Correct incorrect – Hale 5.0 FoamLogix User Manual

Page 49

ΙΙ

-19

ROTARY GEAR PUMP

ELECTRONIC FOAM PROPORTIONING SYSTEM

Section

II

: Installation

holes for mounting the foam strainer.

The holes for the FS15 strainer mounting

screws are 9/32 inch (7 mm) and the

holes for FS25 strainer screws are 11/32

inch (9 mm) diameter. Additionally a

hole of sufficient size for the cap threads

to clear the panel is required. [FS15

strainer 2.13 inches (54 mm) and FS25

strainer 3.38 inches (86 mm)]

4. Select appropriate fittings for

attachment of the hoses to the strainer.

The fittings and hoses chosen must be

capable of withstanding the vacuum

generated by the foam pump [23

inches (584 mm) Hg] and the maximum

flushing water pressure [500 PSI (34

BAR)].

When using an FS15 strainer use ¾ inch

NPT x ¾ inch hose fittings.

When using an FS25 strainer use 1 inch

NPT x 1 inch hose fittings.

Before assembly coat all fitting threads

with a suitable thread sealant (Do not

use Teflon tape). Install the fittings into

the strainer and tighten securely.

5. Make sure the strainer is oriented as

shown in figure 2-14 and secure the

strainer body and nameplate to the

apparatus with the screws provided.

Install the cap on the strainer.

6. Install the hose from the foam tank

outlet to the inlet of the strainer. The

inlet of the strainer is closer to the

operator panel and is oriented as shown

in figure 2-14. Wetting the ends of the

hose and fittings will help ease

installation on the hose fittings.

CAUTION: Make sure the foam tank and

foam concentrate suction hoses are

clean before making final connection to

foam pump. Flush tank and hoses prior

to making connection.

7. Install the hose from the strainer outlet to

the inlet of the Hale FoamLogix foam

pump or selector valve.

CHECK VALVE/INJECTOR FITTING

The Hale check valve/injector fitting

supplied with the Hale FoamLogix system

meets NFPA requirements for a non-return

device in the foam injection system to

prevent back flow of water into the foam

concentrate tank. When properly installed

the brass and stainless steel construction

check valve/injector fitting ensures foam

concentrate is injected into the center of

the water flow for better mixing.

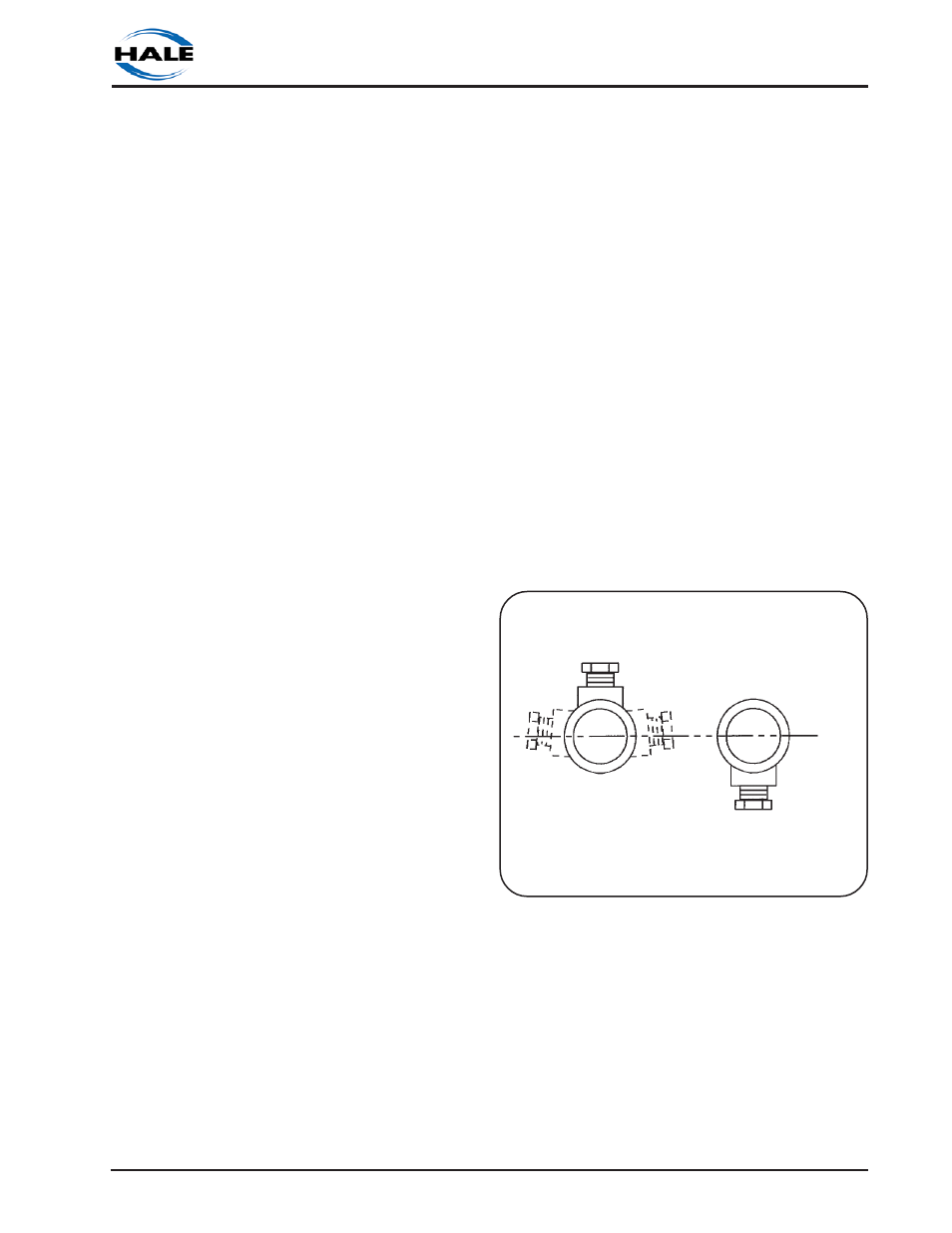

NOTE: Always position the check valve/

injector fitting at a horizontal or higher

angle to allow water to drain away from

the fitting (see figure 2-16). This will avoid

sediment deposits or the formation of an

ice plug.

The check valve/injector fitting MUST be

mounted in a location that is common to all

discharges which require foam concentrate

(see figure 2-18). The Hale FoamLogix

system does not permit a separate injection

point for each foam capable discharge.

The check valve/injector fitting has 1 inch

NPT threads on the outside to fit into the 1

CORRECT

INCORRECT

CHECK VALVE/INJECTOR FITTING

BELOW HORIZONTAL PLANE

Figure 2-16. Check Valve/Injector Fitting

Position

CHECK VALVE/INJECTOR FITTING

ABOVE HORIZONTAL PLANE