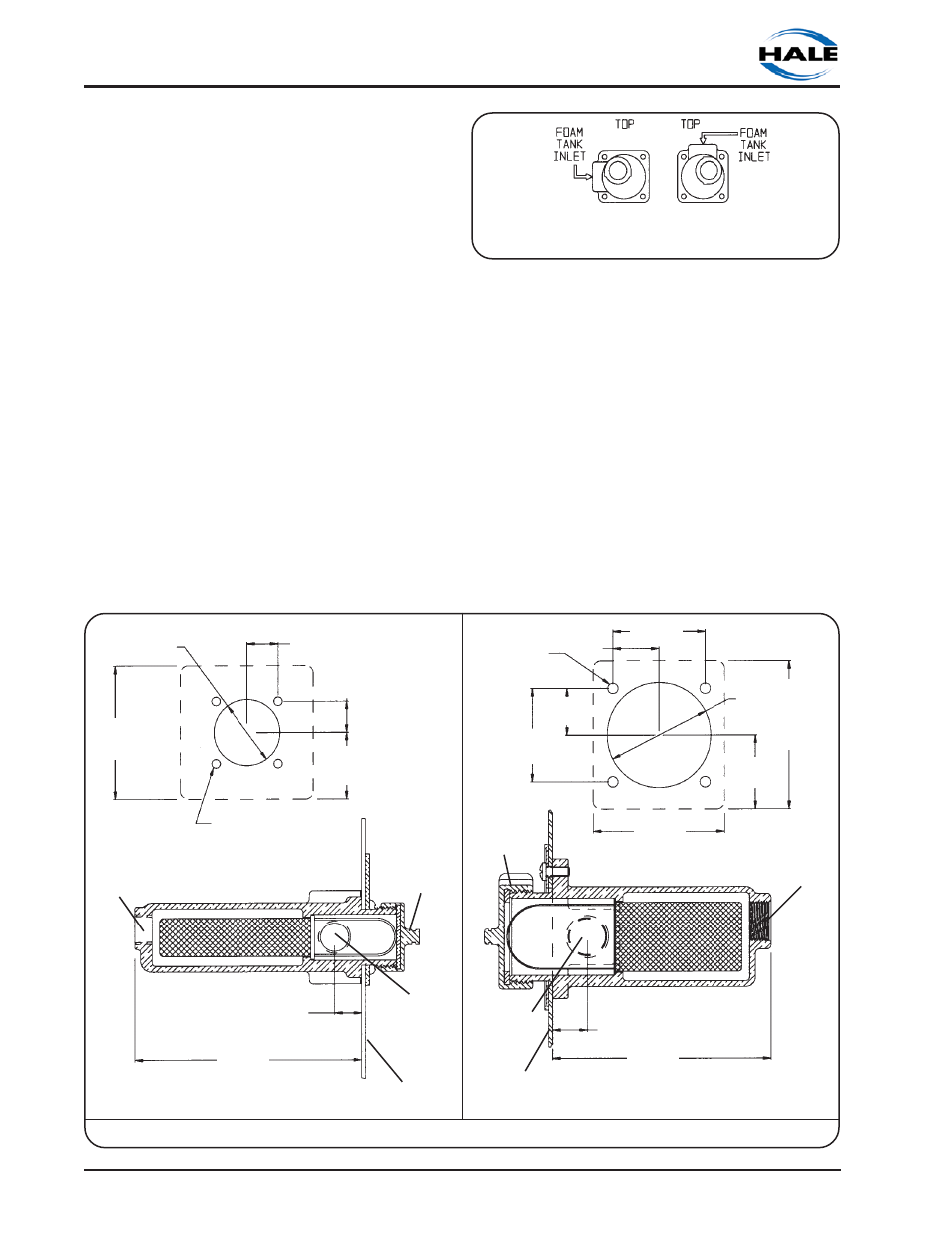

Fs15 strainer fs25 strainer, Figure 2-14. fs series strainer orientation, Ιι -18 – Hale 5.0 FoamLogix User Manual

Page 48

ΙΙ

-18

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

Figure 2-15. FS Series Strainer Mounting Dimensions

4.28 IN.

(109 MM)

3.00 IN.

(76 MM)

0.34 IN. (9 MM)

DIA. THRU HOLE

(4 PLACES)

1.00 IN.

(25 MM)

1.00 IN.

(25 MM)

1.50 IN.

(38 MM)

0.88 IN.

(22 MM)

1.13 IN.

(29 MM)

3.00 IN.

(76 MM)

1.50 IN.

(38 MM)

4.75 IN.

(121 MM)

2.38 IN.

(60 MM)

3.38 IN. (86 MM)

DIA. HOLE

7.09 IN.

(180 MM)

1 INCH NPT

THREADED

OUTLET

1 INCH

NPT

THREADED

INLET

2-½ INCH

NST CAP

¾ INCH NPT

THREADED

OUTLET

¾ INCH NPT

THREADED

INLET

1-½ INCH

NST CAP

7.34 IN.

(186 MM)

0.28 IN. (7 MM)

DIA. THRU HOLE

(4 PLACES)

2.13 IN. (54 MM)

DIA. HOLE

2.14 IN.

(54 MM)

4.28 IN.

(109 MM)

TYP.

OPERATOR

PANEL

OPERATOR

PANEL

FS15 STRAINER

FS25 STRAINER

inlet of the Hale MDT

ΙΙ

, Hale MST or

foam concentrate pump or correct

fitting on Hale ADT.

FS SERIES STRAINER

When a pressurized water flush is provided

to the strainer from one of the discharges

the use of Hale FS series strainers is required.

The plumbing exposed to the flush water

pressure must be rated at or above the

operating pressure of all other discharge

plumbing components. [500 PSI (34 BAR)

minimum]

The following procedures are provided for

installation of FS series strainers:

1. Choose a location on the apparatus

that allows gravity feed from the foam

tank to the strainer inlet and from the

strainer outlet to the foam pump suction

connection.

NOTE: When selecting the strainer

location make sure there is sufficient

space behind the pump panel to permit

attaching hoses and fittings. Make sure

the inlet connection port is oriented as

shown in figure 2-14 when installing the

FS series strainer.

2. Remove the strainer cap, mounting

screws and nameplate from the strainer

assembly.

3. Using the nameplate as a guide, or refer

to the diagrams in figure 2-15, mark

Figure 2-14. FS Series Strainer Orientation

LOOKING FROM BACK OF STRAINER