Table 1. maximum foam solution flows – Hale 5.0 FoamLogix User Manual

Page 10

Ι−

4

Section

I

: Description

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

concentrate tanks. Examples of the various

Hale Foam system configurations are shown

in figures 1-1 through 1-7 at the end of this

section.

The available Air Dual Tank (ADT) valve for

the Hale Foam system is an air operated

foam tank selector valve that provides

selection of foam concentrate dependent

on fire ground operational demands. The

ADT is an integral part of the foam pump

and provides an electrical interlock for the

low tank level sensors and concentrate

injection rate. A panel mounted selector

toggle switch with indicator lights controls

foam concentrate tank selection and shows

which foam concentrate tank is in use.

The Manual Dual Tank (MDT

ΙΙ

) selector

valve is available for the Hale Foam systems

with dual tanks. The MDT

ΙΙ

is a panel

mounted manually operated selector that

provides selection of foam concentrate

dependent on fire ground operational

demands. The MDT

ΙΙ

also provides an

electrical interlock for the low tank level

sensors and concentrate injection rate. It

should be noted that the MDT

ΙΙ

is not

suitable for top mount operator panel

installations and some side operator panels

due to gravity feed requirements of foam

concentrate to the foam pump.

Selection of the desired foam concentrate

tank with the ADT panel mounted toggle

switch or MDT

ΙΙ

selector will automatically

change the foam concentrate injection

rate to the preset default rate for the

selected foam tank. No further operator

intervention is required.

Single tank foam systems can be

configured with a Manual Single Tank (MST)

selector which provides a flush function

connection to the foam system electronic

controls.

The ADT, MDT

ΙΙ

and MST all provide the

check valves and connection points to

provide foam pump flushing capabilities.

Strainers available for Hale FoamLogix Foam

systems protect the foam pump from debris

that might accumulate in the foam

concentrate tank. The standard in-line

strainer/valve assembly has a composite

nonmetallic housing with stainless steel

mesh strainer element. It is provided with a

service shutoff valve, mounting bracket.

The strainer and valve have 1-1/4 NPT

threads and is supplied with fittings for

connection of either 1-1/4 inch (32 mm) ID,

1 inch (25 mm) ID or ¾ inch (19 mm) ID

foam concentrate suction hose. The in-line

strainer/valve assembly is suitable for use

with both Class A and Class B foam

concentrates. The in-line strainer/valve

assembly is designed for installations where

the strainer is mounted in the foam pump

suction line and IS NOT subject to flushing

water pressure.

Hale FS series strainers are panel mounted

strainers with a 500 PSIG (34 BAR) pressure

rating suitable for use where flushing water

pressure will go through the strainer. The

FS15 strainer has ¾ inch NPT connection

ports and a 1-½ inch NST cap and is suitable

for use with Class A and low viscosity Class B

foam concentrates. The FS25 strainer has 1

inch NPT connection ports and a 2-½ inch

NST cap and is suitable for use with both

Class A and Class B foam concentrates.

All Hale FoamLogix Foam systems require a

flowsensor for operation.

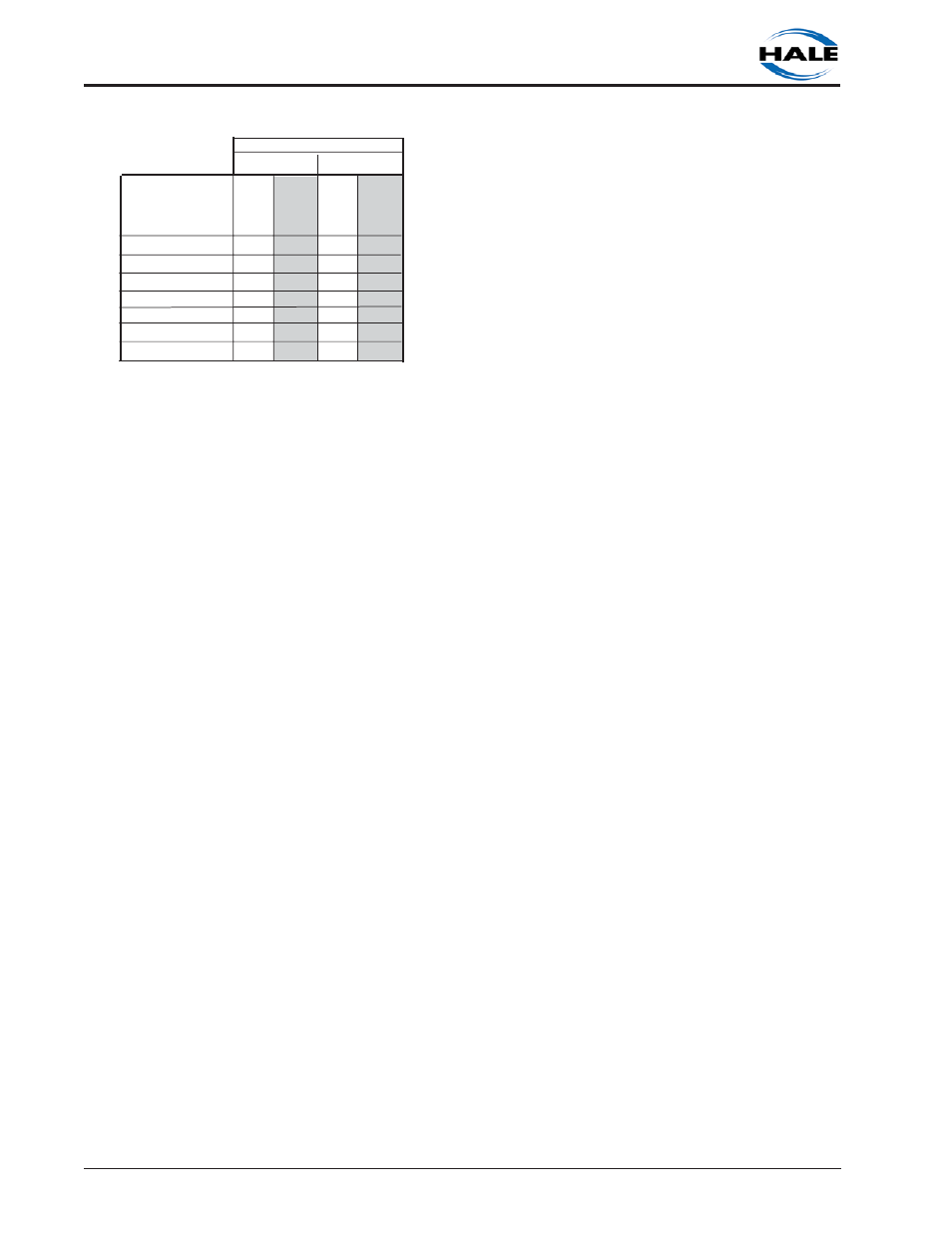

WATER FLOW

MODEL 3.3

MODEL 5.0

FOAM

CONCENTRATE

(%)

0.1

0.2

0.3

0.5

1

3

6

GPM

LPM

3300 12491

1650

6245

1100

4164

660

2498

330

1249

110

416

55

208

GPM

LPM

5000 18925

2500

9463

1667

6310

1000

3785

500

1893

167

632

83

314

Table 1. Maximum Foam Solution Flows