3 lubrication – Epson 440 User Manual

Page 155

EPSON Stylus Color 440/640/740

Revision A

Chapter 6

Maintenance

155

6.1.3 Lubrication

The type and amount of oil and grease used to lubricated the printer

parts are determined based on the results of internal evaluations.

Therefore, be sure to apply the specified type and amount of oil and

grease to the specified part of the printer mechanism during servicing.

C A U T I O N

Never use oil and the grease other than those

specified in this manual. Use of different types of

lubricant can damage the printer and the

components.

Never apply larger amount of lubricant than specified

in this manual.

Table 6-1. Specified Lubricants

Type

Name

EPSON Code

Supplier

Grease

G-26

B702600001

EPSON

Oil

O-12

1038991

EPSON

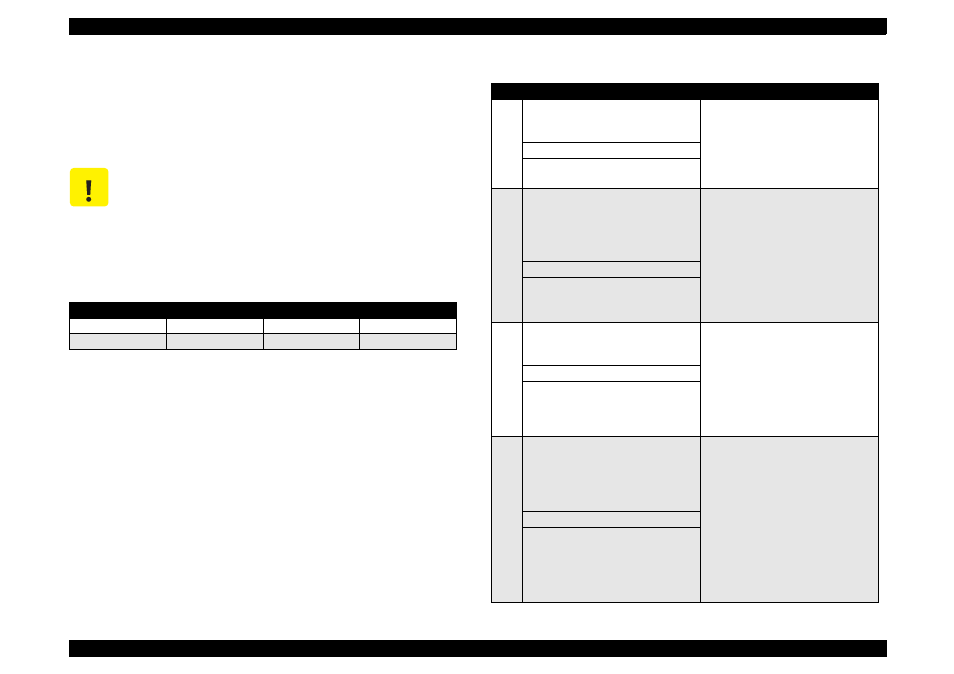

Table 6-2. Lubrication Point

No.

Standard

Remarks

1

Contact between “ROLLER, PF” and

“PAPER GUIDE, REAR”

Do not put grease around the paper

path.

Use a syringe to apply it.

Apply grease while rotating “GEAR,

67.2”.

A half turn of “ROLLER, PF”

2

Contact points between “PAPER

GUIDE, FRONT” and each roller:

“ROLLER, PF” (1 point)

“ROLLER, EXIT” (2 points)

Lubricate the contact points between

the hooks on “PAPER GUIDE,

FRONT” and each roller.

Avoid applying grease around the

paper path.

Use a syringe to apply it.

10-mm long

2-mm long

3

Contact points between the carriage

assembly and “FRAME, UPPER”

Verify that the carriage moves

smoothly after lubricating it.

Use a syringe to apply it.

Range from the HP sensor

installation point to the point where

“GUIDE PLATE, CABLE” is attached.

4

Gears:

“GEAR, 67.2”

“COMBINATION GEAR, 8, 14.4”

“GEAR, 23.2”

Rotate the gears after applying

grease to evenly distribute it.

Use a syringe to apply it.

1/4 of gear tooth

1/3 of gear tooth

1/3 of gear tooth

1/3 of gear tooth